Polyaniline/copper sulphide composite photocatalyst with dye adsorption-catalytic degradation function as well as preparation method and application of polyaniline/copper sulphide composite photocatalyst

A technology for catalytic degradation and polyaniline, applied in the direction of organic compound/hydride/coordination complex catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problems of high cost and complexity, and achieve low cost, Low production cost and improved degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A kind of preparation method of polyaniline / copper sulfide composite photocatalyst with adsorption-catalytic degradation dye function of the present invention, its steps are:

[0043] Step 1. Pipette 1.6mL of aniline solution into 50mL of 0.5mol / L hydrochloric acid solution with a pipette gun, and sonicate until uniformly mixed, and the sonication time is greater than or equal to 30min.

[0044] Step 2. Add a certain amount of ammonium persulfate solution dropwise to the solution obtained in step 1 while stirring: put the solution obtained in step 1 on a magnetic stirrer, add 4.56g dropwise while stirring, and dissolve in 50mL deionized The ammonium persulfate solution in water is fully reacted and stirred for 12 hours at 15±5°C, pH is 2-10, and the stirring speed is 100-150 r / min. The color of the solution gradually changed from transparent to dark green, indicating the formation of polyaniline.

[0045] Step 3, using in-situ precipitation reaction, in the solution of...

Embodiment 1

[0056] (1) Preparation of polyaniline: pipette 1.6mL of aniline solution into 50mL of 0.5mol / L hydrochloric acid solution with a pipette gun, and ultrasonically mix for 30min; then place the above solution on a magnetic stirrer and stir while stirring Add 4.56g of ammonium persulfate solution (dissolved in 50mL of deionized water) dropwise, and fully react and stir for 12 hours at 15±5°C, pH 2-10, stirring speed 100-150r / min. The color of the solution gradually changed from transparent to dark green, indicating the formation of polyaniline.

