Aluminum profile processing wastewater treatment process

A technology for aluminum profile processing and wastewater treatment, applied in metallurgical wastewater treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. Low problems, to achieve the effect of improving the reuse rate, protecting the environment, and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

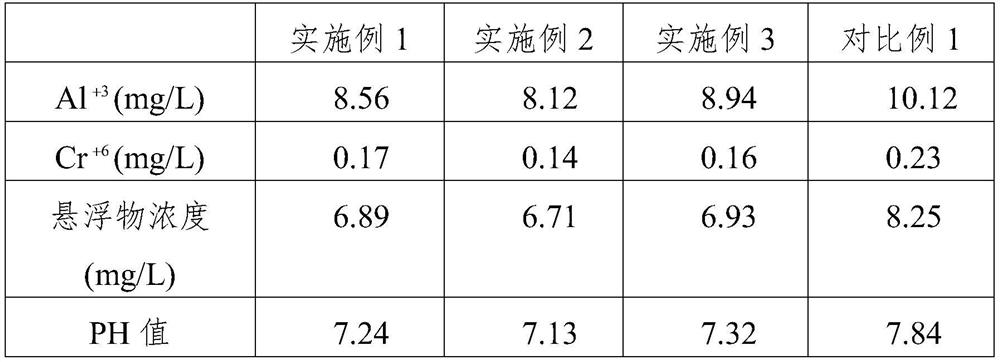

Examples

Embodiment 1

[0040]A process for treating wastewater from processing aluminum profiles, comprising the following steps:

[0041] S1: the cleaning waste water of degreasing, alkali washing and pickling is mixed, and self-neutralization is carried out to obtain neutralized waste water;

[0042] S2: Add a regulator to the neutralized waste water to adjust the pH value after mixing, and generate precipitation at the same time; the cleaning waste water in the degreasing and pickling process is acidic, and the alkaline washing cleaning waste water is alkaline, control the displacement of the two parts so that they can be mixed and neutralized by themselves The final pH is close to neutral, and the pH value is detected by a pH value detector, and a regulator is added according to the value to control the pH value to 7-8. The regulator is the waste liquid of the alkali etching tank or NAOH solution in the alkali cleaning process, which is mixed by itself Postformation is mainly ALOH 3 The precipi...

Embodiment 2

[0049] A process for treating wastewater from processing aluminum profiles, comprising the following steps:

[0050] S1: the cleaning waste water of degreasing, alkali washing and pickling is mixed, and self-neutralization is carried out to obtain neutralized waste water;

[0051] S2: Add a regulator to the neutralized waste water to adjust the pH value after mixing, and generate precipitation at the same time; the cleaning waste water in the degreasing and pickling process is acidic, and the alkaline washing cleaning waste water is alkaline, control the displacement of the two parts so that they can be mixed and neutralized by themselves The final pH is close to neutral, and the pH value is detected by a pH value detector, and a regulator is added according to the value to control the pH value to 7-8. The regulator is the waste liquid of the alkali etching tank or NAOH solution in the alkali cleaning process, which is mixed by itself Postformation is mainly ALOH 3 The precip...

Embodiment 3

[0058] A process for treating wastewater from processing aluminum profiles, comprising the following steps:

[0059] S1: the cleaning waste water of degreasing, alkali washing and pickling is mixed, and self-neutralization is carried out to obtain neutralized waste water;

[0060] S2: Add a regulator to the neutralized waste water to adjust the pH value after mixing, and generate precipitation at the same time; the cleaning waste water in the degreasing and pickling process is acidic, and the alkaline washing cleaning waste water is alkaline, control the displacement of the two parts so that they can be mixed and neutralized by themselves The final pH is close to neutral, and the pH value is detected by a pH value detector, and a regulator is added according to the value to control the pH value to 7-8. The regulator is the waste liquid of the alkali etching tank or NAOH solution in the alkali cleaning process, which is mixed by itself Postformation is mainly ALOH 3 The precip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com