Geopolymer molecular sieve, preparation method and application

A polymer and molecular sieve technology, which is applied in the direction of molecular sieve compounds, molecular sieve catalysts, molecular sieves and base exchange compounds, etc., can solve the problem of single diffusion limitation of sieve structure, achieve the effect of fluffy structure and improved capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060]In the present embodiment, the gasified slag, a silica sol, and alkaline excitation agent is raw, and the content of the gasified slag is 17.24%, the silica sol content is 34.8%, and the content of the basic excitation agent is 48.28. %, The amount of the gasified slag, silica sol with the alkaline excitation agent is 100%. The coal gasification slag is mechanically polished, and the water-soluble impurities are passed through mechanically polished, and the water-soluble impurity is washed, and the cooling is baked; the mass fraction of the pretreated gasifier slag and the NaOH will be in normal temperature. The mixture was mixed and mixed, and the reaction was obtained at 120 ° C to 150 ° C, and the reaction was obtained after the reaction was obtained; the material obtained by the material obtained by the substrate was separated, and the silica sol were added to the isolated filtrate, mixed uniform and stirred to the stick. The thickness appears; the resulting material is po...

Embodiment 2

[0065]The present embodiment is different from that of the first embodiment: the crystallization time is 10 h, the other test parameters and the preparation step are the same as in Example 1, and finally obtain a gasified slag base polymer molecular sieve.

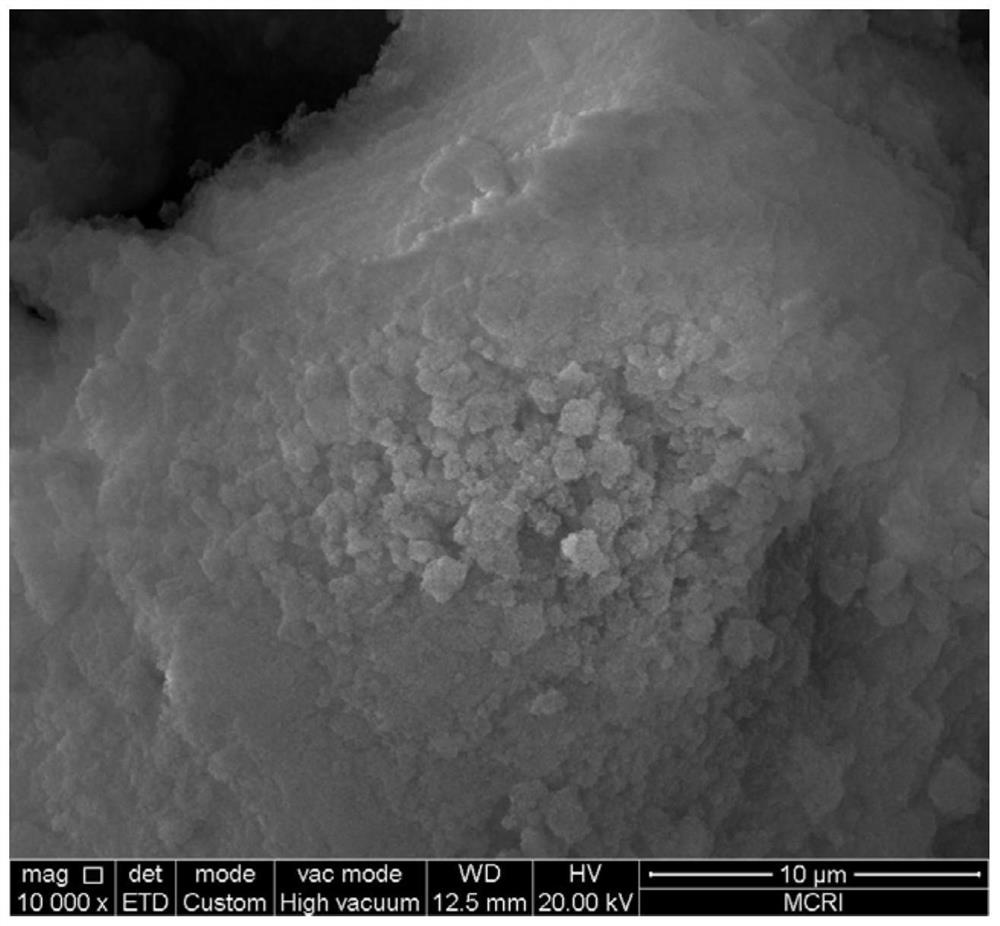

[0066]Such asFigure 4 As shown, the gasification slag base polymer molecular sieve prepared in Example 2 is irregular particulate shape, and the surface distribution has a relatively intensive and size of different sizes. The pore distribution of the molecular sieve is more dense compared to Example 1.

