Normal-temperature gas-phase dechlorinating agent and preparation method thereof

A gas-phase dechlorination, room temperature technology, applied in chemical instruments and methods, molecular sieve catalysts, other chemical processes, etc., can solve the problems of unsatisfactory dechlorination performance of dechlorination agents, achieve rich specific surface, reduce usage, The effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of LDH-type complexes

[0039] Dissolve 297.9g of zinc nitrate hexahydrate in 1000g of water, stir well to dissolve it, then add 377.13g of aluminum nitrate nonahydrate under stirring conditions, stir well to dissolve it, and then add 50g of multi-stage porous Y molecular sieve powder , and then heat the mixed slurry to 60°C, slowly add 0.05mol / L ammonia solution under stirring condition, monitor the change of pH of the mixed solution, stop adding ammonia water when the pH reaches about 9.5. Under stirring, the mixture was continued to react for 12h.

[0040] Performance evaluation of dechlorination agent

[0041] Fill a glass reaction tube with a diameter of about 20mm with 40.0±0.05g of dechlorinating agent sample. Through a gas generator, a mixed gas with a hydrogen chloride concentration of 2.5-5 mg / L is obtained, and the carrier gas is nitrogen (containing 10% v propylene). Titrate the concentration of hydrogen chloride in the feed gas every 2 hours ...

Embodiment 2

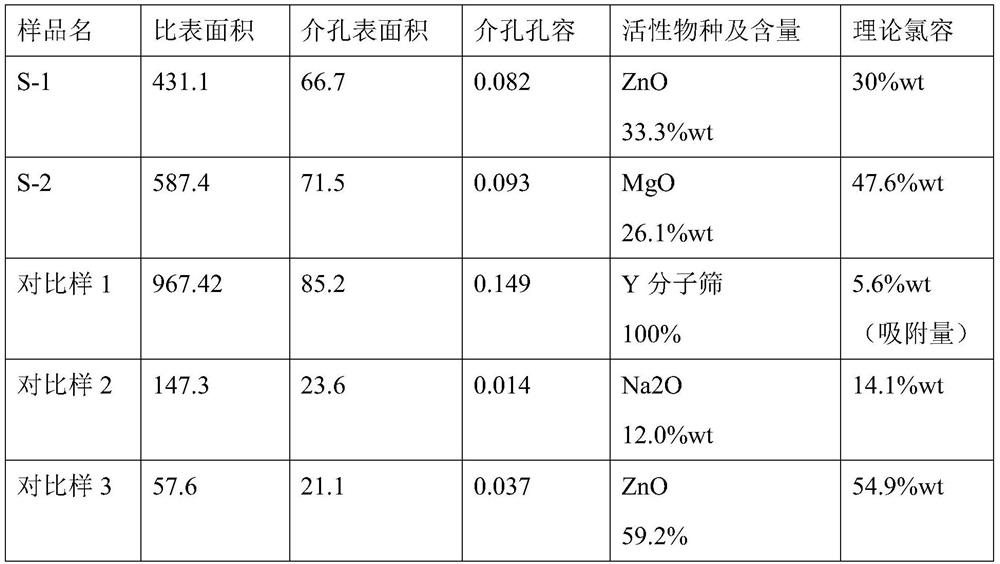

[0043] The mixed liquid in Example 1 was mixed with 60 g of attapulgite, and after wet grinding, the mixed slurry was dried to obtain a solid powder, and the obtained solid powder was molded to obtain a bar-shaped dechlorination agent. The sample was calcined at 400°C for 1.5 hours to obtain a strip-shaped dechlorination agent sample, denoted as S-1, with a diameter of 2.7mm. After testing, the chlorine capacity of the original particle size was 35.9%wt.

Embodiment 3

[0045] Add 441g.5g of magnesium nitrate to 2000g of water, stir well to dissolve it, then add 592.4g of aluminum nitrate nonahydrate under stirring conditions, stir well to dissolve it, and then add 200g of multi-level porous Y molecular sieve powder , and then heat the mixed slurry to 60°C, slowly add 0.05mol / L ammonia solution under stirring condition, monitor the change of pH of the mixed solution, stop adding ammonia water when the pH reaches about 9.5. Under stirring, the mixture was continued to react for 12h. Add 60g carrier, adopt the similar processing method of embodiment 2 to obtain bar-shaped dechlorination and sample, denoted as S-2, after testing the chlorine capacity of the original particle size of the sample is 55.2%wt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com