A method for constructing a photoelectrochemical sensor to detect 5-hydroxymethylcytosine

A hydroxymethylcytosine, photoelectrochemical technology, applied in the field of photoelectrochemical analysis, can solve the problems of being too time-consuming, expensive, and not attracting enough attention, and achieve the effects of easy operation, low cost, and improved hole transfer rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

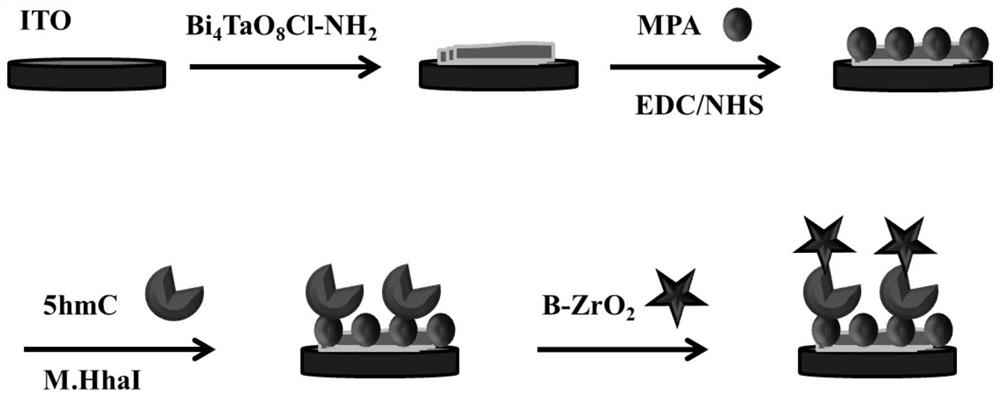

Method used

Image

Examples

preparation example Construction

[0053] (2) Black ZrO 2 Preparation: 0.5-2g ZrO 2 Grinding and mixing with 0.01-1g of sodium borohydride, calcining at 300-700°C for 0.5-3h in a nitrogen atmosphere, washing the obtained black solid powder with deionized water, and drying in vacuum. Finally, the product is ground and collected for later use.

[0054] (3) Aminated perovskite Bi 4 TaO 8 Cl-NH 2 Preparation of the dispersion: weigh 1-20 mg of aminated perovskite Bi 4 TaO 8 Cl-NH 2 , added to 3-10mL deionized water, and ultrasonically dispersed for 1-3 hours.

[0055] (4) Black ZrO 2 Preparation of dispersion: weigh 1-20mg black ZrO 2 , added to 1-10mL deionized water, and ultrasonically dispersed for 1-3 hours.

[0056] (5) ITO electrode pretreatment: cut the ITO conductive glass into 5×1cm 2 For small pieces, ultrasonically clean them with acetone for 30-60 minutes, and then ultrasonically clean them with NaOH (0.01-1M molar concentration) ethanol / water (volume ratio of ethanol to water: 1:1 to 1:3) mix...

Embodiment 1

[0076] Example 1: Aminated perovskite Bi 4 TaO 8 Cl-NH 2 preparation of

[0077] Weigh 1.7g Bi 2 o 3 ,0.5g Ta 2 o 5 , 0.6g BiOCl, 1.4g NaCl and 1.8g KCl powders were ground and mixed, and calcined at 700°C for 5 hours in an air atmosphere, and the calcined solid was taken out, and after grinding, it was centrifuged and washed with deionized water at 10,000rpm to collect the precipitate, and stored at 60°C Vacuum drying yields yellow perovskite Bi 4 TaO 8 Cl. Bi 4 TaO 8 The Cl powder was ultrasonically dispersed in a mixed solution of ethanol and water (ethanol:water ratio of 1:1), and 3 mL of APTES solution was added under constant stirring, and heated to 70° C. for reflux reaction for 7 h. After cooling to room temperature, the precipitate was collected by centrifugation, and then the precipitate was sequentially washed with absolute ethanol and water at a speed of 10000 rpm, and the final product was vacuum-dried at 60°C and collected by grinding.

Embodiment 2

[0078] Example 2: Black ZrO 2 preparation of

[0079] White 1g ZrO 2 Grinding and mixing with 0.5g of sodium borohydride for 30min, calcining at 650°C for 3h under a nitrogen atmosphere to obtain a black solid powder, washing with deionized water, and finally the product was vacuum-dried and collected by grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com