High-performance flame-retardant polyester fiber and preparation method thereof

A high-performance flame-retardant polyester technology, which is applied in the field of high-performance flame-retardant polyester fiber and its preparation, can solve problems such as potential safety hazards, thermal degradation of bottle flakes, and high energy consumption in the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

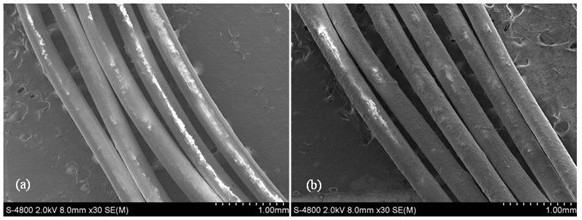

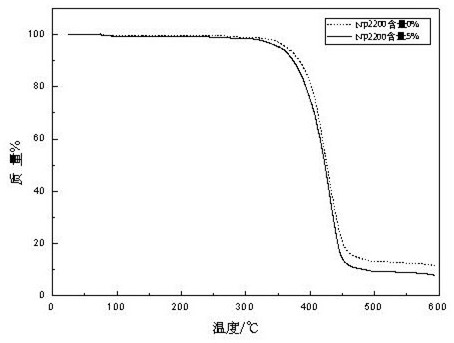

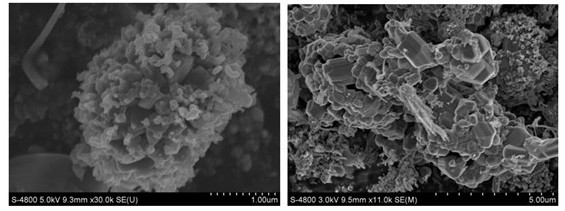

[0020] A high-performance flame-retardant polyester fiber. The raw material components of the high-performance flame-retardant polyester fiber are composed of colorless waste mineral water bottle flakes, cubic silicon carbide β-SiC with a particle size of 20um, and organic nitrogen-phosphorus flame retardant NP2200. The mass ratio It is 90:5:5.

[0021] A preparation method of high-performance flame-retardant polyester fiber, the specific steps are as follows:

[0022] (1) Use a colorless waste mineral water bottle, ultrasonically clean it with a 1:1 alcohol-water mixture for 30 minutes, blow dry it at room temperature, and break it into 0.5*0.6cm bottle pieces.

[0023] (2) Weigh each raw material component of the above-mentioned high-performance flame-retardant polyester fiber, and then divide the bottle flakes into two parts, one of which is 50% of the total mass of the bottle flakes; mix the weighed silicon carbide and flame retardant evenly .

[0024] (3) Place 50% of t...

Embodiment 2

[0036] A high-performance flame-retardant polyester fiber. The raw material components of the high-performance flame-retardant polyester fiber are colorless waste mineral water bottle flakes, cubic silicon carbide β-SiC with a particle size of 16um, and two organic nitrogen and phosphorus flame retardants NP2200 and NP2800. Composition, the mass ratio is 80:2:15:3.

[0037] A preparation method of high-performance flame-retardant polyester fiber, the specific steps are as follows:

[0038] (1) Choose a colorless waste mineral water bottle, ultrasonically clean it with a 1:1 alcohol-water mixture for 35 minutes, blow dry it at room temperature, and break it into 0.5*0.6cm bottle pieces.

[0039] (2) Weigh each raw material component of the above-mentioned high-performance flame-retardant polyester fiber, and then divide the bottle flakes into two parts, one of which is 40% of the total mass of the bottle flakes; mix the weighed silicon carbide and flame retardant evenly .

[...

Embodiment 3

[0052] A high-performance flame-retardant polyester fiber, the raw material components of the high-performance flame-retardant polyester fiber are colorless waste mineral water bottle flakes, cubic silicon carbide β-SiC with a particle size of 5um, and two kinds of organic nitrogen and phosphorus flame retardants NP2200 and NP2800 Composition, the mass ratio is 65:5:20:10.

[0053] A preparation method of high-performance flame-retardant polyester fiber, the specific steps are as follows:

[0054] (1) Use a colorless waste mineral water bottle, ultrasonically clean it with a 1:1 alcohol-water mixture for 30 minutes, blow dry it at room temperature, and break it into 0.5*0.6cm bottle pieces.

[0055] (2) Weigh each raw material component of the above-mentioned high-performance flame-retardant polyester fiber, and then divide the bottle flakes into two parts, one of which is 70% of the total mass of the bottle flakes; mix the weighed silicon carbide and flame retardant evenly . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com