Preparation method of titanate fiber membrane

A fiber membrane, titanate technology, used in spinning solution preparation, fiber chemical characterization, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

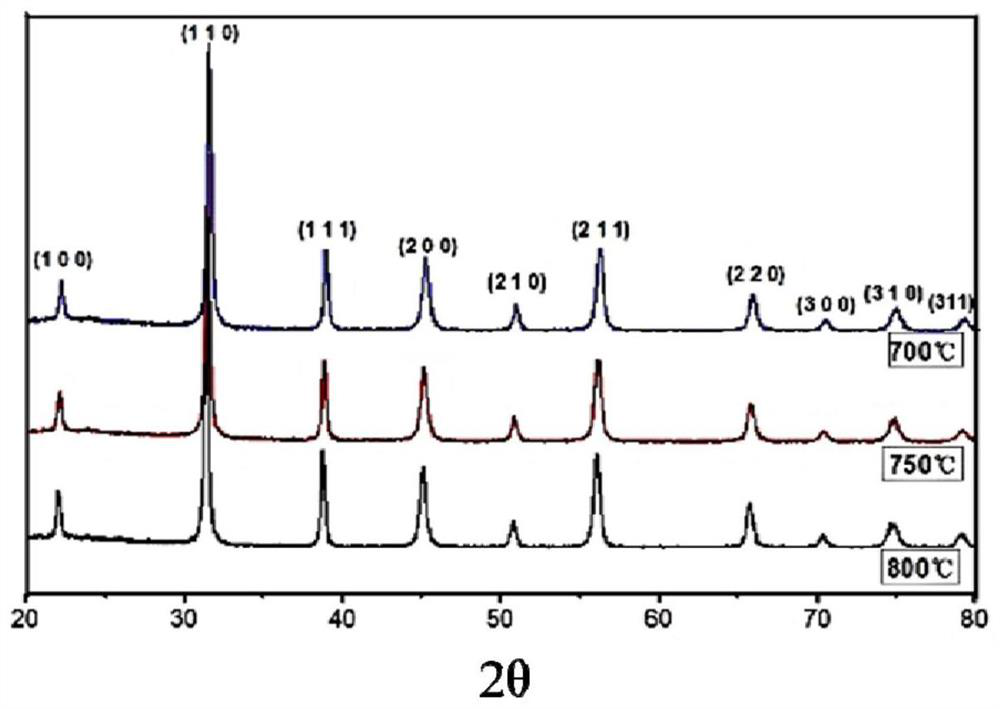

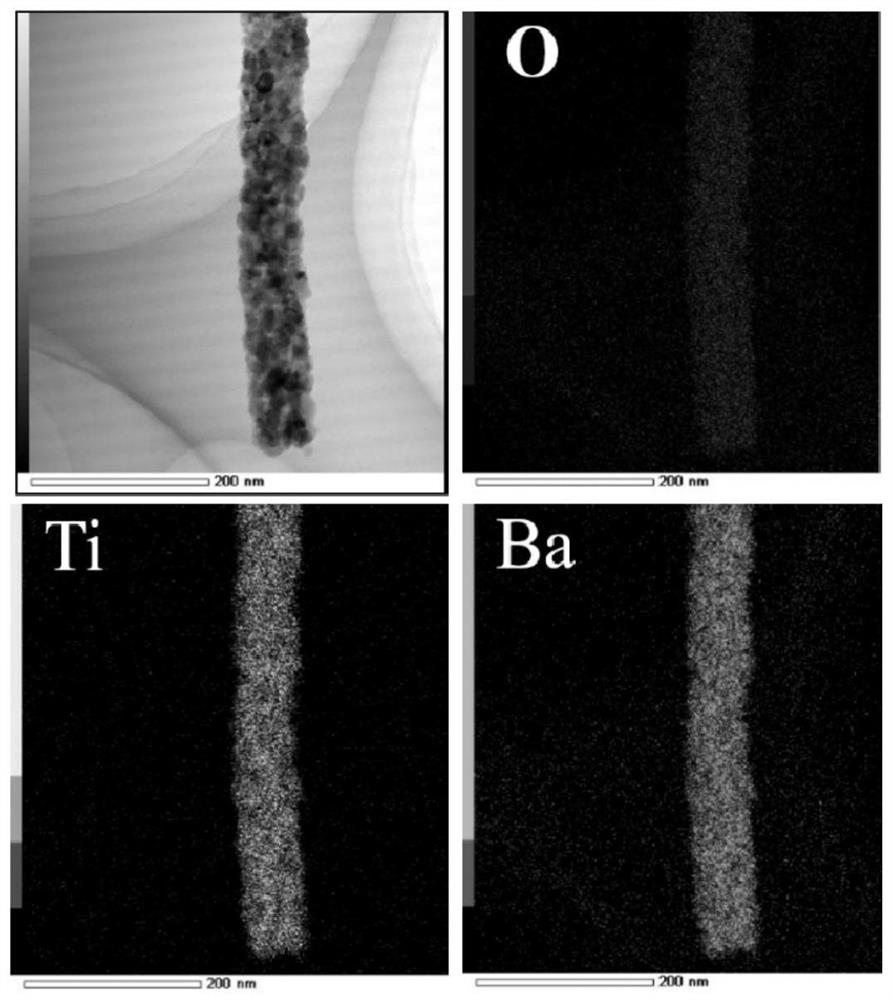

[0044] The present embodiment provides a barium titanate ceramic nanofiber membrane, which is prepared according to the following steps:

