A photosensitive color-changing pencil paint and a process for producing photosensitive color-changing pencils using the same

A photochromic, pencil technology, applied in non-moving pencils, multi-color effect paints, devices for coating liquids on surfaces, etc. performance, good photochromic effect, good light fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

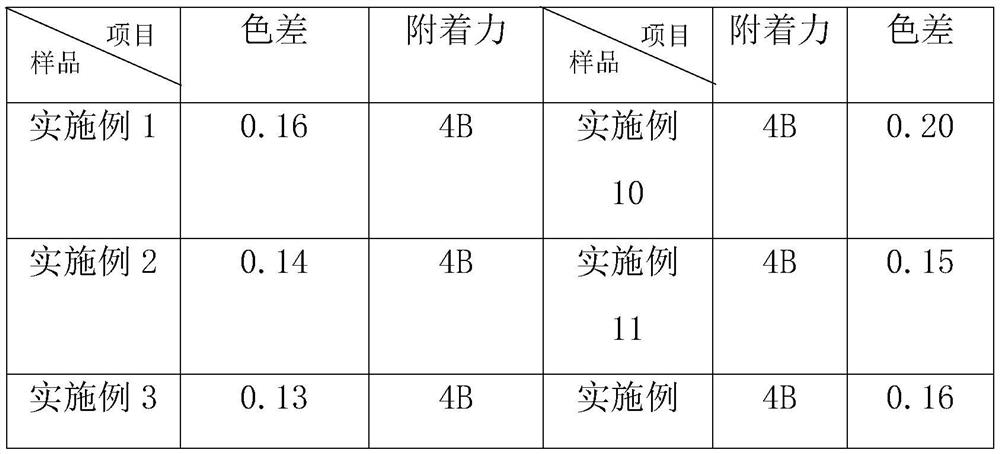

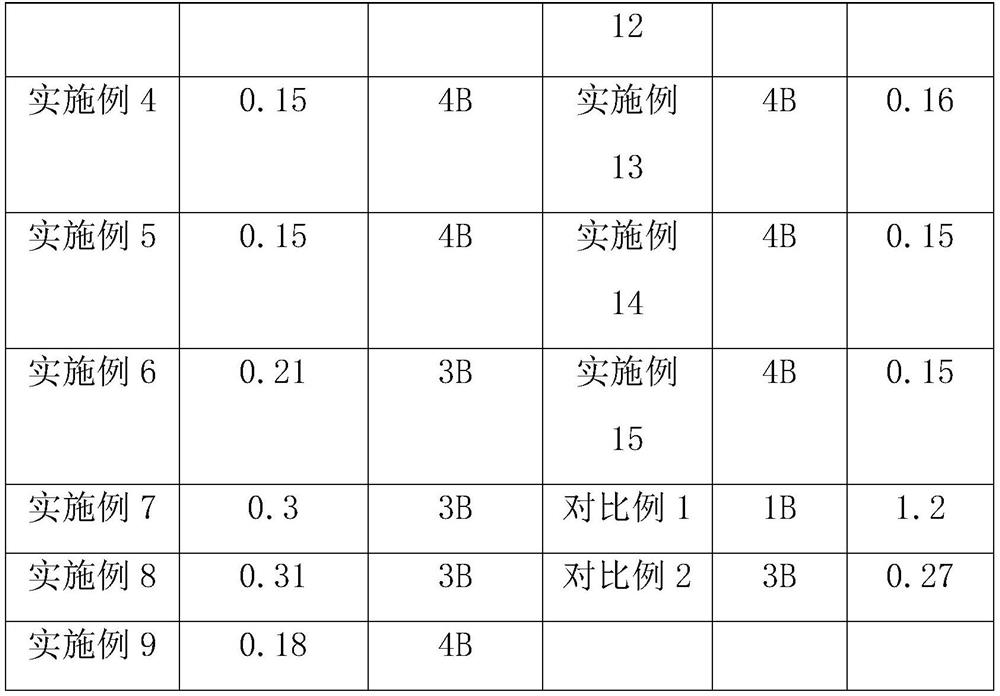

Examples

preparation example 1

[0086] (1) under the protection of nitrogen atmosphere, with mass parts (1 part / kg), the n-heptanoic acid of 108 parts, the propylene glycol of 122 parts, the xylene of 1.2 parts of catalyst and 191 parts are added in the reaction kettle, then rise slowly High temperature to 180°C, continuous reaction for 13 hours;

[0087] (2) The by-product water generated in the reaction process can be removed by a water separator; after the reaction is finished, xylene and unreacted small molecule raw materials are removed by vacuum distillation; finally, the hydroxyl-terminated poly(o- Phthaloyl-ethylene glycol) ester;

[0088] (3) Next, under the protection of a nitrogen atmosphere, add xylene into the reactor, and gradually raise the temperature to 50°C; take 136 parts of hydroxyl-terminated poly(phthaloyl-ethylene glycol) ester and add it to the reactor , keep warm at 50°C for 30 minutes; then slowly add 136 parts of toluene diisocyanate into the xylene solution, and keep it warm for ...

preparation example 2

[0092] (1) under nitrogen atmosphere protection, with mass parts (1 part / kg), the n-heptanoic acid of 122 parts, the propylene glycol of 146 parts, the xylene of 1.4 parts of catalyzer and 217 parts are added in the reactor, then rise slowly High temperature to 180°C, continuous reaction for 13 hours;

[0093] (2) The by-product water generated in the reaction process can be removed by a water separator; after the reaction is finished, xylene and unreacted small molecule raw materials are removed by vacuum distillation; finally, the hydroxyl-terminated poly(o- Phthaloyl-ethylene glycol) ester;

[0094] (3) Next, under the protection of a nitrogen atmosphere, add xylene into the reactor, and gradually raise the temperature to 50°C; take 154 parts of hydroxyl-terminated poly(phthaloyl-ethylene glycol) ester and add it to the reactor , keep warm at 50°C for 30 minutes; then slowly add 154 parts of toluene diisocyanate into the xylene solution, and keep it warm for 2 hours;

[0...

preparation example 3

[0098] (1) under nitrogen atmosphere protection, with mass parts (1 part / kg), the n-heptanoic acid of 115 parts, the propylene glycol of 131 parts, the xylene of 1.3 parts of catalyzer and 204 parts are added in the reactor, then rise slowly High temperature to 180°C, continuous reaction for 13 hours;

[0099] (2) The by-product water generated in the reaction process can be removed by a water separator; after the reaction is finished, xylene and unreacted small molecule raw materials are removed by vacuum distillation; finally, the hydroxyl-terminated poly(o- Phthaloyl-ethylene glycol) ester.

[0100] (3) Next, under the protection of a nitrogen atmosphere, add xylene into the reaction kettle, and gradually raise the temperature to 50°C; take 145 parts of hydroxyl-terminated poly(phthaloyl-ethylene glycol) ester and add it to the reaction kettle , keep warm at 50°C for 30min; then slowly add 145 parts of toluene diisocyanate into the xylene solution, and keep warm for 2h.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com