Modularized multi-stage-area mineralization metallurgy system and treatment method

A modular and treatment area technology, which is applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve the limitations of deep separation and enrichment of components to be separated, large vertical area of equipment, Difficult to meet the requirements of industrial production and other issues, to achieve the effect of small footprint, convenient equipment, and high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

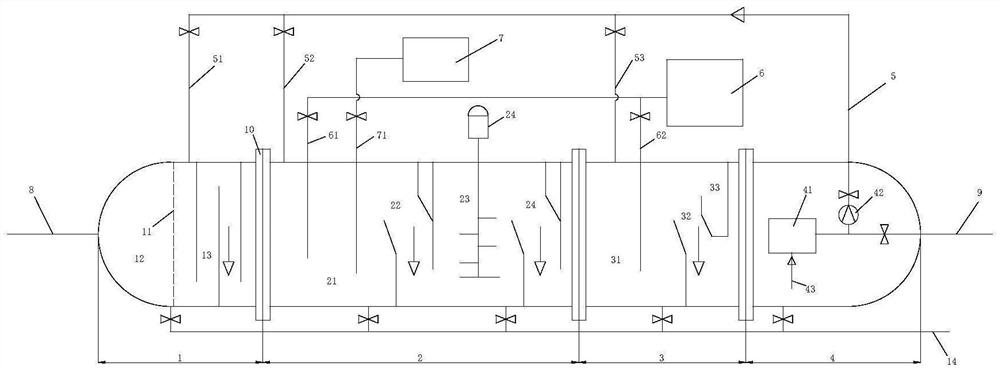

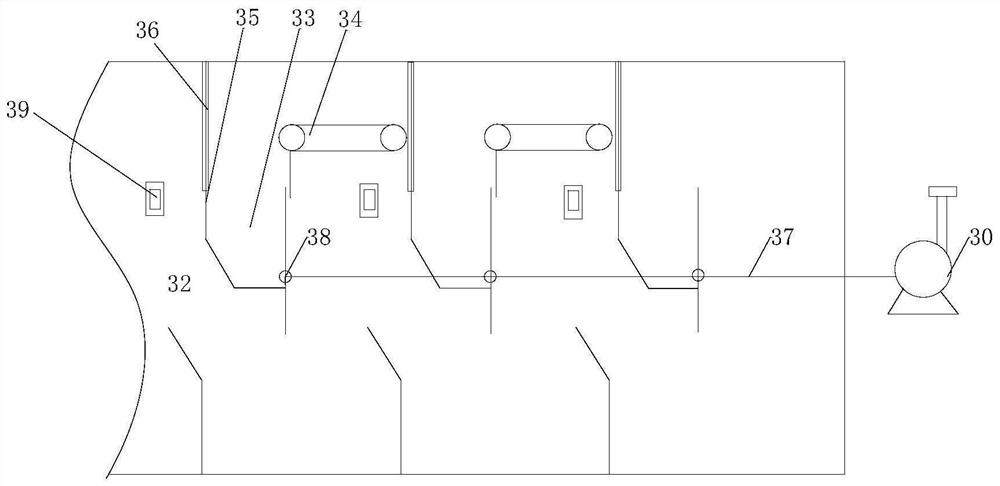

[0059] Mineralization metallurgical equipment removes copper, lead, and zinc from industrial wastewater. The process is as follows:

[0060] (1) The industrial wastewater of a lead-zinc smelter contains 200mg / L copper, 280mg / L lead, and 153mg / L zinc. The industrial wastewater is transported to the mineralization and metallurgical equipment system by a multi-phase flow dissolved air pump, and filtered through a 325-mesh filter. After net sedimentation and filtration, it enters the chemical mineralization area, and adds humic acid-based complexing and chelating agents to the industrial wastewater through the chemical filling system. The amount of complexing and chelating agents is 1.5 times the theoretical amount of complete complexation of metal ions, resulting in hydrophobic Precipitate floc particles, floc particles at 10mg / L Fe 3+ growing under the action of destabilizing flocculants, Fe 3+ The addition amount is 0.2%, and finally it is mechanically stirred at 300r / min for ...

Embodiment 2

[0065] Mineralization metallurgical equipment separates dissolved tungsten and molybdenum, the process is as follows:

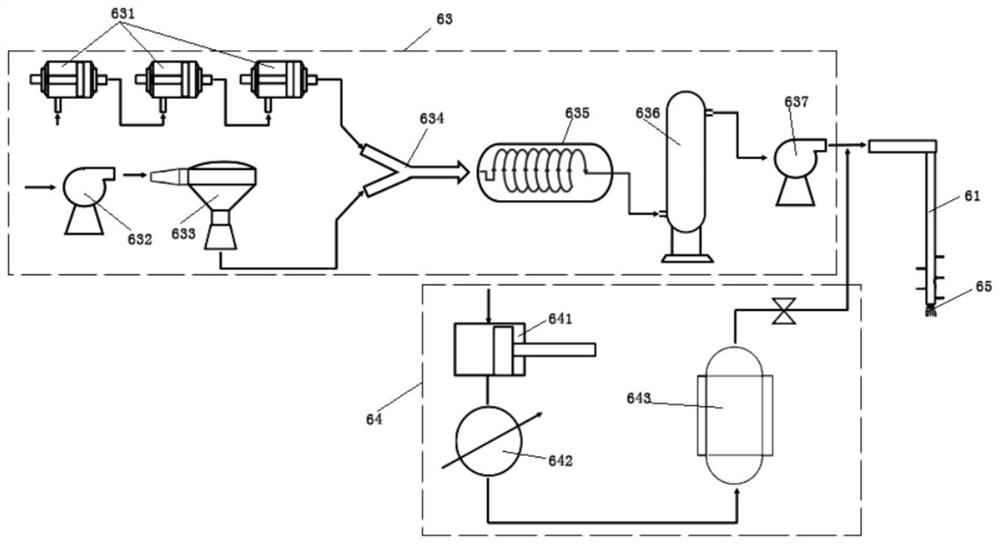

[0066] (1) A certain tungsten ore leach solution contains Mo 1.73g / L, WO 3 200 g / L, the tungsten and molybdenum leaching solution is transported to the mineralization metallurgical equipment system with a multiphase flow dissolved air pump at a flow rate of 20L / min, and after being filtered by a 325-mesh filter, it enters the chemical mineralization area and passes through the chemical filling system. Add ammonium sulfide and alkyltrimethylammonium chloride with a content of 1.5 times the molybdenum content to the leaching solution to produce a hydrophobic molybdenum-containing complex, and mechanically stir at 300r / min for 30min to ensure that the molybdenum in the solution can form a uniform and stable molybdenum-containing complex. Complexes.

[0067] (2) The molybdenum-containing complex enters the bubble mineralization zone, continuously collides with 2...

Embodiment 3

[0071] Mineralization metallurgical equipment flocculation flotation micro-fine molybdenite, the process is as follows:

[0072] (1) A molybdenite sample (Mo grade about 0.09%) contains a large amount of gangue minerals quartz and kaolinite, and the molybdenite particles with a particle size of less than 5 μm account for more than 80%. The mineral suspension is transported to the mineralization and metallurgical equipment system, after sedimentation and filtration, and after hydraulic classification, the suspension with a particle size of less than 200 meshes enters the chemical mineralization area, and a content of 0.5 is added to the suspension through the chemical filling system. % humic acid-based selective flocculant to produce hydrophobic flocculation particles, which are continuously grown under the action of 0.2% polyacrylamide destabilizing flocculant, and mechanically stirred at 300r / min for 30min.

[0073] (2) Particles with a particle size of 30-60 μm enter the bub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com