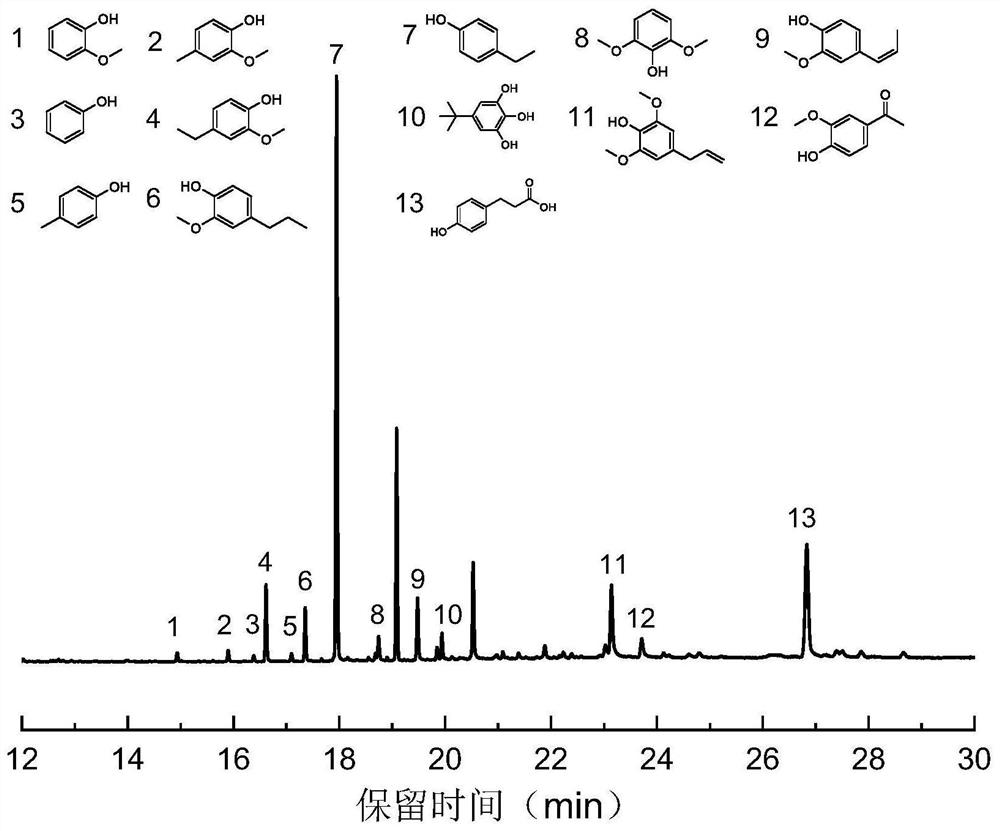

Method for preparing monophenolic chemicals by depolymerization of lignin catalyzed by metal-organic framework material derivatives loaded with ruthenium

A metal-organic framework and derivative technology, applied in the preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., to achieve the effects of simple process conditions, excellent cycle performance, and low coke rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

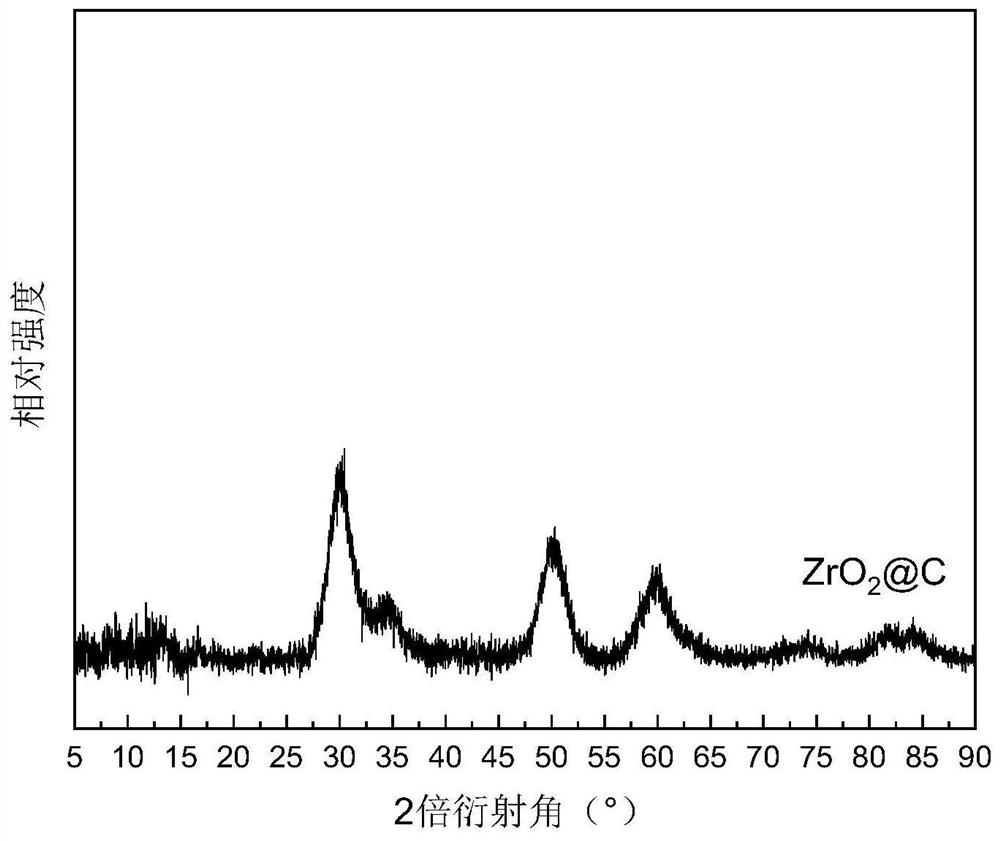

[0035] Zirconium-based metal-organic framework derivatives supported ruthenium-based metal catalysts through a two-step process:

