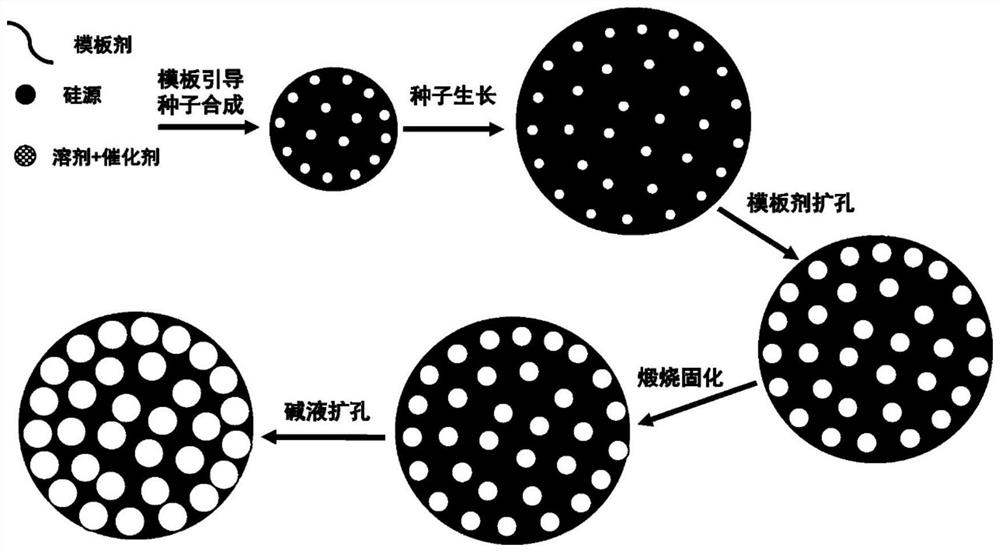

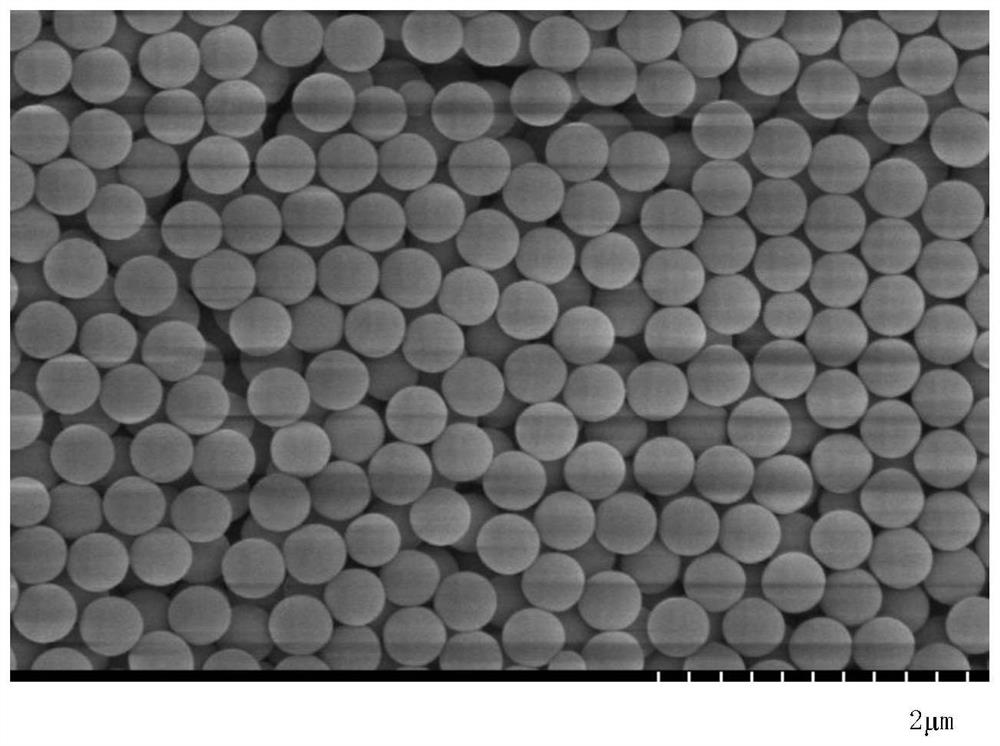

Preparation method of monodisperse aperture-adjustable full-porous silicon dioxide chromatographic microspheres

A silicon dioxide, monodisperse technology, applied in the direction of silicon dioxide, silicon oxide, chemical instruments and methods, etc., can solve problems such as difficulty in obtaining spherical silica gel stationary phase, affecting separation effect, difficult pore size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]In a 25mL single-necked flask, add 1.8mL ammonia water, 3.25mL EtOH, 4.95mL water, 0.153g dodecylamine and 0.153g dodecylamine polyoxyethylene ether, stir and mix at a stirring speed of 1100rpm, then add the previously mixed 0.9mL TEOS and 9.1mL EtOH were quickly poured into the reaction flask. After stirring and reacting at a stirring speed of 1100rpm for 1min, lower the rotating speed to 360rpm, and stir and react at room temperature for 2h; filter the reaction solution, wash with water, wash with alcohol, and dry, take 50mg of washed seed microspheres, and add them to 330mL In the reaction solution, wherein the concentration of ammonia water is 3.5mol / L, the concentration of water is 10mol / L, and the rest are all ethanol, and 3.212g dodecylamine and 3.212g dodecylamine polyoxyethylene ether are added therein, and the stirring speed is 1500rpm Mix the reactants evenly, and slowly inject 100mL of 0.03mol / L TEOS solution (solvent is ethanol) into the reaction system for ...

Embodiment 2

[0032] In a 25mL single-necked flask, add 1.8mL ammonia water, 1.00mL EtOH, 7.10mL water, 0.153g dodecylamine and 0.153g dodecylamine polyoxyethylene ether, stir and mix at a stirring speed of 1100rpm, then add the previously mixed 0.9mL TEOS and 9.1mL EtOH were quickly poured into the reaction flask. After stirring and reacting for 1min at a stirring speed of 1100rpm, reduce the rotating speed to 360rpm, and stir and react at room temperature for 2h, filter the reaction solution, wash with water, wash with alcohol, and dry, take 50mg of the washed seed microspheres and add them to 330mL In the reaction solution, wherein the concentration of ammonia water is 3.5mol / L, the concentration of water is 10mol / L, and the rest are all ethanol, and 3.212g dodecylamine and 3.212g dodecylamine polyoxyethylene ether are added therein, and the stirring speed is 1500rpm Mix the reactants evenly, and slowly inject 100mL of 0.03mol / L TEOS solution (solvent is ethanol) into the reaction system...

Embodiment 3

[0034] Similar to Example 1, the difference is that in the template-guided seed growth step, the volume ratio of ethanol / water in the solvent system of water and ethanol is 1:1, and the template agent adopts polyethylene oxide-polypropylene oxide- Polyethylene oxide triblock copolymer. In the seed growing step, the concentration of TEOS in the TEOS solution is 0.03 mol / L, the concentration of the ammonia water is 1 mol / L; the stirring speed of high-speed stirring is 1800 rpm. The temperature of hydrothermal hole expansion is 100°C, and the time of hydrothermal hole expansion can be 96h. The temperature of constant temperature calcination is 500° C. for 7 hours, and the atmosphere is oxygen. The temperature of lye reaming is 90℃, and the time of lye reaming can be 60h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com