Polycation side chain type anion exchange membrane prepared based on soft template method and preparation method of polycation side chain type anion exchange membrane

An anion exchange membrane and polycation technology, applied in the field of polycation side chain type anion exchange membrane and its preparation, can solve the problems of poor selectivity, low ion flux, etc., to promote formation, increase ion flux, and improve selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of brominated polyphenylene ether

[0042] Dissolve 12g of polyphenylene ether in 100mL of chlorinated benzene, and add a mixed reagent of N-bromosuccinimide and azobisisobutyronitrile at a molar ratio of 10:1, wherein N-bromosuccinimide 5.34g. The reaction was carried out at 120° C. for 4 hours. The reactant was poured into 1000 mL of absolute ethanol for precipitation, washed with absolute ethanol until the supernatant was colorless, and then vacuum-dried at 40° C. for 48 hours to obtain a polymer: brominated polyphenylene ether. The degree of bromination of the brominated polyphenylene ether is 10%.

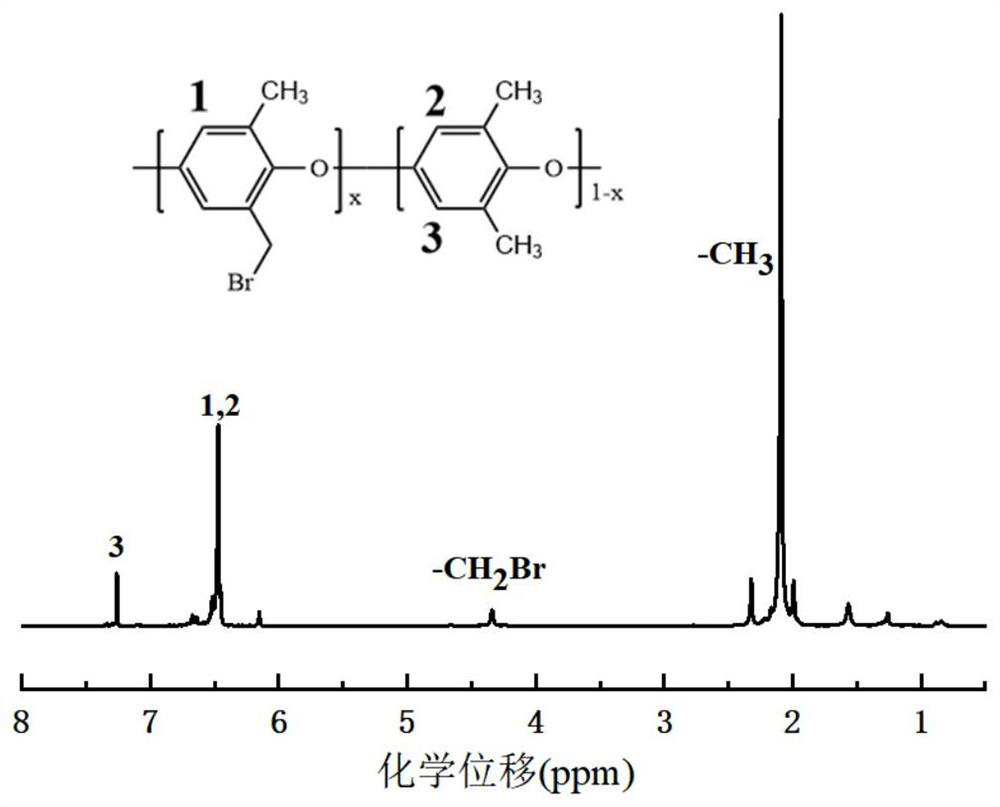

[0043] figure 1 H for the brominated polyphenylene ether prepared in Example 1 1 NMR spectrum, wherein the peak generated at 4.3ppm is the peak of bromomethyl group, which proves the successful preparation of brominated polyphenylene ether.

[0044] (2) Preparation of ionizing reagents

[0045] First, 37.9 mL of 1,6-dibromohexane was dissolved in ...

Embodiment 2

[0055] (1) Preparation of brominated polyphenylene ether

[0056] Dissolve 12g of polyphenylene ether in 100mL of chlorinated benzene, and add a mixed reagent of N-bromosuccinimide and azobisisobutyronitrile at a molar ratio of 12:1, wherein N-bromosuccinimide 6.23 g. The reaction was carried out at 125°C for 3.5 hours. The reactant was poured into 1000 mL of methanol for precipitation, washed with methanol until the supernatant was colorless, and then vacuum-dried at 40° C. for 48 hours to obtain a polymer: brominated polyphenylene ether. The degree of bromination of the brominated polyphenylene ether is 10%.

[0057] (2) Preparation of ionizing reagents

[0058] First, dissolve 37.9mL of 1,6-dibromohexane in 90mL of tetrahydrofuran to form a co-solution, pass 59.1mL of trimethylamine solution into the co-melt solution 1 at 80°C, react at 30°C for 18 hours and then vacuum After filtration, it was washed with tetrahydrofuran, and vacuum-dried at 40°C for 48 hours to obtain...

Embodiment 3

[0066] (1) Preparation of brominated polyphenylene ether

[0067] Dissolve 12g of polyphenylene ether in 100mL of chlorinated benzene, and add a mixed reagent of N-bromosuccinimide and azobisisobutyronitrile at a molar ratio of 15:1, wherein N-bromosuccinimide 7.12 g. The reaction was carried out at 130° C. for 3 hours. The reactant was poured into 1000 mL of absolute ethanol for precipitation, washed with absolute ethanol until the supernatant was colorless, and then vacuum-dried at 40° C. for 48 hours to obtain a polymer: brominated polyphenylene ether. The degree of bromination of the brominated polyphenylene ether is 10%.

[0068] (2) Preparation of ionizing reagents

[0069] First, dissolve 37.9mL of 1,6-dibromohexane in 90mL of tetrahydrofuran to form a co-solution, pass 52.6mL of trimethylamine solution into the co-melt 1 at 80°C, react at 35°C for 14 hours, and then vacuum After filtration, it was washed with tetrahydrofuran, and vacuum-dried at 40°C for 48 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com