Method for preparing monophenol chemicals by catalyzing lignin depolymerization through metal organic framework material derivative loaded ruthenium

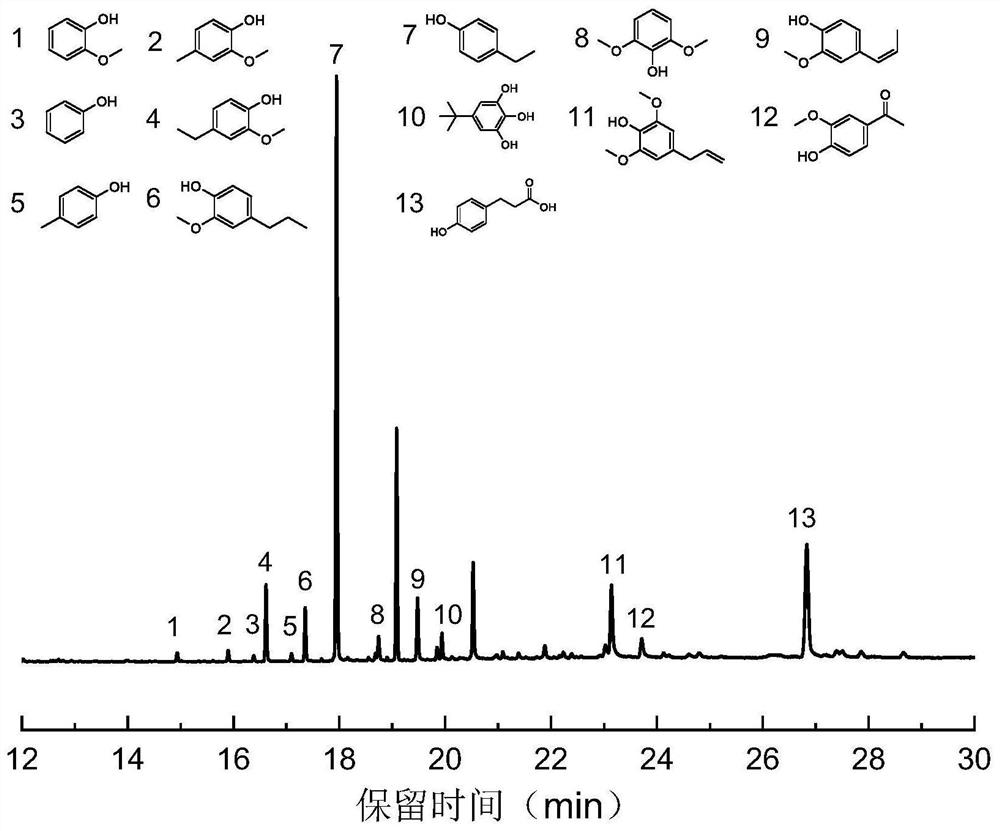

A metal-organic framework and derivative technology, which is used in the field of biomass degradation, metal-organic framework material derivatives supported ruthenium catalyzed lignin conversion to prepare monophenolic chemicals, and can solve the problems of catalyst performance degradation, catalyst susceptibility to deactivation, etc. , to achieve the effect of high conversion rate, lignin conversion rate and single-classification chemical yield improvement, and simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

