Method for wrapping copper powder with graphene

A technology for wrapping graphene and copper powder, applied in transportation and packaging, gaseous chemical plating, coating, etc., can solve problems such as unfavorable wrapping of graphene, loss of copper powder properties, affecting copper powder performance, etc., to improve anti-oxidation Improved performance, antioxidant capacity, high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

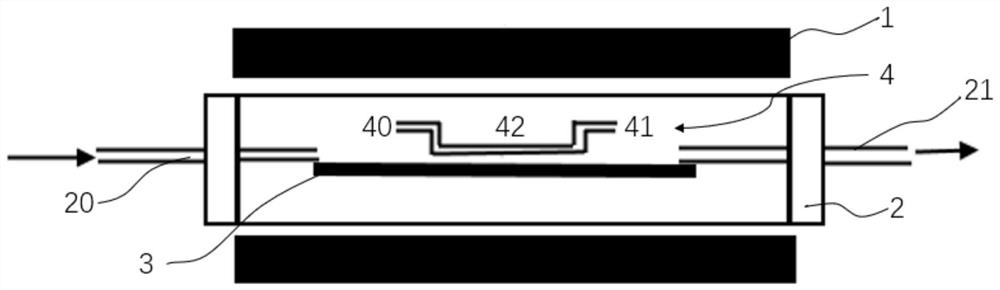

[0047] S1, put the mixed powder of copper powder and magnesium oxide powder in figure 1 In the U-shaped quartz tube shown (the mixed powder is in the tube of the storage part 42 under the action of gravity), the U-shaped quartz tube is placed in the center of the substrate holder in the middle of the heat-resistant tube; 300 SCCM Ar and 500 SCCM H 2 After 30 minutes of ventilation, start heating the furnace body 1, so that the temperature of the substrate support in the furnace body reaches 1000 ° C, and anneal at this temperature for 30 minutes;

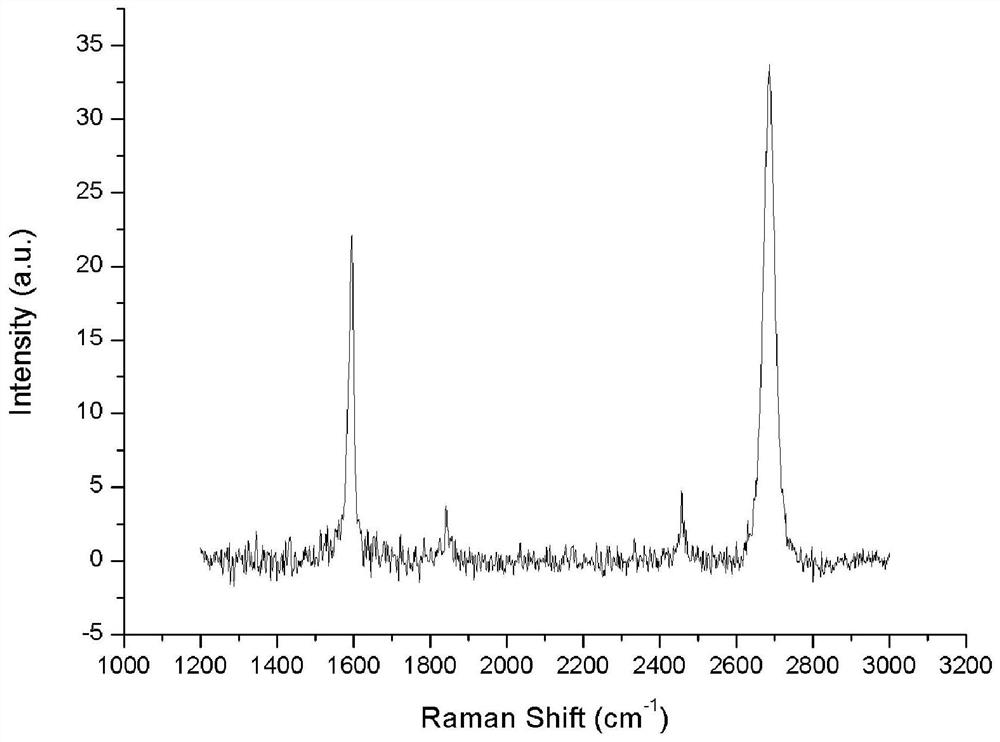

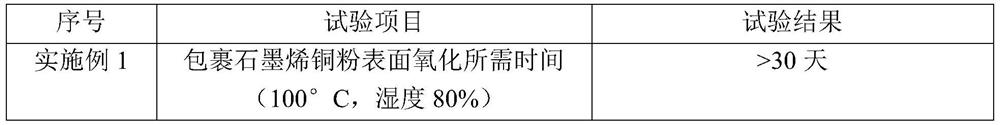

[0048] S2. After annealing, feed 50 SCCM methane into the heat-resistant tube as the carbon source gas, and keep the heat-resistant tube at normal pressure 1 atm at the same time, and the reaction starts; stop feeding methane after 10 minutes of reaction, and continue feeding 300 SCCM Ar and 500 SCCM SCCM H 2 After the temperature in the furnace is slowly cooled (at a rate of about 1°C / s) to room temperature, the sample is taken out...

Embodiment 2

[0052] S1, put the mixed powder of copper powder and magnesium oxide powder in figure 1 In the U-shaped quartz tube shown, the U-shaped quartz tube is placed in the center of the substrate holder in the middle of the heat-resistant tube; the air in the heat-resistant tube is pumped out with a vacuum pump and 300 SCCM Ar and 500 SCCM H are introduced 2 After 30 minutes of ventilation, start to heat the furnace body 1, so that the temperature of the substrate support in the furnace body reaches 800 ° C, and anneal at this temperature for 60 minutes;

[0053] S2. After annealing, pass 50 SCCM acetylene into the heat-resistant tube as the carbon source gas, and keep the heat-resistant tube at normal pressure 1atm at the same time, and the reaction starts; stop feeding acetylene after 10 minutes of reaction, and continue to pass 300 SCCM Ar and 500 SCCM H 2 After the temperature in the furnace cools down (at a rate of about 5°C / s) to room temperature, take out the sample;

[0054...

Embodiment 3

[0057] S1, put the mixed powder of copper powder and magnesium oxide powder in figure 1 In the U-shaped quartz tube shown, the U-shaped quartz tube is placed in the center of the substrate holder in the middle of the heat-resistant tube; the air in the heat-resistant tube is pumped out with a vacuum pump and 300 SCCM Ar and 500 SCCM H are introduced 2 After 30 minutes of ventilation, start heating the furnace body 1, so that the temperature of the substrate support in the furnace body reaches 1000 ° C, and anneal at this temperature for 30 minutes;

[0058] S2. After annealing, feed 60 SCCM methane into the heat-resistant tube as a carbon source gas, and keep the heat-resistant tube at a low pressure of 0.1 Torr at the same time, and the reaction starts; stop feeding methane after 0.1 minutes of reaction, and continue feeding 300 SCCM Ar and 500 SCCM h 2 After the temperature in the furnace cools down (at a rate of about 100°C / s) to room temperature, take out the sample;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com