a metallic glitter paint

A metal flash paint and organic solvent technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of unstable metal flash paint, easy condensation of resin molecular chains, and restrictions on the development of metal flash paint, and achieve good results. Ultraviolet radiation resistance, easy construction, good self-repair and anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

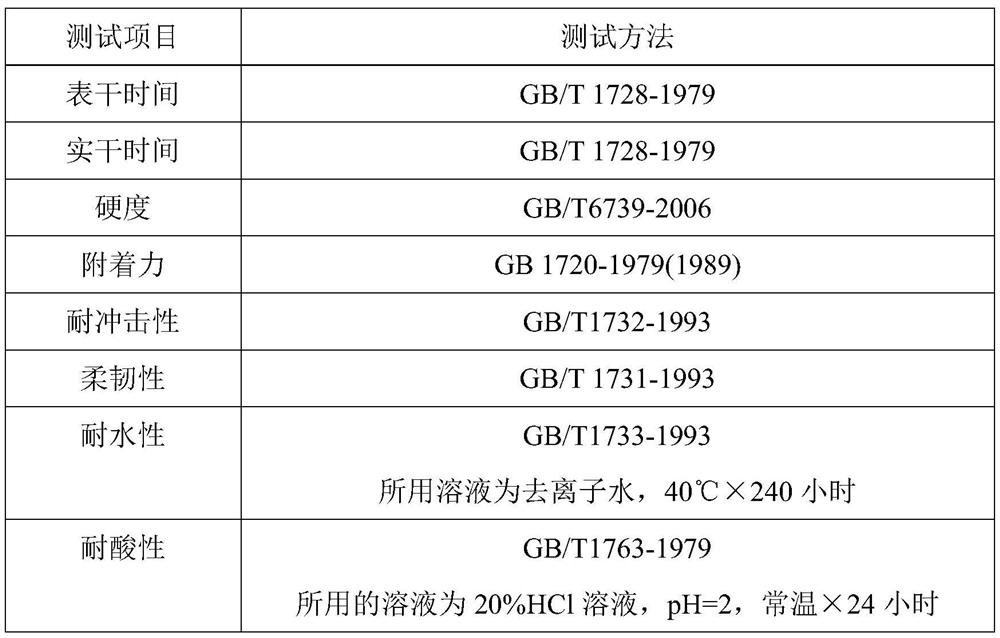

[0025] 1. Preparation of Epoxy Resin

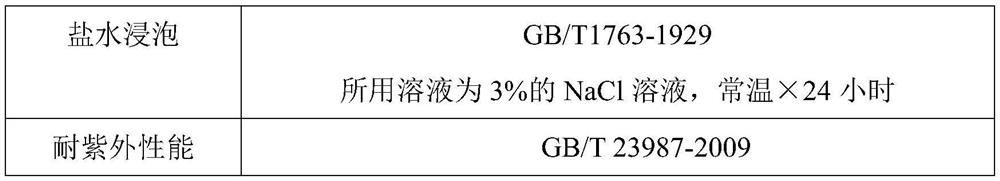

[0026] (1) Preparation of epoxy resin I

[0027] Taking maleimide as raw material, according to the following synthetic route, the obtained structural formula is The product is epoxy resin I.

[0028]

[0029] (2) Preparation of epoxy resin II

[0030]

[0031]

[0032] Taking maleimide as raw material, according to the above synthetic route, the obtained structural formula is The product is epoxy resin II.

[0033] 2. Preparation of Amino Resin

[0034] Using tetramethylurea, oxalyl chloride and 1,8-diaminooctane as raw materials, according to the following synthetic route, the obtained structural formula is The product is amino resin I.

[0035]

Embodiment 2

[0037] 1. Prepare metallic glitter paint

[0038] In this example, 4 treatment groups were set up, which were respectively marked as treatment IA, treatment IIA, treatment IIIA and treatment IVA, and the raw materials for each treatment group were prepared according to the formula provided in Table 2 for preparing metallic glitter paint. In Table 2, Epoxy Resin I and Epoxy Resin II correspond to Epoxy Resin I and Epoxy Resin II prepared in Example 1 respectively, and the structure of 1,4-dihydromaleimide butane is The amino resin I used is the amino resin I prepared in Example 1.

[0039] Table 2 embodiment 2 each processing group is used to prepare the formula composition (mass part number) of metal glitter paint

[0040]

[0041] After completing the material preparation, each treatment group correspondingly prepares the metallic glitter paint according to the following steps, and the addition amount of each group of materials is consistent with that in Table 2.

[004...

Embodiment 3

[0055] 1. Prepare metallic glitter paint

[0056] In this embodiment, 4 treatment groups are set up, which are respectively marked as treatment IB, treatment IIB, treatment IIIB and treatment IVB. According to the formula provided in Table 4, the raw materials for preparing metallic glitter paints for each treatment group are respectively prepared. In Table 4, the amino resin I is the amino resin I prepared in Example 1.

[0057] Table 4 embodiment 3 each treatment group is used to prepare the formula composition (mass part number) of metal glitter paint

[0058] Material type Treatment IB Treatment IIB Treatment IIIB Treatment IVB Epoxy resin Ⅰ 34 copies 34 copies 34 copies 34 copies Aluminum paste 10 copies 10 copies 10 copies 10 copies polyamide wax 20 copies 20 copies 29 copies Amino resin Ⅰ 9 servings 29 copies Melamine 9 servings Xylene 15 copies 15 copies 15 copies 15 copies ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com