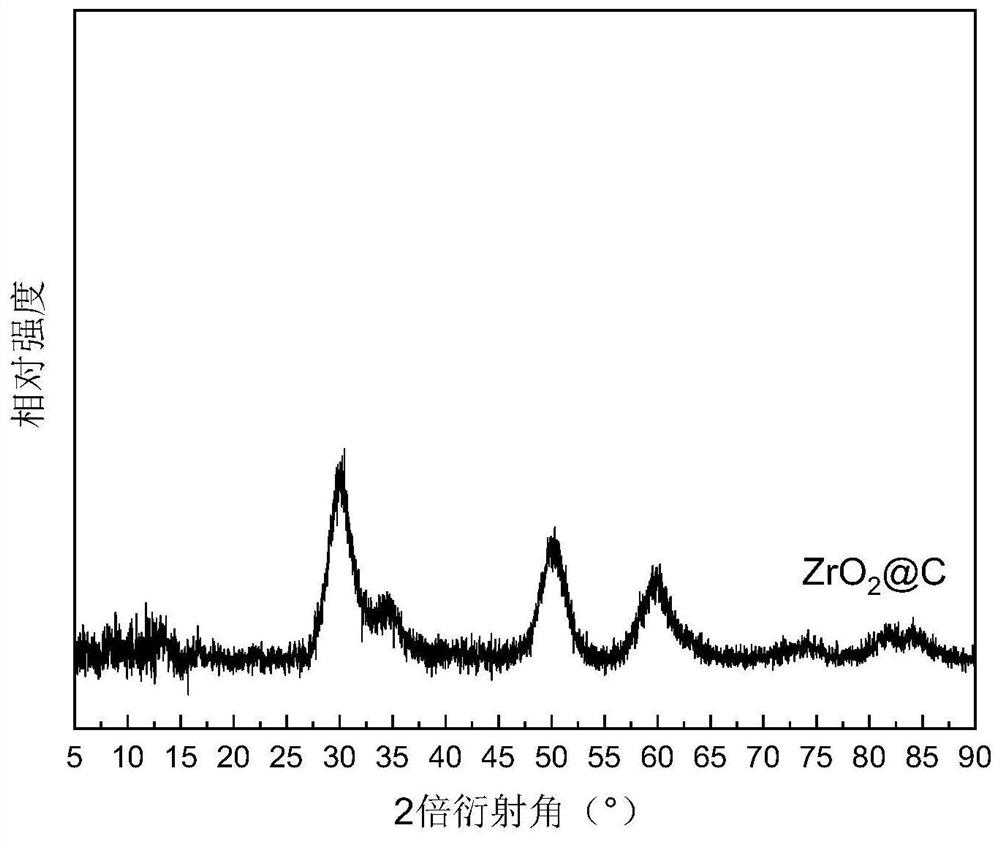

[0035] Example 1: 3wt.%Ru / ZrO 2 Preparation of @C catalyst

[0036] Zirconium-based metal-organic framework derivatives supported ruthenium-based metal catalysts through a two-step process:

[0037] (1) ZrO 2 Preparation of @C carrier: Weigh 1.16g of ZrCl with a purity of 99.9% 4 Solid, 0.83g of PTA (terephthalic acid) solid with a purity of 99%, the two were added to 250mL of a DMF solution with a purity of 99.5%, and 25mL of acetic acid with a purity of 99.5% was added. The prepared reaction liquid system was ultrasonicated for 30 min, transferred to a reaction vessel, and reacted at 120° C. for 24 h. After the reaction was completed, the reaction system was cooled to room temperature and centrifuged to obtain a white solid. The obtained white solid was washed several times with DMF, ethanol, and deionized water respectively, dried overnight in a vacuum oven, and ground to obtain a white powder, which is the carrier precursor. Transfer the white powder to a tube furnace...

