Negative electrode and lithium secondary battery comprising same

A negative electrode and negative electrode active material technology, applied in the direction of secondary batteries, lithium batteries, negative electrodes, etc., can solve the problems of solid-electrolyte interphase instability, poor cycle performance, phosphorus use restrictions, etc., to achieve excellent fast charging characteristics and Effects of lifetime, high energy density, and excellent Li+ conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

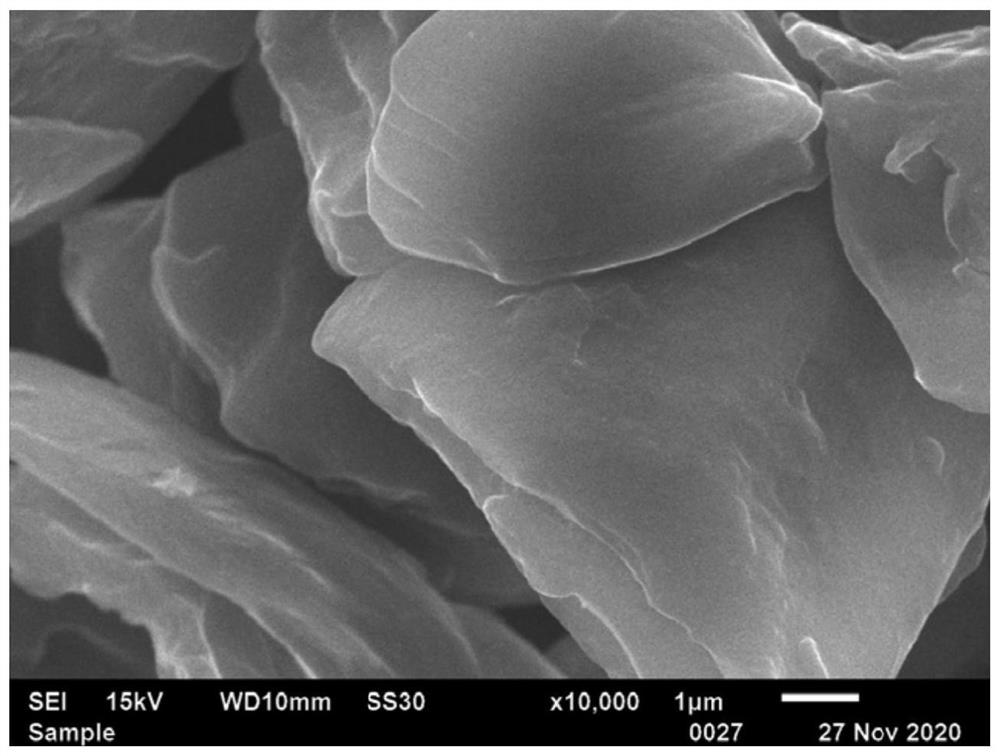

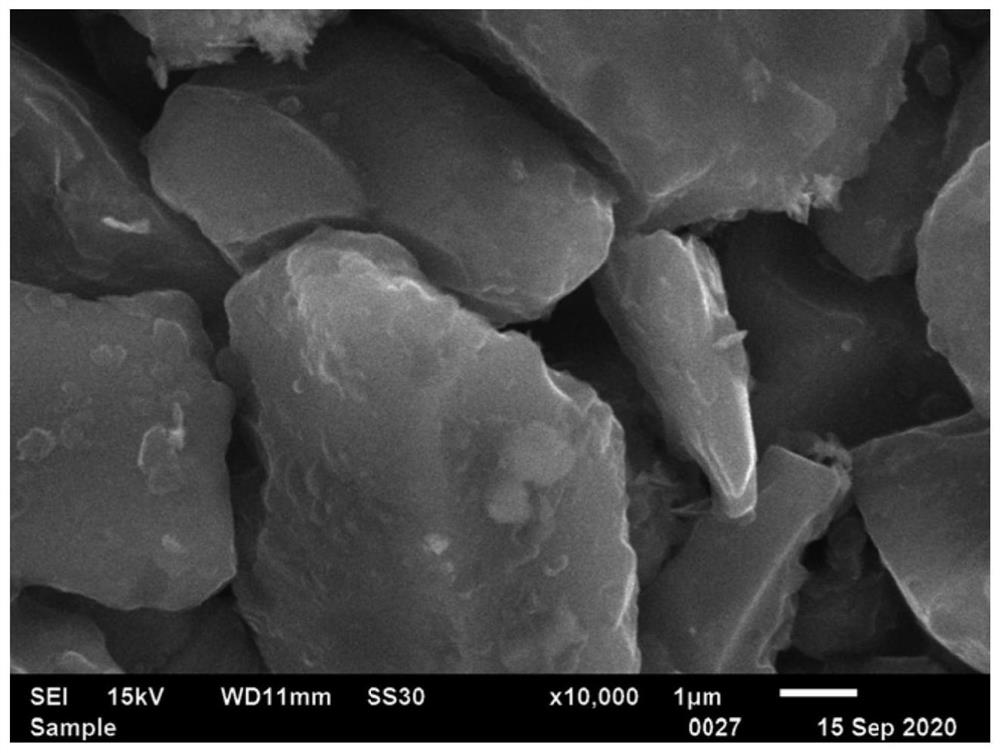

[0038] The preparation method of the phosphorus-carbon composite with an organic coating on the surface: (1) A certain proportion of bulk phosphorus and carbon mixture is ball-milled with a planetary ball mill, and the revolution speed is 50-300 / min. The rotation speed is 100-500r / min, and the ball milling time is 8-48h to form a phosphorus-carbon compound; (2) In a vacuum glove box, add the organic matter that forms the organic coating into the ball mill tank containing the phosphorus-carbon compound, and ball mill again , the revolution speed is 10-100r / min, the rotation is 50-200r / min, and the ball milling time is 2-6h, forming a phosphorus-carbon composite with an organic coating on the surface.

[0039] In addition, the mass ratio of the first negative electrode active material layer to the second negative electrode active material layer is less than or equal to 1:1, that is, the layer density of the second negative electrode active material is higher than the first negati...

