A kind of 3D printing monolithic composite structure catalyst and its preparation method and application

A composite structure, 3D printing technology, applied in catalyst activation/preparation, carbon compound catalysts, catalysts, etc., can solve the problems of limited effective reaction area and reaction time, large temperature gradient of catalyst bed, and low strength of catalyst carrier, etc. Fast and stable preparation, cheap and easy to obtain, and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the 3D printing monolithic composite structure catalyst of the present invention comprises the following steps:

[0032] Step 1: Use 3D model design software to make a corresponding three-dimensional model with a channel structure, which can be in various forms such as porous, circular, honeycomb, and mesh, and convert the format of the 3D model into a binary format.

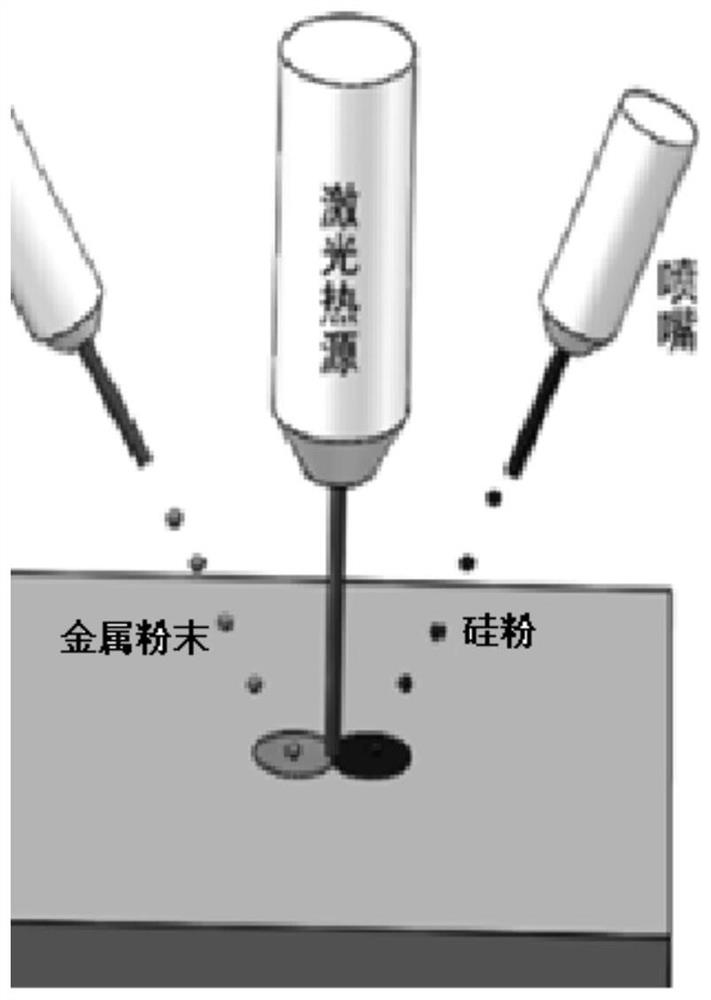

[0033] Step 2: Prepare the powder for metal 3D printing. The powder is divided into active component powder and carrier powder. The active component powder can be catalyzed by nickel, copper, cobalt, iron, titanium, vanadium, cerium, zirconium, etc. The active metal element, the carrier powder is silicon powder, and the particle size of the above powder is required to be less than 100 microns, so as to facilitate powder transportation.

[0034] Step 3: Design catalyst printing formula, adjust the ratio of active component metal powder and carrier powder to obtain catalysts with d...