[0036] (1) ZrO 2 Preparation of @C carrier: Weigh 1.16g of ZrCl with a purity of 99.9% 4 Solid, 0.83g of PTA (terephthalic acid) solid with a purity of 99%, the two were added to 250mL of a DMF solution with a purity of 99.5%, and 25mL of acetic acid with a purity of 99.5% was added. The prepared reaction liquid system was ultrasonicated for 30 min, transferred to a reaction vessel, and reacted at 120° C. for 24 h. After the reaction was completed, the reaction system was cooled to room temperature and centrifuged to obtain a white solid. The obtained white solid was washed several times with DMF, ethanol, and deionized water respectively, dried overnight in a vacuum oven, and ground to obtain a white powder, which is the carrier precursor. Transfer the white powder to a tube furnace and calcinate at 550°C for 4 hours under the protection of an ...

Embodiment 2

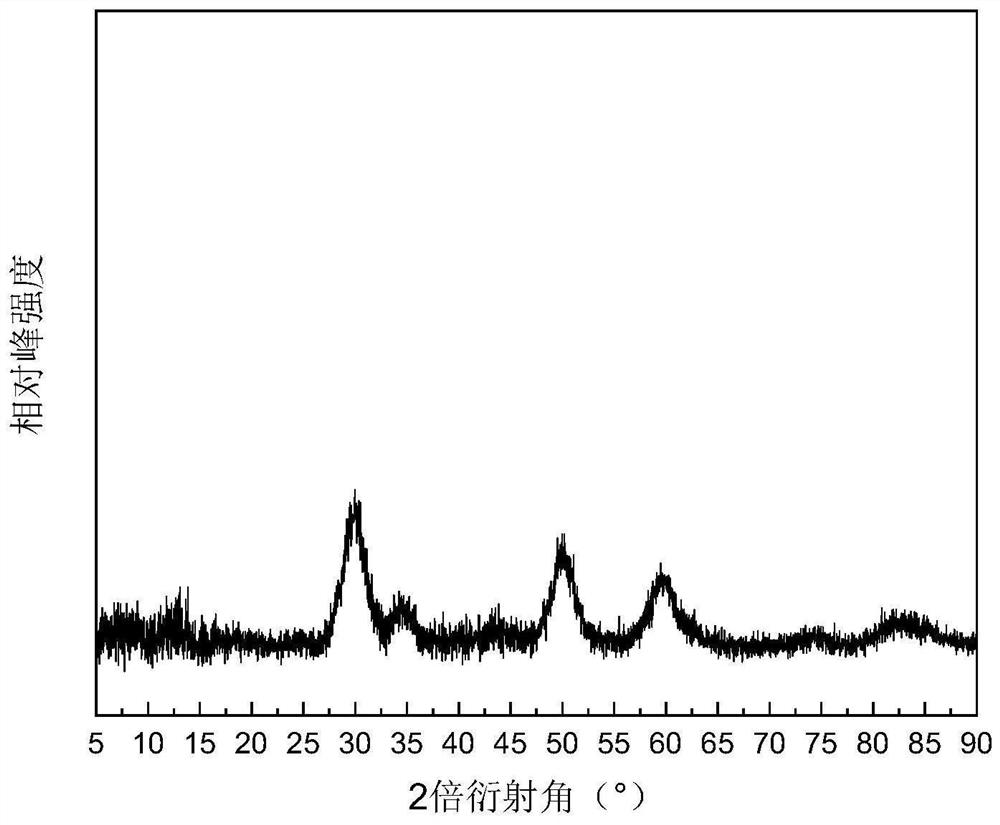

[0040] Zirconium-based metal-organic framework derivatives supported ruthenium-based metal catalysts through a two-step process:

[0041] (1) ZrO 2 Preparation of @C carrier: Weigh 1.16g of ZrCl with a purity of 99.9% 4 Solid, 0.83g of PTA solid with a purity of 99%, the two were added to 250mL of a DMF solution with a purity of 99.5%, and 25mL of acetic acid with a purity of 99.5% was added. The prepared reaction liquid system was ultrasonicated for 30 min, transferred to a reaction vessel, and reacted at 120° C. for 24 h. After the reaction was completed, the reaction system was cooled to room temperature and centrifuged to obtain a white solid. The obtained white solid was washed several times with DMF, ethanol, and deionized water respectively, dried overnight in a vacuum oven, and ground to obtain a white powder, which is the carrier precursor. Transfer the white powder to a tube furnace and calcinate at 550°C for 4 hours under the protection of an inert gas to obtain ...

Embodiment 3

[0044] Zirconium-based metal-organic framework derivatives supported ruthenium-based metal catalysts through a two-step process:

[0045] (1) ZrO 2 Preparation of @C carrier: Weigh 1.16g of ZrCl with a purity of 99.9% 4 Solid, 0.83g of PTA solid with a purity of 99%, the two were added to 250mL of a DMF solution with a purity of 99.5%, and 25mL of acetic acid with a purity of 99.5% was added. The prepared reaction liquid system was ultrasonicated for 30 min, transferred to a reaction vessel, and reacted at 120° C. for 24 h. After the reaction was completed, the reaction system was cooled to room temperature and centrifuged to obtain a white solid. The obtained white solid was washed several times with DMF, ethanol, and deionized water respectively, dried overnight in a vacuum oven, and ground to obtain a white powder, which is the carrier precursor. Transfer the white powder to a tube furnace and calcinate at 550°C for 4 hours under the protection of an inert gas to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com