Salt-assisted synthesized multi-morphology carbon nitride as well as preparation method and application thereof

A technology of nitriding carbon light and carbon light, which is applied in the field of photocatalysis, can solve problems affecting photocatalytic activity, etc., and achieve the effects of improved dye degradation efficiency, large specific surface area, and various shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

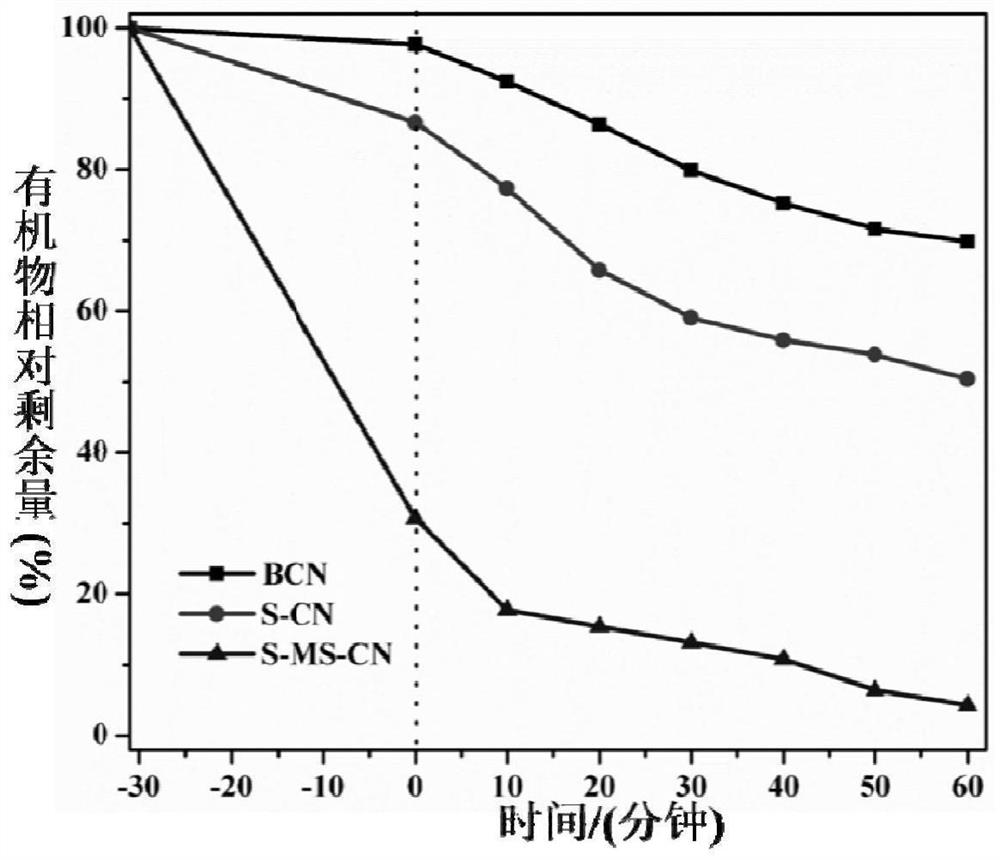

[0045] Preparation of embodiment 1 photocatalyst and performance test thereof

[0046] (1) Preparation of photocatalyst

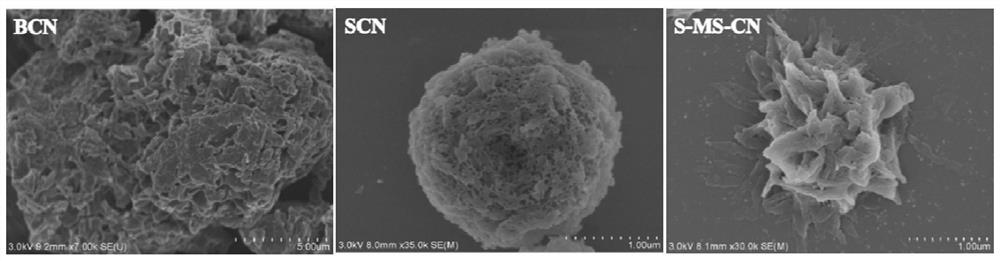

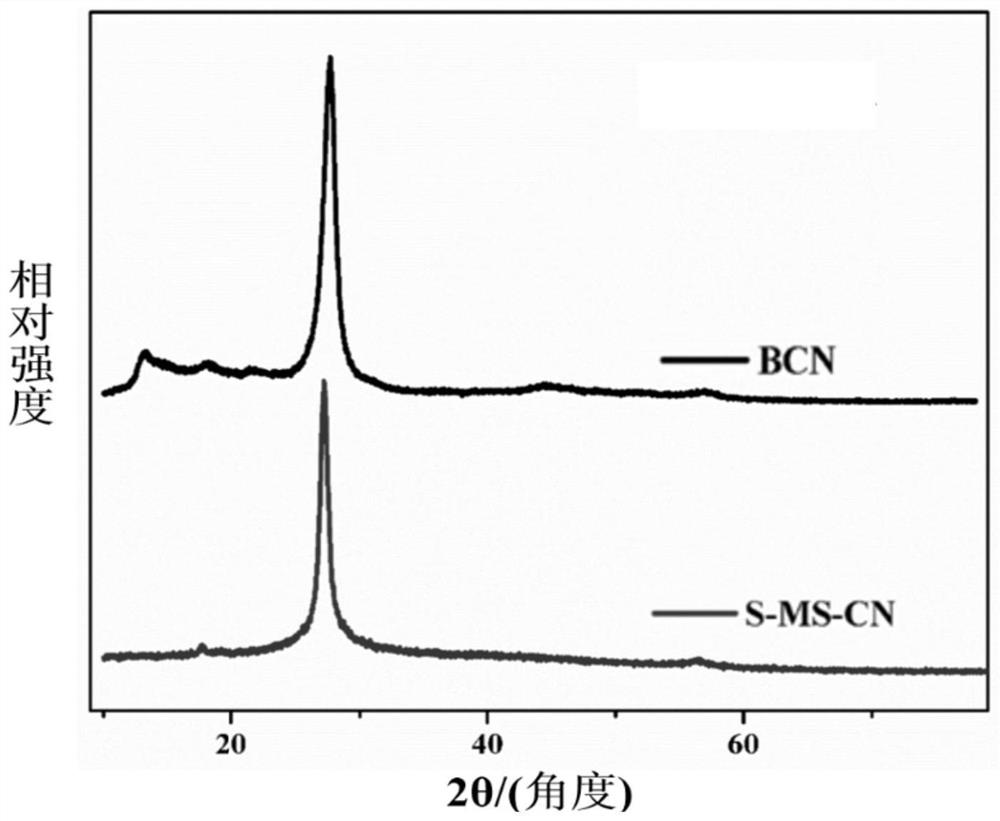

[0047] Catalyst 1: Weigh 10 g of melamine, place it in a muffle furnace for calcination, raise the temperature to 550° C. at a rate of 2.5° C. / min, and keep it warm for 4 hours. After cooling to room temperature, it was ground into powder to make catalyst 1 (named BCN).

[0048] Catalyst 2: Dissolve 0.25g of melamine and 0.25g of cyanuric acid in 20mL of dimethyl sulfoxide (DMSO) solvent respectively, ultrasonicate for 30min, then mix the two solutions to obtain a white suspension, centrifuge, ethanol, After washing with water, disperse in 20 mL of deionized water, quickly freeze with liquid nitrogen, and dry in a freeze dryer for 24 hours. The obtained powder was placed in a muffle furnace and heated to 350°C at a heating rate of 2.5°C / min, and kept for 30min. After cooling to room temperature, catalyst 2 (named S-CN) was prepared.

[0049] Catalyst 3: D...

Embodiment 2

[0059] Embodiment 2 The effect of solvent action on carbon nitride photocatalyst degradation performance

[0060] (1) Carbon nitride photocatalysts synthesized under the action of different solvents

