Preparation method of titanate fiber membrane

A fiber membrane, titanate technology, used in spinning solution preparation, fiber chemical characterization, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

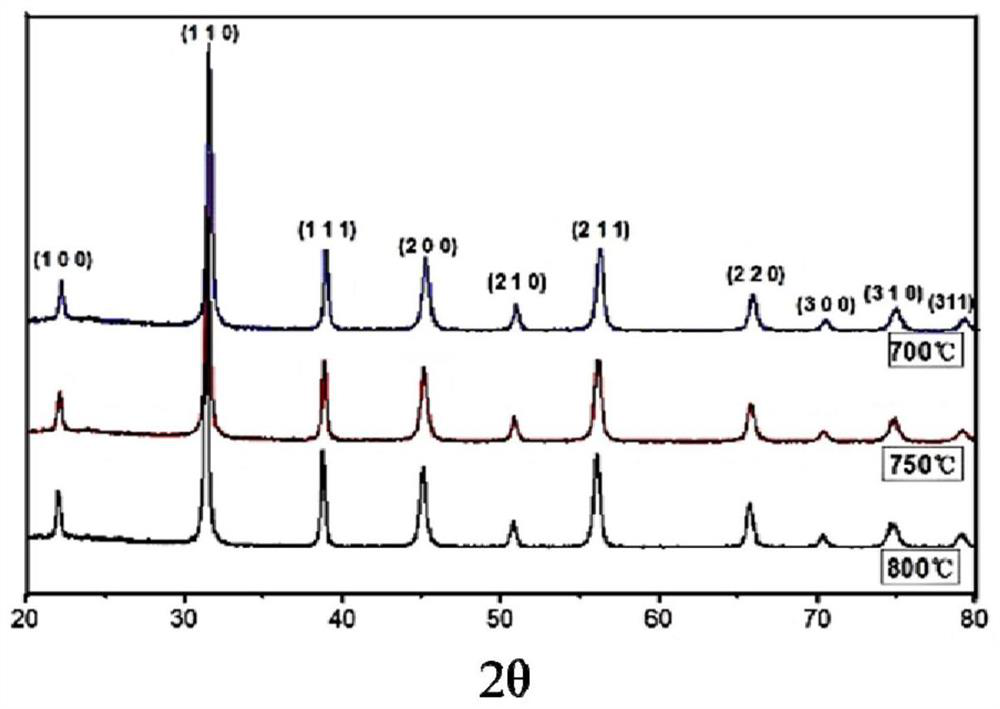

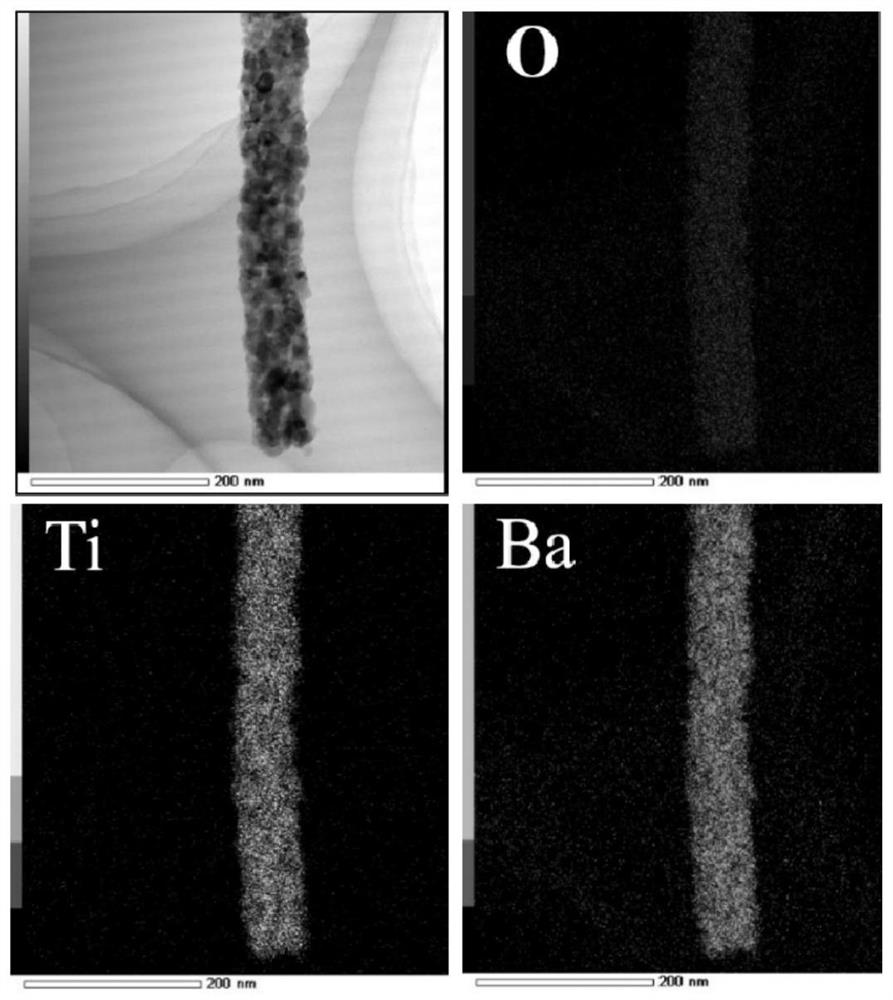

[0044] This embodiment provides a barium titanate ceramic nanofiber membrane, which is prepared according to the following steps:

