Polyimide film cold-pressed composite busbar for automobile capacitor and preparation method of polyimide film cold-pressed composite busbar

A polyimide film, composite busbar technology, applied in multiple fixed capacitors, vehicle connectors, components of fixed capacitors, etc., can solve the problem of insufficient high voltage resistance level, insufficient high temperature resistance level, and insufficient wear resistance. and other problems, to achieve the effect of wide applicable temperature range, strong mechanical properties and high withstand voltage level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

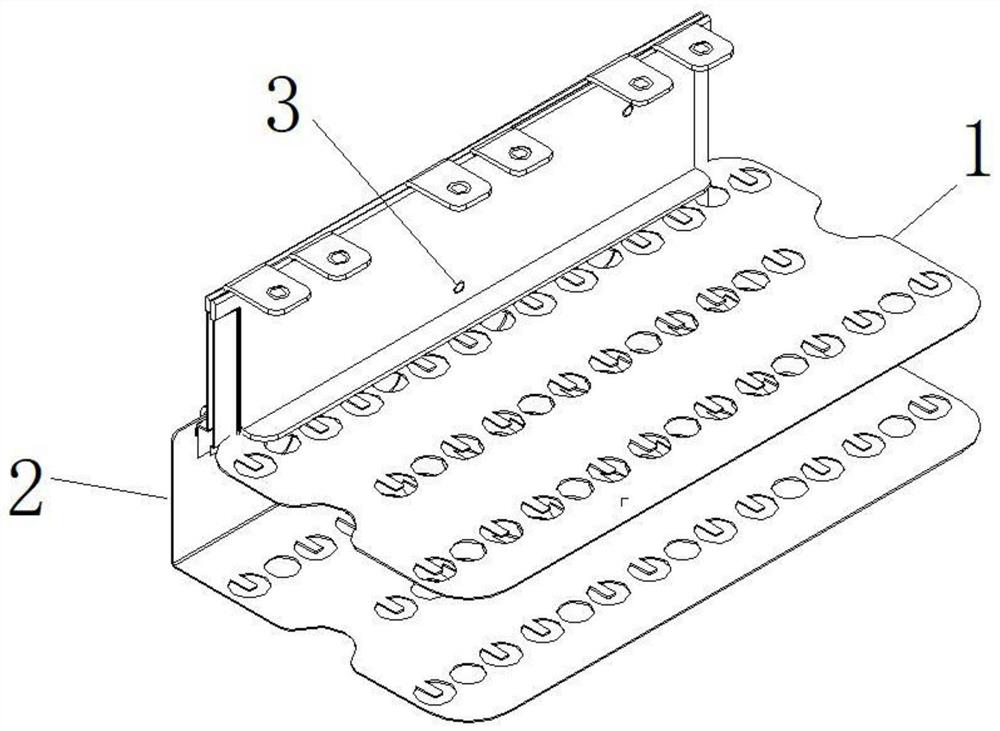

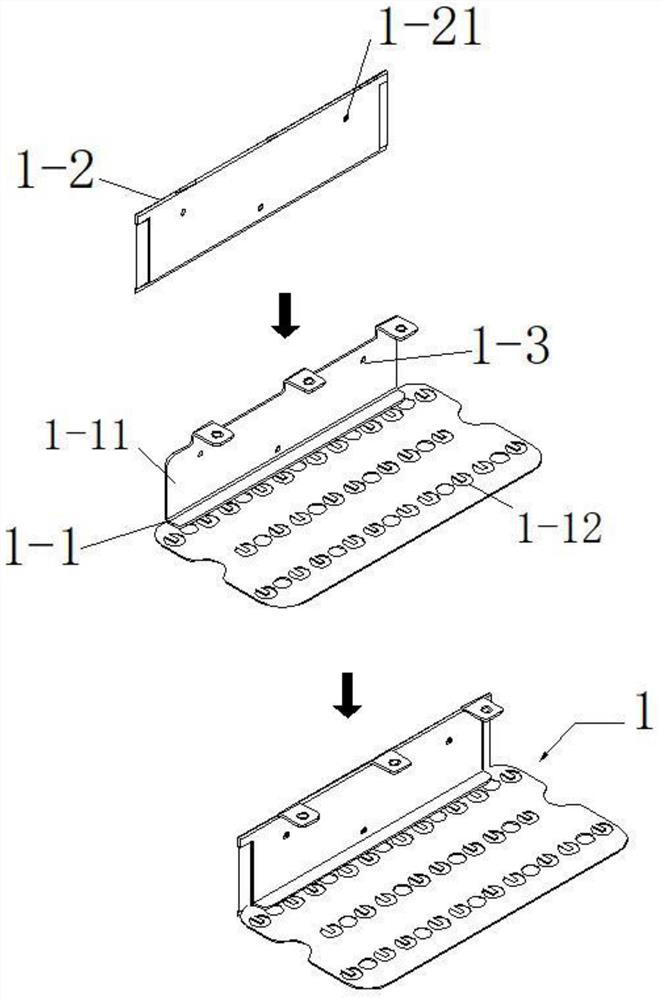

[0043] Such as figure 1 As shown, it is a polyimide film cold-pressed composite busbar for automobile capacitors provided by the present invention. The composite busbar includes an upper busbar unit 1 and a lower busbar unit 2, such as figure 2 As shown, the upper busbar unit 1 includes an L-shaped upper busbar 1-1 and an upper busbar insulation film 1-2, and the L-shaped upper busbar 1-1 includes an upper busbar vertical plate 1-11 and an upper busbar vertical plate 1-11. The bus drain plate 1-12, and the upper bus bar insulation film 1-2 are attached to the inner side of the upper bus bar vertical plate 1-11 by cold-sticking and cold-pressing process of one-sided or double-sided coating of polyethylene adhesive;

