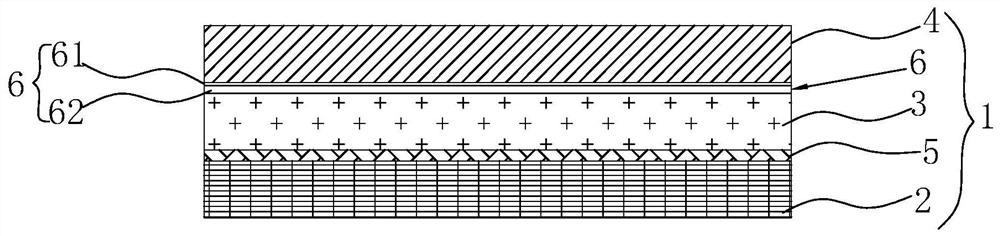

Flame-retardant floor and preparation method thereof

A technology of flooring and flame retardants, applied in chemical instruments and methods, wood layered products, textiles, etc., can solve problems such as health hazards, and achieve the effects of low cost, good flame retardancy, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

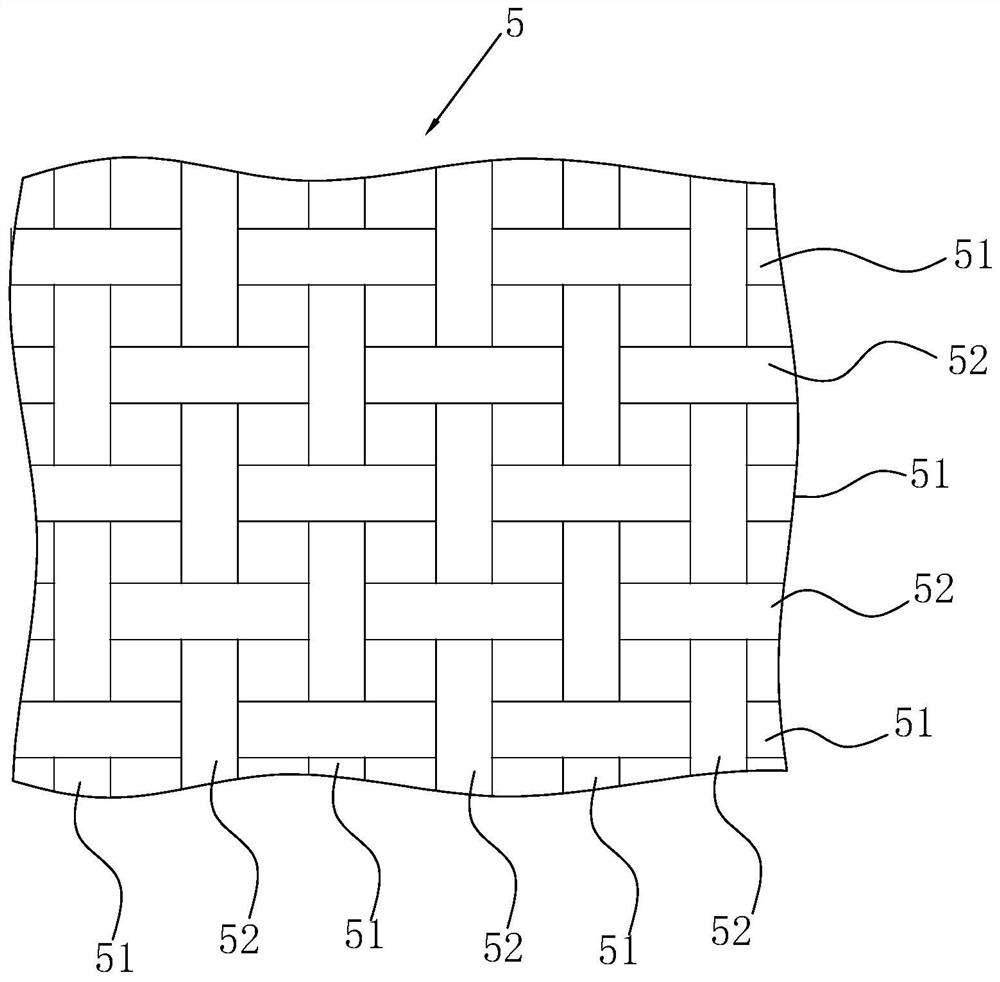

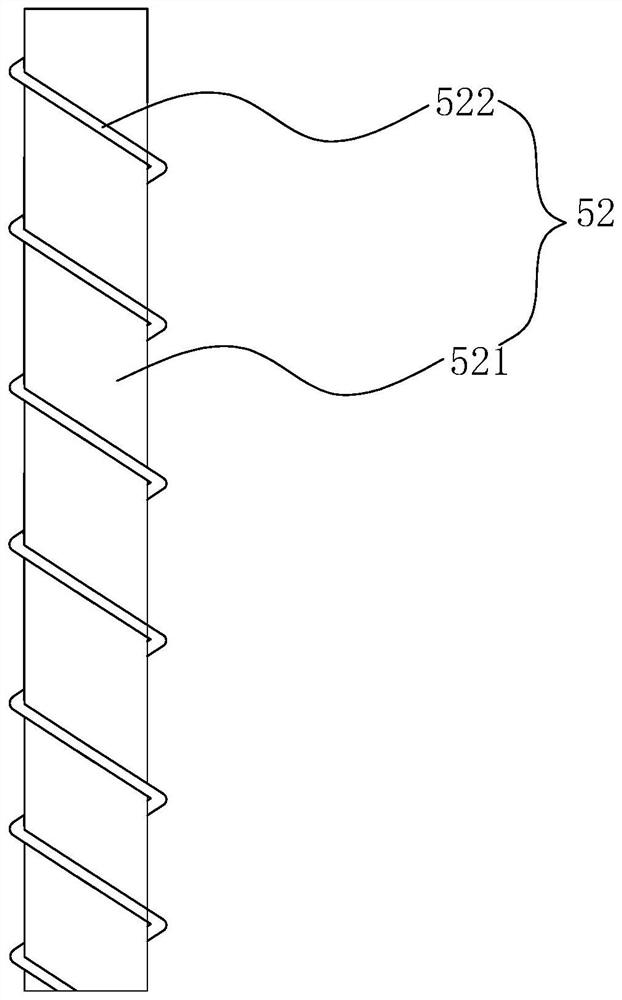

[0046] Preparation of the first reinforced mesh: first, S glass fiber and aramid fiber are twisted to form the first composite wire, and the chitin fiber is spirally wound around the ultrafine PET / SS composite phase-change energy storage fiber to form the second composite wire. The composite yarn and the second composite yarn are warp yarns, and the first composite yarn and the second composite yarn are weft yarns, which are woven into a first reinforcing mesh with a warp and weft density of 40 threads / 10cm by a flat loom.

preparation example 2

[0048] Preparation of the second reinforced mesh cloth: first, HT carbon fiber and Kevlar fiber are twisted into the third composite thread, and the third composite thread is used as the warp and weft yarn, and the second mesh with a warp and weft density of 40 / 10cm is woven into a flat loom. Reinforced mesh.

preparation example 3

[0050] Preparation of flame-retardant glue: Weigh 1000g water-based polyurethane glue, 85g magnesium dioxide, 89g aluminum dioxide, 22g liquid rare earth flame retardant, 42g nano-silica, 5g multi-walled carbon nanotube MWNT, first mix the water-based polyurethane glue In the reaction kettle, the stirring speed is controlled at 300 rpm, magnesium dioxide, aluminum dioxide and liquid rare earth flame retardant are added in sequence, the stirring speed is controlled at 500 rpm, after stirring for 3 minutes, nano-silica and poly Wall carbon nanotubes MWNT, the stirring speed is increased to 800 rpm, stirred for 2 minutes, the rotational speed is reduced to 300 rpm, stirred for 10 minutes, and a flame-retardant glue is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com