Preparation method of near-infrared response nanocage and application of near-infrared response nanocage in tumor immune combined therapy

A nanocage and near-infrared technology, applied in the medical field, can solve the problems of limiting the clinical benefits of patients, and achieve the effects of uniform and controllable mesopore size, good biological safety, large specific surface area and pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment provides a method for preparing a near-infrared responsive nanocage, comprising the following steps:

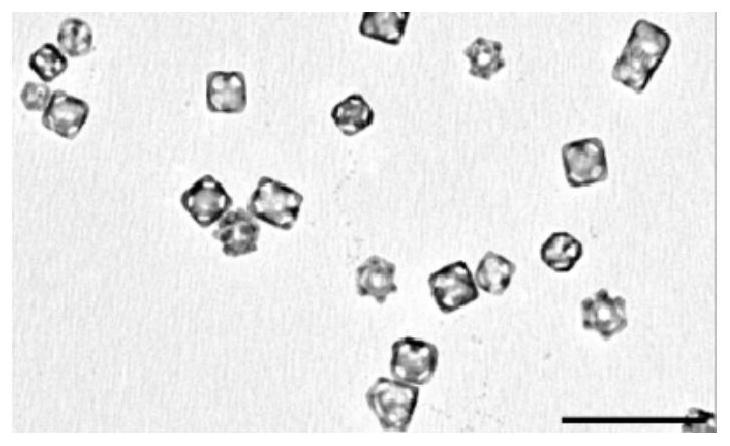

[0064] (1) prepare gold nanocage (AuNC), the method is as follows:

[0065] (S1) 500 μL of Ag nanocubes with a concentration of 3 nmol / L was added to 5 mL of polyvinylpyrrolidone (PVP) ionic water solution with a concentration of 1 mg / mL, and then heated and boiled for 10 min with constant stirring to obtain a mixture a;

[0066] (S2) Take 0.5mmol HAuCl 4 The aqueous solution was added to mixture a at a rate of 45mL / h, and the system was continuously refluxed for 30min until the color became stable, and then cooled to room temperature to obtain mixture b;

[0067] (S3) Centrifuge the mixture b, remove AgCl with saturated NaCl solution, and then wash with deionized water to remove residual PVP and NaCl to obtain AuNC.

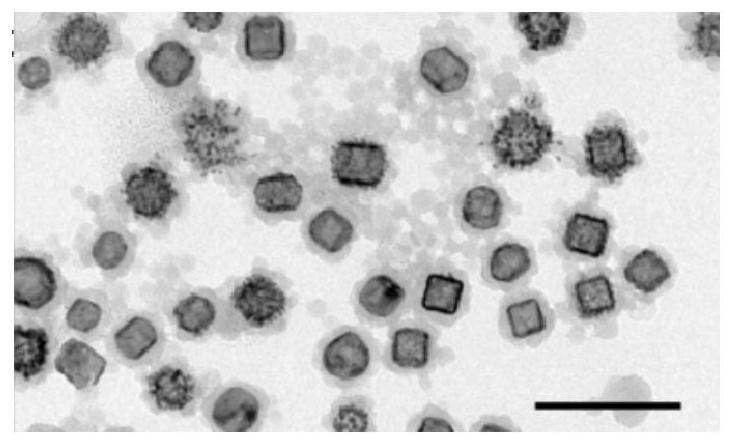

[0068] (II) Preparation of mesoporous silica-coated gold nanocages (AuNC@mSiO 2 ),Methods as below:

[0069] (SS1) Add 4 mL of AuNC ob...

Embodiment 2

[0080] This example provides a method for preparing a near-infrared responsive nanocage, the difference from Example 1 is that in step (S1), the heating and boiling time is 15 minutes; in step (S2), HAuCl 4 The addition rate of the aqueous solution is 50mL / h, and the time for continuous reflux is 40min; in the step (SS1), the reaction is continuously stirred at room temperature for 14h; in the step (SS2), the centrifugation is performed at 7000g for 20min; The washing is alternately washed 4 times with ethanol and deionized water; the stirring reaction is carried out at 55°C for 12h; in step (SSS2), the heating reaction is carried out at 90°C for 8h; the centrifugation is carried out at 7000g Centrifuge for 15 minutes; in step (SSS3), the heating is 75°C, and the reaction time is 5h; in step (SSSS2), the heating is 45°C, and the reaction time is 28h.

[0081] Other operations and raw material consumption are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com