[0045] (1) Preparation of barium titanate spinning solution

[0046] 1 g of PVP with a molecular weight of 13W was dissolved in 15 g of ethanol, and a polymer solution was obtained by magnetic stirring at room temperature for 5 h. Dissolve 1.5 g of barium acetate in 10 g of glacial acetic acid, and ultrasonically vibrate for 10 minutes to obtain a barium acetate solution. The obtained polymer solution was added to the barium acetate solution, and the mixed solution was obtained by magnetic stirring at room temperature for 4 hours, and 2 g of tetrabutyl titanate was added to the mixed solution to obtain the spinning solution.

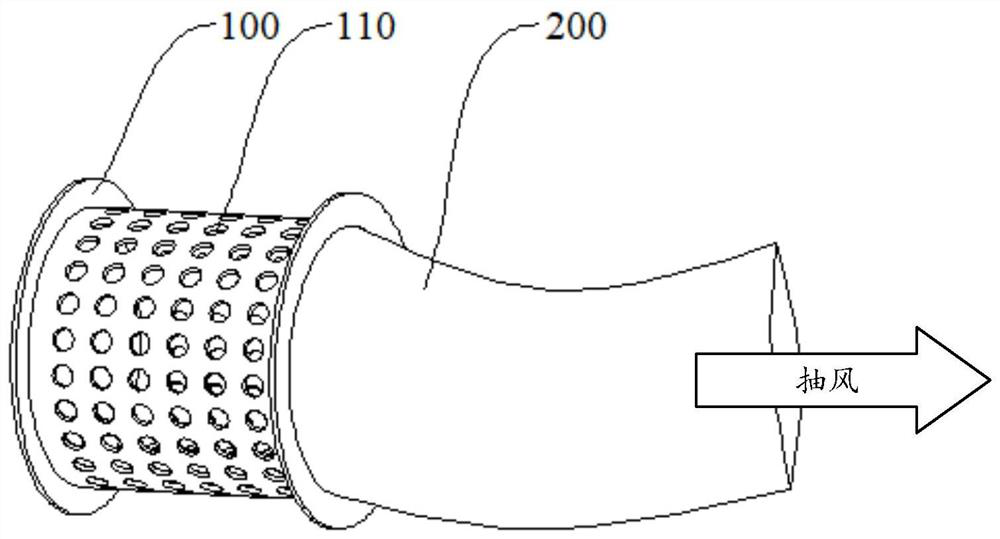

[0047] (2) Preparation of barium titanate precursor fiber membrane by air spinning

[0048] The obtained barium titanate spinning solution was put into an air spinning device for air spinning to obtain a barium tita...

Embodiment 2

[0054] This embodiment provides a strontium titanate ceramic nanofiber membrane, which is prepared according to the following steps:

[0055] (1) Preparation of strontium titanate spinning solution

[0056] 1.5g of PVP with a molecular weight of 13W was dissolved in 20g of ethanol, and the polymer solution was obtained by magnetic stirring at room temperature for 5h. Dissolve 1.18 g of strontium acetate in 15 g of glacial acetic acid, and ultrasonically vibrate for 10 minutes to obtain a strontium acetate solution. The obtained polymer solution was added to the strontium acetate solution, and a mixed solution was obtained by magnetic stirring at room temperature for 4 h, and 2 g of tetrabutyl titanate was added to the mixed solution to obtain a spinning solution.

[0057] (2) Preparation of strontium titanate precursor fiber membrane by air spinning

[0058] The obtained strontium titanate spinning solution was put into an air spinning device for air spinning to obtain a str...

Embodiment 3

[0064] The present embodiment provides a strontium barium titanate ceramic nanofiber membrane, which is prepared according to the following steps:

[0065] (1) Preparation of barium strontium titanate spinning solution

[0066] 1.5g of PVP with a molecular weight of 13W was dissolved in 15g of ethanol, and the polymer solution was obtained by magnetic stirring at room temperature for 5h. Dissolve 0.35g of strontium acetate and 1.05g of barium acetate in 10g of glacial acetic acid, ultrasonically shake for 10 minutes to obtain a mixed solution of strontium acetate and barium acetate, then add the obtained polymer solution to it, and obtain a mixed solution through magnetic stirring at room temperature for 5h , take 2g of tetrabutyl titanate and add it to the mixed solution to obtain spinning solution.

[0067] (2) Preparation of strontium barium titanate precursor fiber membrane by air spinning

[0068] The obtained barium strontium titanate spinning solution is put into an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com