Embodiment 1

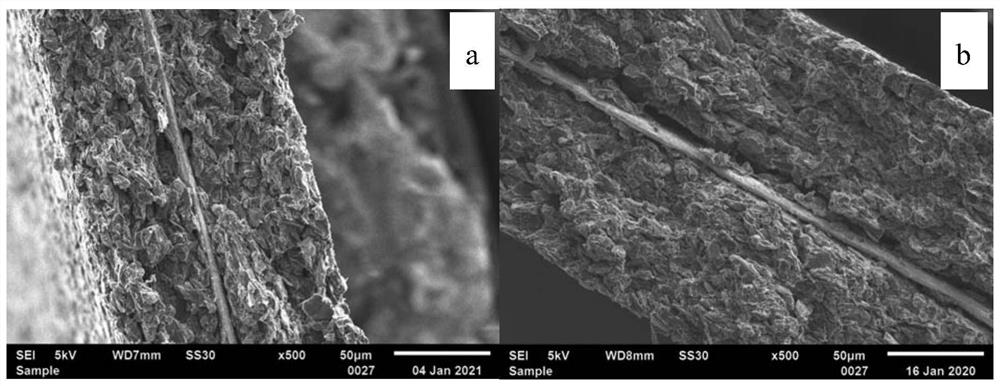

[0056] The mixture of artificial graphite and natural graphite as the weight ratio of negative active material of 80:20, the SBR as binder, the CMC as thickener and the carbon black as conductive material are 95.4:2.3 by weight: 1.3:1.0 in a weight ratio, and water was added thereto as a solvent to prepare the first negative electrode slurry. The mixture of artificial graphite and black phosphorus as the weight ratio of the negative electrode active material of 20:80, the SBR as the binding agent, the CMC as the thickener and the carbon black as the conductive material are 95.5:2.3 by weight: Mixed at a weight ratio of 1.3:1.0, wherein based on the weight of the phosphorus-carbon composite, the surface contained 10% polyaniline, and water was added thereto as a solvent to prepare the second negative electrode slurry. The first negative electrode slurry and the second negative electrode slurry were applied to a copper foil having a thickness of 8 μm at a weight ratio of 1:1. D...

Embodiment 2

[0060] Embodiment 2: Changing the ratio of negative electrode active material black phosphorus and graphite in the second negative electrode active material layer

[0061] The negative electrode was prepared in the same manner as in Example 1, except that a mixture of artificial graphite and azurite phosphorus with a weight ratio of 10:90 was used as the negative active material of the second negative electrode slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com