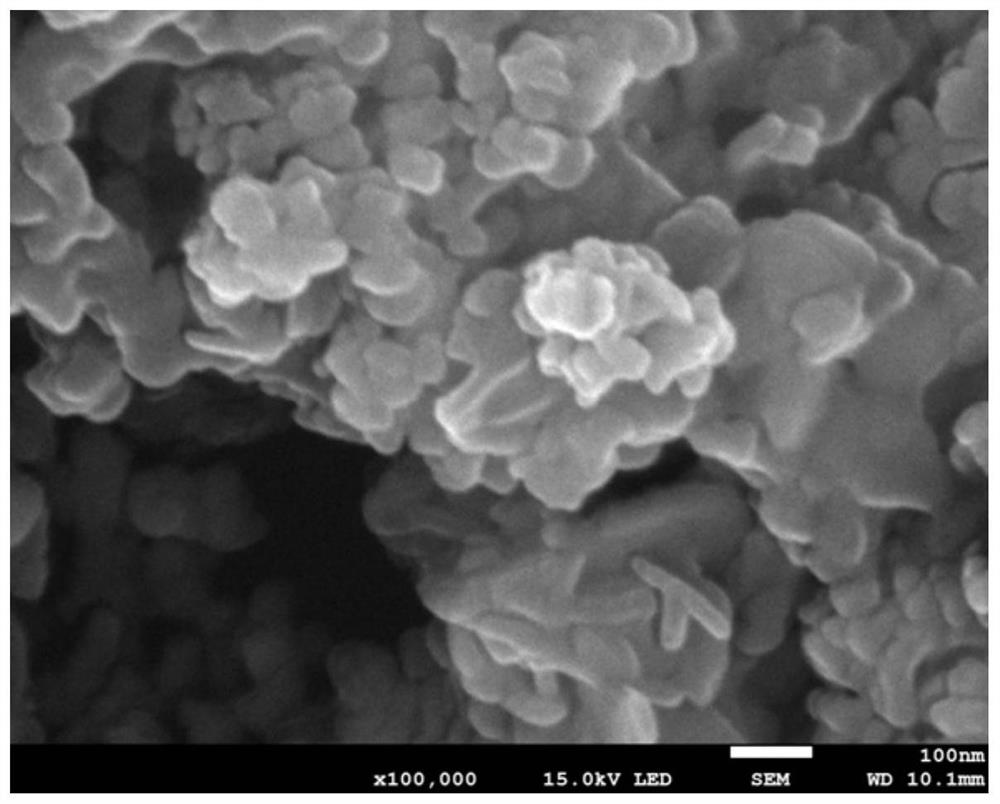

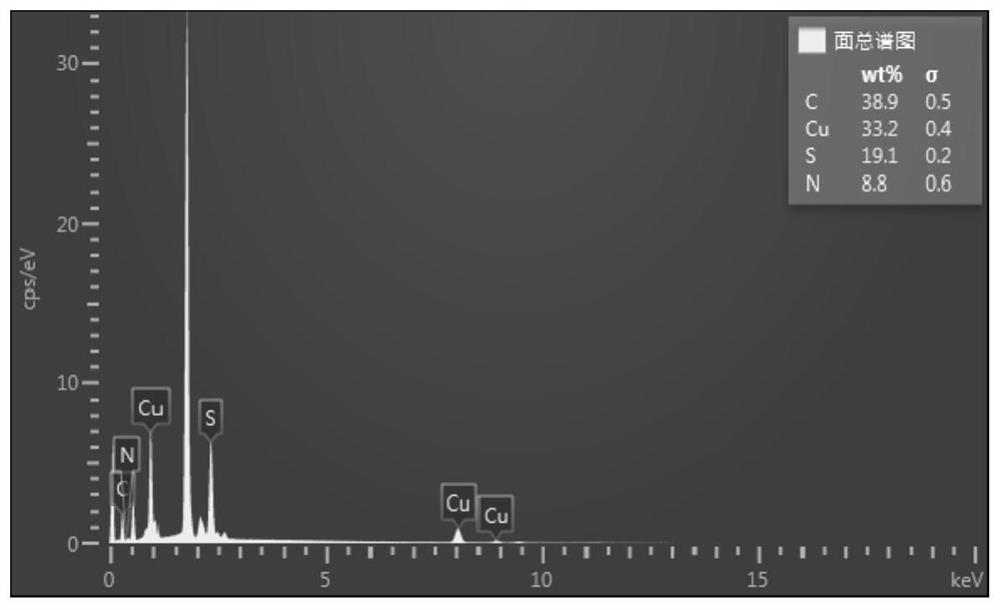

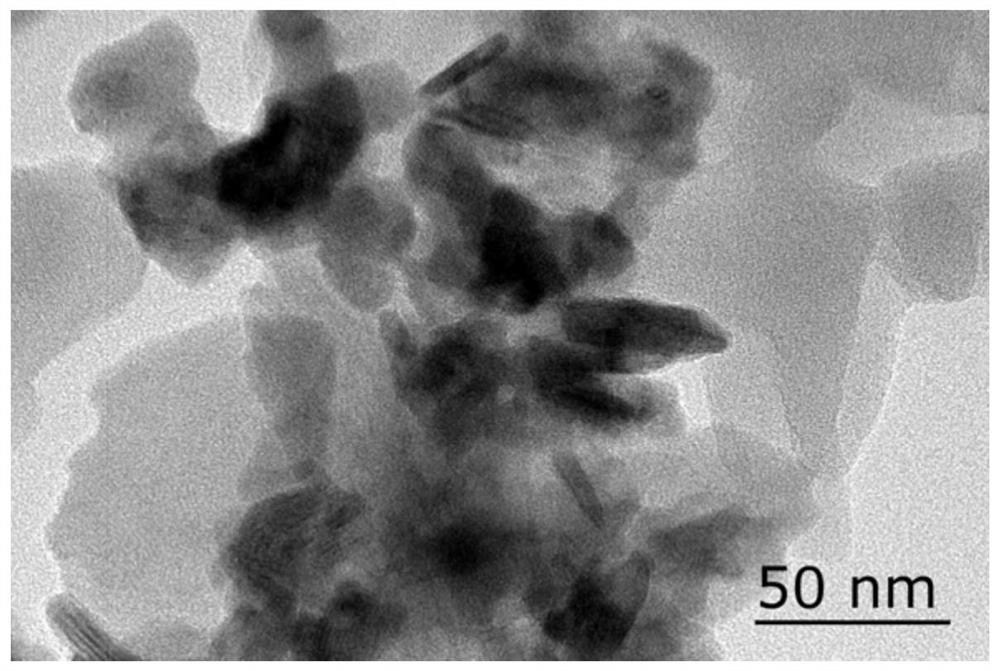

[0057] (2) In-situ loading of nano-copper sulfide: on the basis of polyaniline, add 50mL of 0.72mol / L copper nitrate solution dropwise while stirring, at 15±5°C, pH is 2-10, stirring speed is 100- Under the condition of 150r / min, fully react and stir for 12h; then add 50mL of 0.72mol / L Na 2 S solution, under the conditions of 15±5°C, pH 2-10, stirring speed 100-150r / min, fully react and stir for 12h; then use the polyaniline / copper sulfi...

Embodiment 2

[0061] (1) Preparation of polyaniline: pipette 1.6mL of aniline solution into 50mL of 0.5mol / L hydrochloric acid solution with a pipette gun, and ultrasonically mix for 30min; then place the above solution on a magnetic stirrer and stir while stirring Add 4.56g of ammonium persulfate solution (dissolved in 50mL of deionized water) dropwise, and fully react and stir for 12 hours at 15±5°C, pH 2-10, stirring speed 100-150r / min. The color of the solution gradually changed from transparent to dark green, indicating the formation of polyaniline.

[0062] (2) In-situ loading of nano-copper sulfide: on the basis of polyaniline, add 50mL of 0.36mol / L copper nitrate solution dropwise while stirring, at 15±5°C, pH is 2-10, stirring speed is 100- Under the condition of 150r / min, fully react and stir for 12h; then add 50mL of 0.36mol / L Na 2 S solution, under the conditions of 15±5°C, pH 2-10, stirring speed 100-150r / min, fully react and stir for 12h; then use the polyaniline / copper sulfi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com