[0045] (1) Preparation of barium titanate spinning solution

[0046] 1 g of PVP with a molecular weight of 13W was dissolved in 15 g of ethanol, and subjected to magnetic stirring at room temperature for 5 h to obtain a polymer solution. 1.5 g of barium acetate was dissolved in 10 g of glacial acetic acid, and ultrasonically oscillated for 10 minutes to obtain a barium acetate solution. The obtained polymer solution was added to the barium acetate solution, and magnetically stirred at room temperature for 4 hours to obtain a mixed solution, and 2 g of tetrabutyl titanate was added to the mixed solution to obtain a spinning solution.

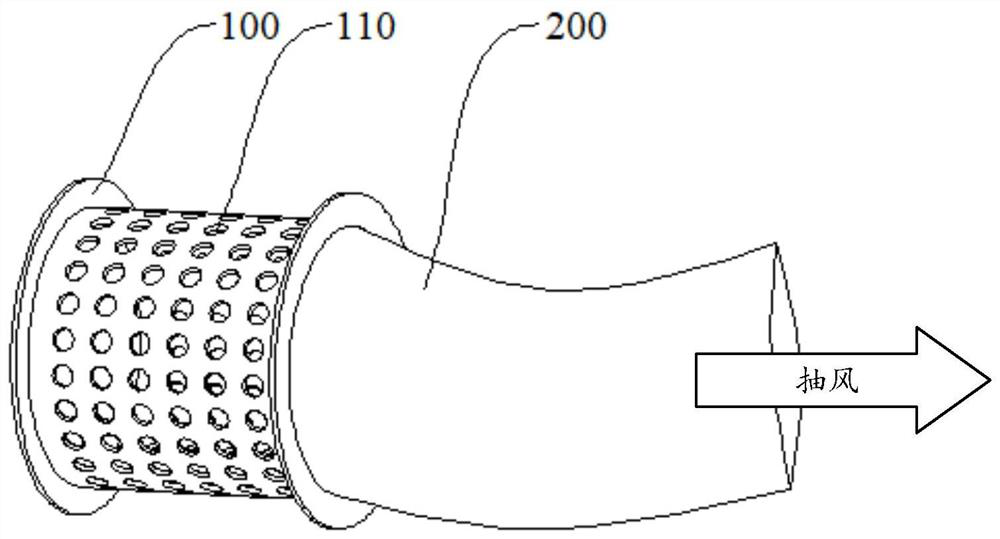

[0047] (2) Preparation of barium titanate precursor fiber membrane by air spinning

[0048] The obtained barium titanate spinning solution is put into an air spinning device for air spinning to obtain a barium tita...

Embodiment 2

[0054] This embodiment provides a strontium titanate ceramic nanofiber membrane, which is prepared according to the following steps:

[0055] (1) Preparation of strontium titanate spinning solution

[0056] 1.5 g of PVP with a molecular weight of 13W was dissolved in 20 g of ethanol, and subjected to magnetic stirring at room temperature for 5 h to obtain a polymer solution. 1.18 g of strontium acetate was dissolved in 15 g of glacial acetic acid, and ultrasonically oscillated for 10 minutes to obtain a strontium acetate solution. The obtained polymer solution was added to the strontium acetate solution, and a mixed solution was obtained after magnetic stirring at room temperature for 4 hours, and 2 g of tetrabutyl titanate was added to the mixed solution to obtain a spinning solution.

[0057] (2) Preparation of strontium titanate precursor fiber membrane by air spinning

[0058] The obtained strontium titanate spinning solution is put into an air spinning device for air sp...

Embodiment 3

[0064] This embodiment provides a barium strontium titanate ceramic nanofiber membrane, which is prepared according to the following steps:

[0065] (1) Preparation of barium strontium titanate spinning solution

[0066] 1.5 g of PVP with a molecular weight of 13W was dissolved in 15 g of ethanol, and subjected to magnetic stirring at room temperature for 5 h to obtain a polymer solution. Dissolve 0.35g of strontium acetate and 1.05g of barium acetate in 10g of glacial acetic acid, ultrasonically vibrate for 10 minutes to obtain a mixed solution of strontium acetate and barium acetate, then add the obtained polymer solution to it, and stir magnetically at room temperature for 5 hours to obtain a mixed solution , 2 g of tetrabutyl titanate was added into the mixed solution to obtain a spinning solution.

[0067] (2) Preparation of strontium barium titanate precursor fiber membrane by air spinning

[0068] The obtained barium strontium titanate spinning solution is put into an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line speed | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com