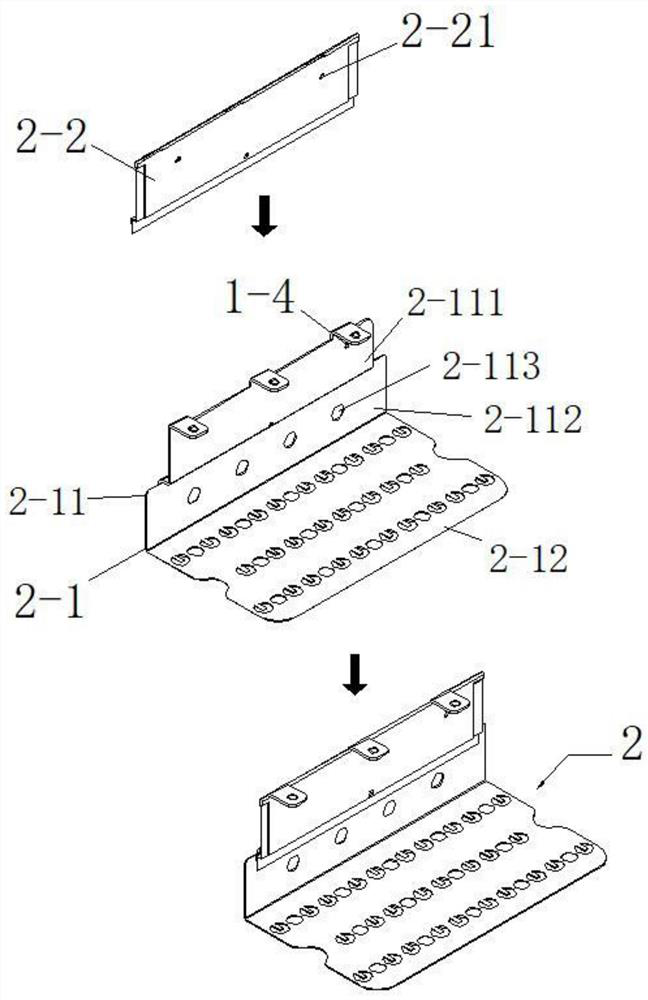

[0044] Such as image 3As shown, the lower busbar unit 2 includes an L-shaped lower busbar 2-1 and a lower busbar insulation film 2-2, and the L-shaped lower busbar 2-1 includes a lower busbar vertical plate 2-11 and a lower busbar vertical plate 2-11. The bus d...

Embodiment 2

[0054] This embodiment provides the method for preparing the polyimide film cold-pressed composite busbar for automobile capacitors in Embodiment 1, including the following steps:

[0055] 1) T2Y2 red copper plate with a thickness of 1.5mm is used to make L-shaped upper busbar 1-1 and L-shaped lower busbar 2-1;

[0056] 2) Use PPS-50GF material mold injection molding or 3D printing to form a flying saucer-shaped positioning pin 3;

[0057] 3) Coat one or both sides of the upper busbar insulating film 1-2 with polyvinyl alcohol adhesive, and protect it with release paper; and coat one or both sides of the lower busbar insulating film 2-2 Covered with polyvinyl alcohol adhesive and protected by release paper, after mold stamping or laser cutting process, the required pattern is made;

[0058] 4) Place the upper busbar unit 1 and the lower busbar unit 2 on the tooling respectively, and the upper busbar insulation film 1-2 is attached to the upper busbar by cold-sticking and col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com