Embodiment 1

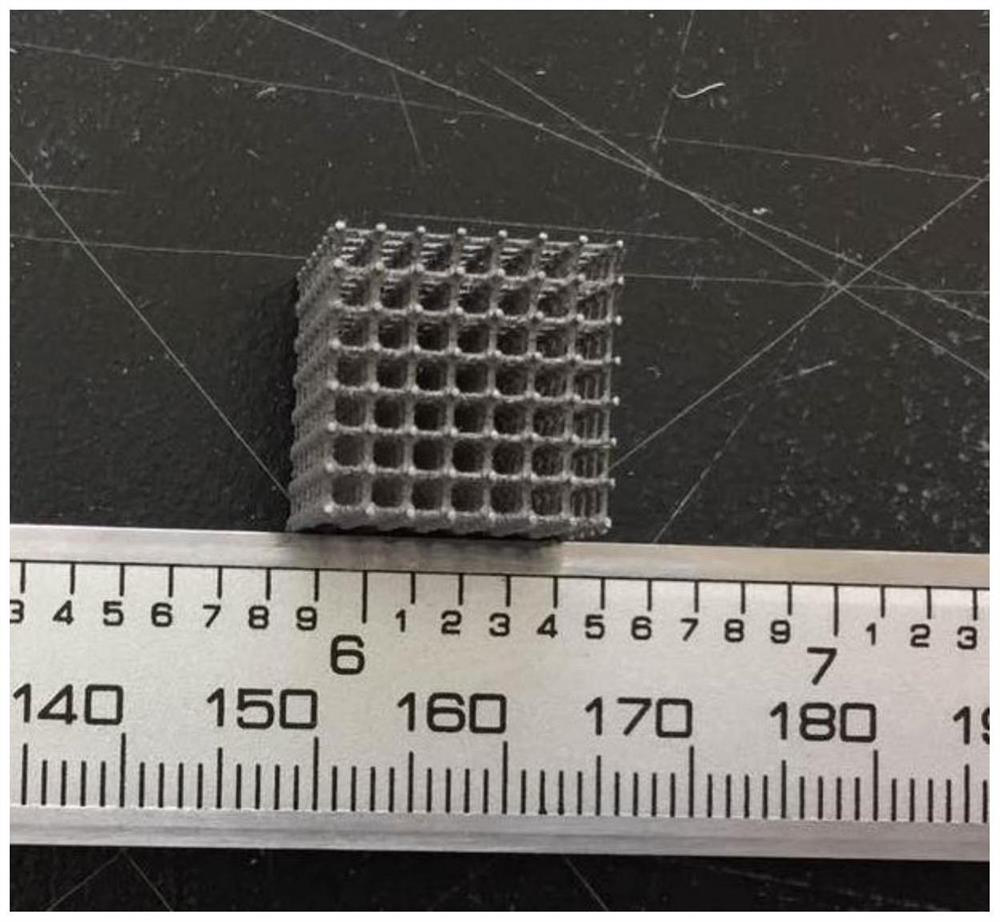

[0044] Step 1: Use 3D model design software to make a corresponding three-dimensional model with a channel structure in the form of a dot matrix. The diameter of each point is 0.5 mm, the distance between points is 2 mm, and the points are connected The diameter of the wire is 0.5 mm, the three-dimensional structure is a matrix of 8×8×8, and the format of the 3D model is converted into a binary format.

[0045] Step 2: Prepare the powder for metal 3D printing. The powder is divided into active component powder and carrier powder. The active component powder is nickel metal element powder with catalytic activity, and the carrier powder is easy to be dissolved by lye. of silica fume. The particle size of the above-mentioned powder is required to be less than 100 microns in order to facilitate powder transportation.

[0046] Step 3: Select the ratio of nickel:silicon to be 1:2, this catalyst formula is especially suitable for methanation reaction.

[0047] Step 4: Program the b...

Embodiment 2

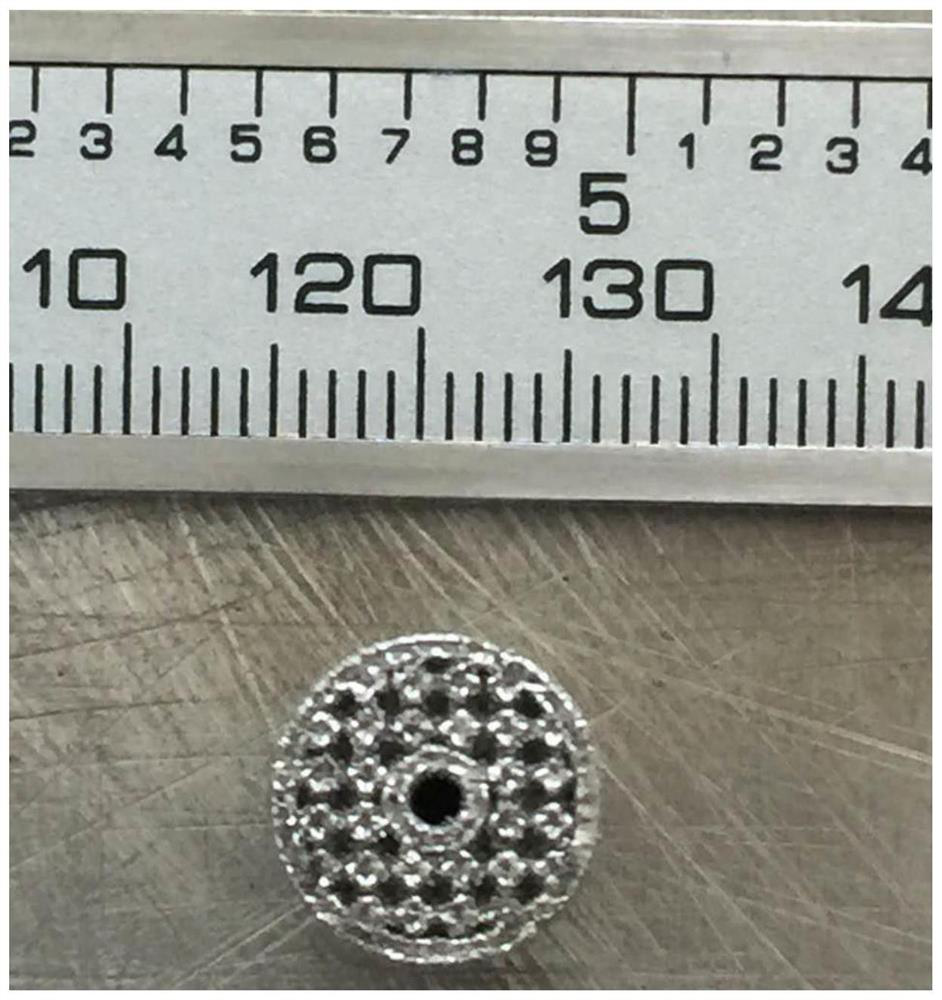

[0051] Step 1: Use 3D model design software to make a corresponding three-dimensional model with a channel structure. It adopts a circular honeycomb form. The diameter of the outer ring is 10 mm, and the diameter of the inner ring is 1.5 mm. Channels, 8 mm thick, and convert the format of the 3D model to binary format.

[0052] Step 2: Prepare the powder for metal 3D printing. The powder is divided into active component powder and carrier powder. The active component powder is nickel metal element powder with catalytic activity, and the carrier powder is easy to be dissolved by lye. of silica fume. The particle size of the above-mentioned powder is required to be less than 100 microns in order to facilitate powder transportation.

[0053] Step 3: Select the ratio of nickel:silicon to be 1:2, this catalyst formula is especially suitable for methanation reaction.

[0054] Step 4: Program the binary information, determine the structural outline in the programming software, plan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com