[0061] Dissolve 0.25g melamine and 0.25g cyanuric acid in 20mL DMSO, methanol, ethanol, ethylene glycol, acetone, water or DMF respectively, ultrasonicate for 30min, then mix the two solutions, centrifuge, wash with ethanol and water Net, a solid substance was obtained. Take 0.5g of solid matter and disperse it in 20mL of saline solution (containing 1.2g NaCl and 3.8g KNO 3 ), was quickly frozen with liquid nitrogen, and dried in a freeze dryer for 24 hours. The obtained powder was placed in a muffle furnace and heated to 350°C at a heating rate of 2.5°C / min, and kept for 30min. After cooling to room temperature, wash with deionized water several times to remove residual salt, and dry at 60°C overnight. The corresponding solvents DMSO, methanol, ethanol, ethylene glycol, acet...

Embodiment 3

[0066] Example 3 Effect of Salt Concentration on Carbon Nitride Photocatalyst Degradation Performance

[0067] (1) Carbon nitride photocatalysts prepared under different salt concentrations

[0068] Dissolve 0.25g of melamine and 0.25g of cyanuric acid in 20mL of DMSO solvent respectively, ultrasonicate for 30min, then mix the two solutions, centrifuge, wash with ethanol and water to obtain a solid substance. Prepare 20mL salt solution, its mass concentration is respectively 50, 125, 250 and 375mg / mL (wherein NaCl and KNO 3 The mass ratio is 1:3), and 0.5g of solid matter was added respectively, and after dispersion, it was quickly frozen with liquid nitrogen, and dried in a freeze dryer for 24 hours. The obtained powder was placed in a muffle furnace and heated to 350°C at a heating rate of 2.5°C / min, and kept for 30min. After cooling to room temperature, they were washed several times with deionized water to remove residual salt, and dried overnight at 60°C to prepare cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com