[0067]Analysis of results:

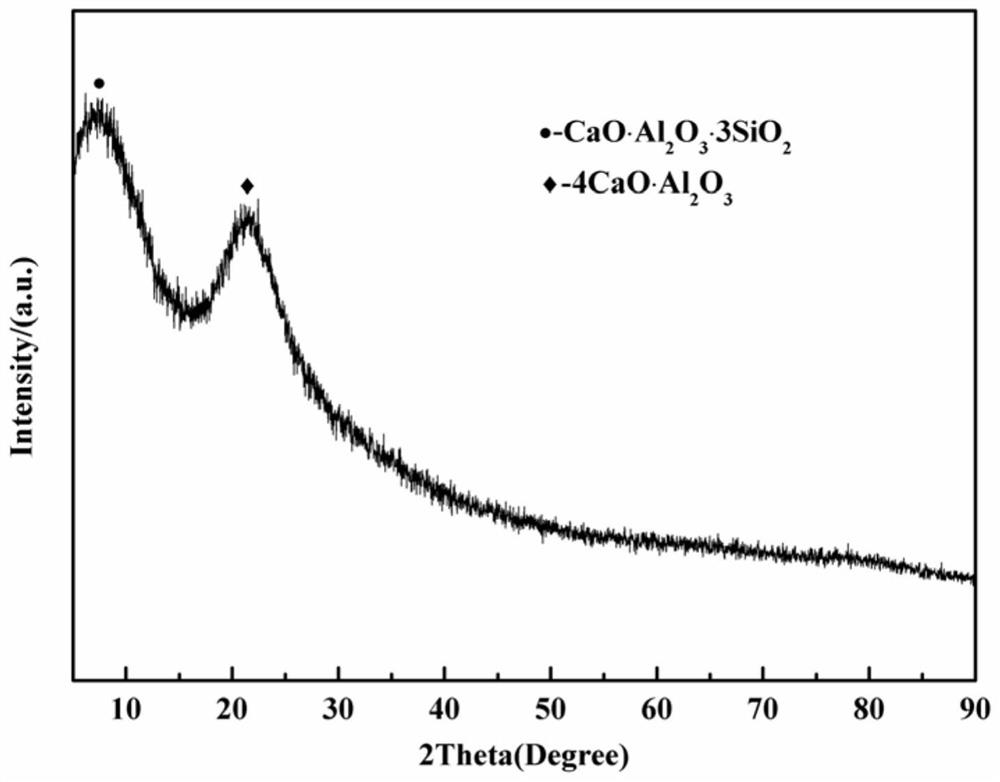

[0068]Such asimage 3 As shown, it is detected that the ingredients contained in the gasified slag base polymer molecular sieve contained in the present embodiment include aluminum silicate calcium CaO · Al2O3· 3Sio2, Calcium aluminate Cao · Al2O3.

Embodiment 3

[0070]In this embodiment, the first embodiment is that the crystallization time is 12 h, the other test parameters and the preparation step are the same as in Example 1, and finally obtain a gasified slag base polymer molecular sieve.

[0071]Such asFigure 6 As shown, the gasified slag base polymer molecular sieve surface prepared in Example 3 is relatively flat, and the surface particle portion is irregular four-sided shape, and the part is a scales; the increase in magnification can also be observed. The pore distribution of the molecular sieve is more dense compared to Example 1.

[0072]Analysis of results:

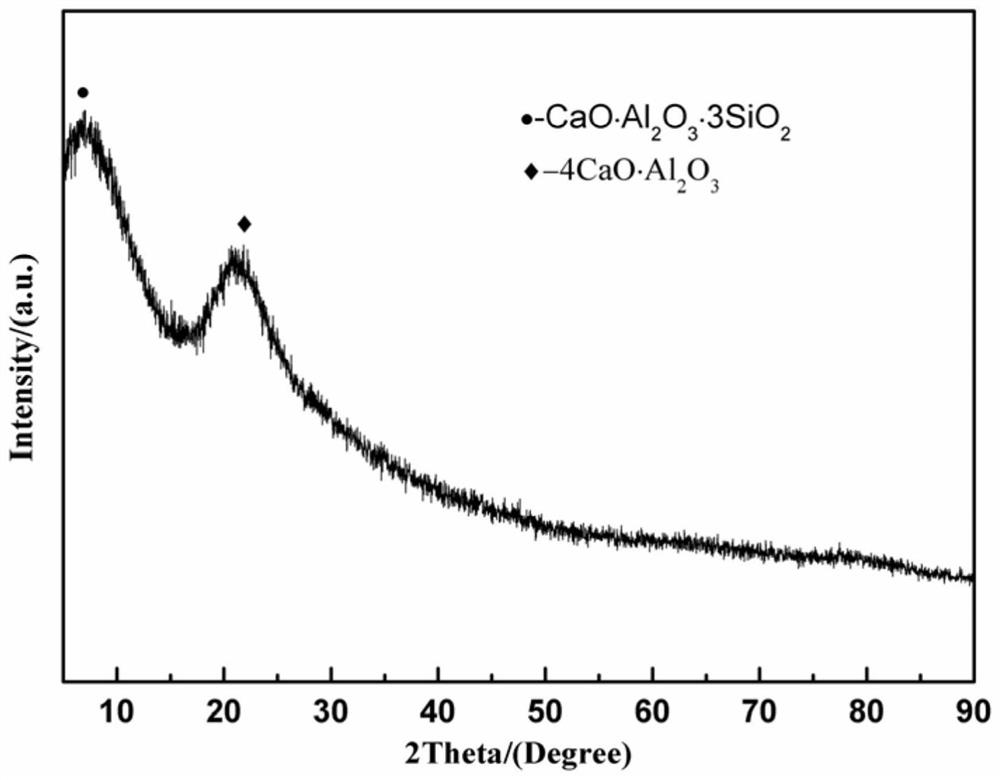

[0073]Such asFigure 5 As shown, it is detected that the ingredients contained in the gasified slag base polymer molecular sieve contained in the present embodiment include aluminum silicate calcium CaO · Al2O3· 3Sio2, Calcium aluminate Cao · Al2O3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com