A full-spectrum perovskite nanowire array and its preparation method

A nanowire array and perovskite technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of inability to prepare and cumbersome operation process, and achieve the effect of easy physical properties, convenient operation and complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Specifically, a method for preparing a full-spectrum perovskite nanowire array includes the following steps:

[0050] S1. Prepare the perovskite precursor solution in which the halogen group is bromine, that is, prepare the solute with the general molecular formula ABX 3 In X is the solution of the perovskite of Br;

[0051] S2, using a perovskite precursor solution to prepare a perovskite nanowire array;

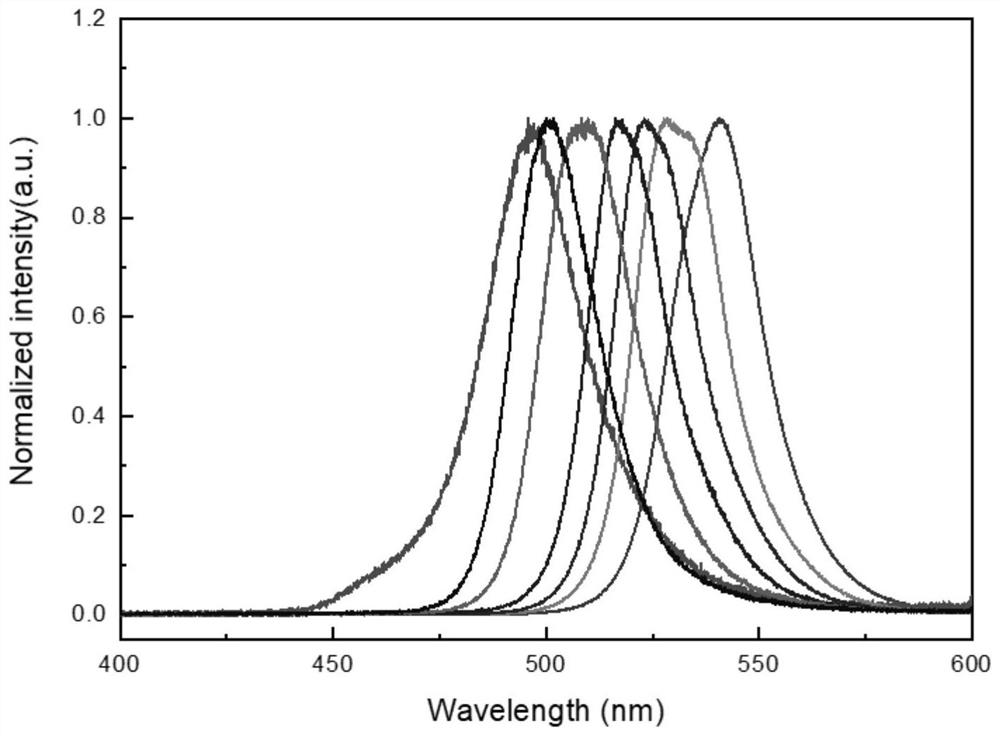

[0052] S3, prepare two kinds of ion exchange solutions containing chlorine and iodine in the solute respectively, for reaction replacement of bromine groups in the perovskite nanowire array;

[0053] S4. Soak one end of the perovskite nanowire array in an ion exchange solution thereof, and continuously pull the perovskite nanowire array; specifically, the perovskite nanowire array is fixed on the pulling rod of the pulling instrument through a clamp , and put the corresponding ion exchange solution in the crucible of the pulling instrument. During the ion exchange ...