Embodiment 2

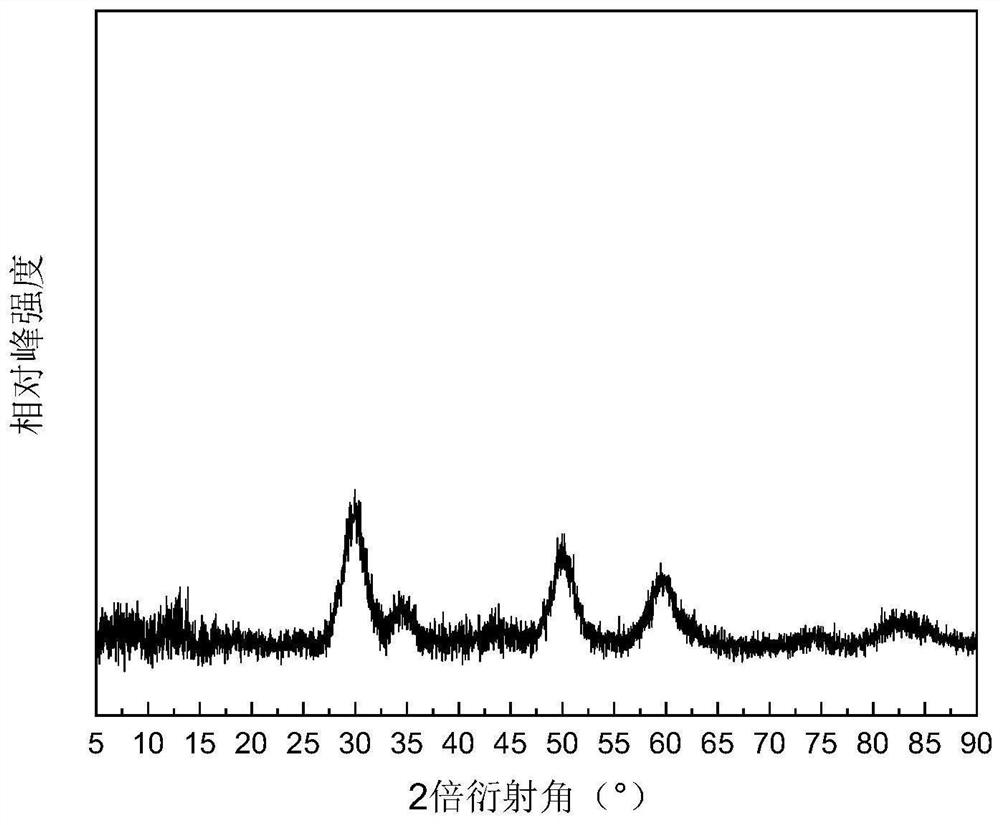

[0040] Example 2: 3wt.%Ru / ZrO 2 Preparation of @C catalyst

[0041] Zirconium-based metal-organic framework derivatives supported ruthenium-based metal catalysts through a two-step process:

[0042] (1) ZrO 2 Preparation of @C carrier: Weigh 1.16g of ZrCl with a purity of 99.9% 4 Solid, 0.83g of PTA solid with a purity of 99%, the two were added to 250mL of a DMF solution with a purity of 99.5%, and 25mL of acetic acid with a purity of 99.5% was added. The prepared reaction liquid system was ultrasonicated for 30 min, transferred to a reaction vessel, and reacted at 120° C. for 24 h. After the reaction was completed, the reaction system was cooled to room temperature and centrifuged to obtain a white solid. The obtained white solid was washed several times with DMF, ethanol, and deionized water respectively, dried overnight in a vacuum oven, and ground to obtain a white powder, which is the carrier precursor. Transfer the white powder to a tube furnace and calcinate at 55...

Embodiment 3

[0044] Example 3: 0.5wt.%Ru / ZrO 2 Preparation of @C catalyst

[0045] Zirconium-based metal-organic framework derivatives supported ruthenium-based metal catalysts through a two-step process:

[0046] (1) ZrO 2 Preparation of @C carrier: Weigh 1.16g of ZrCl with a purity of 99.9% 4 Solid, 0.83g of PTA solid with a purity of 99%, the two were added to 250mL of a DMF solution with a purity of 99.5%, and 25mL of acetic acid with a purity of 99.5% was added. The prepared reaction liquid system was ultrasonicated for 30 min, transferred to a reaction vessel, and reacted at 120° C. for 24 h. After the reaction was completed, the reaction system was cooled to room temperature and centrifuged to obtain a white solid. The obtained white solid was washed several times with DMF, ethanol, and deionized water respectively, dried overnight in a vacuum oven, and ground to obtain a white powder, which is the carrier precursor. Transfer the white powder to a tube furnace and calcinate at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com