Embodiment 1

[0090] S1, methylamine bromide (MABr) and lead bromide (PbBr 2 ) is dissolved in a mixed solution of N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) with a volume ratio of 1:1 at a molar mass ratio of 1:1, and is configured as a precursor with a concentration of 20 mg / ml Bulk solution, that is, MAPbBr formulated with bromine as the halogen group 3 Perovskite precursor solution;

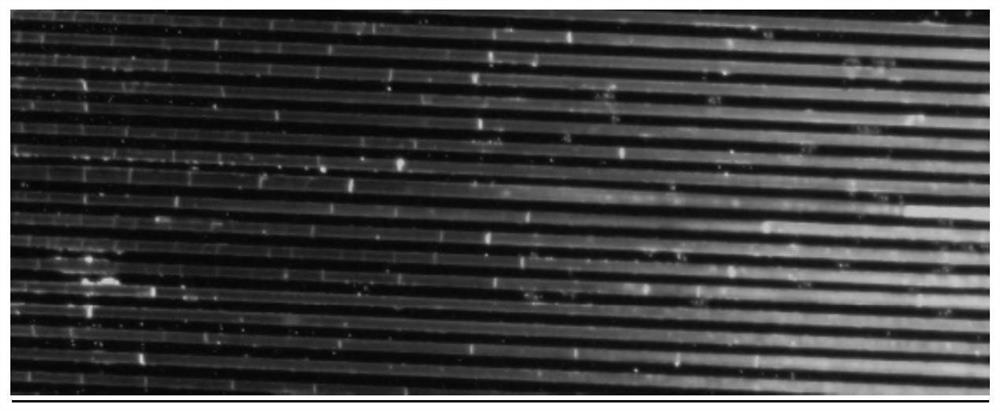

[0091] S2. Take 20 μL of MAPbBr 3 The perovskite precursor solution is directly added dropwise on the silica substrate, and the silicon pillar template containing the silicon pillar array is covered on the substrate to form a sandwich assembly system of substrate-perovskite precursor solution-silicon pillar template, and Place it in a vacuum oven at 60°C and heat it for 12 hours to crystallize by using the dewetting behavior. After the cooling sandwich assembly system is disassembled, MAPbBr can be obtained 3 Nano single crystal array;

[0092] S3, prepare two kinds of ion-exchange solut...

Embodiment 2

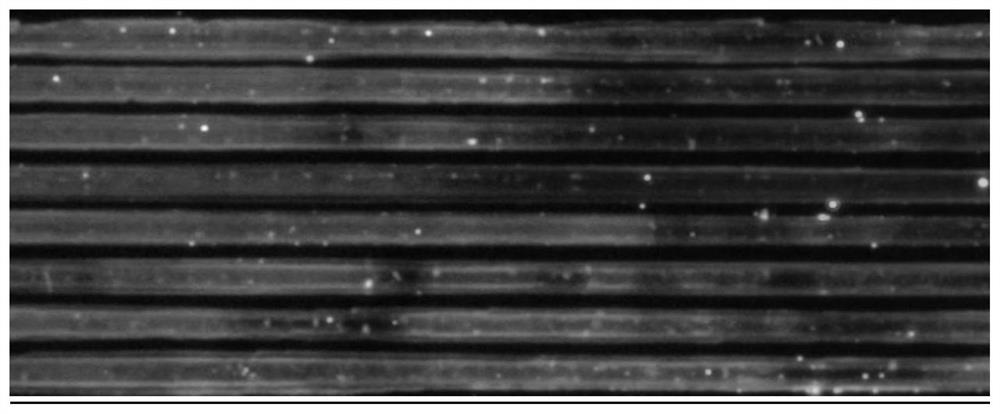

[0106] S1, cesium bromide (CsBr) and lead bromide (PbBr 2 ) is dissolved in a mixed solution of N,N-dimethylformamide (DMF) and dimethyl sulfoxide (DMSO) with a volume ratio of 1:1 at a molar mass ratio of 1:1, and is configured as a precursor with a concentration of 20 mg / ml Bulk solution, that is, the preparation of CsPbBr whose halogen group is bromine 3 Perovskite precursor solution;

[0107] S2. Take 20 μL of CsPbBr 3 The perovskite precursor solution is directly added dropwise on the silica substrate, and the silicon pillar template containing the silicon pillar array is covered on the substrate to form a sandwich assembly system of substrate-perovskite precursor solution-silicon pillar template, and Place in a vacuum oven at a temperature of 60°C and heat for 12 hours, crystallize by using the dewetting behavior, and CsPbBr can be obtained after cooling the sandwich assembly system and disassembling it. 3 Nano single crystal array;

[0108] S3, prepare two kinds of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com