Oxygen-enriched production process of catalyst-grade antimony trioxide

An antimony trioxide and production process technology, applied in the directions of antimony oxide/antimony hydroxide/antimony oxyacid, inorganic chemistry, antimony compounds, etc., can solve the problems of high fuel consumption and low heat utilization rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

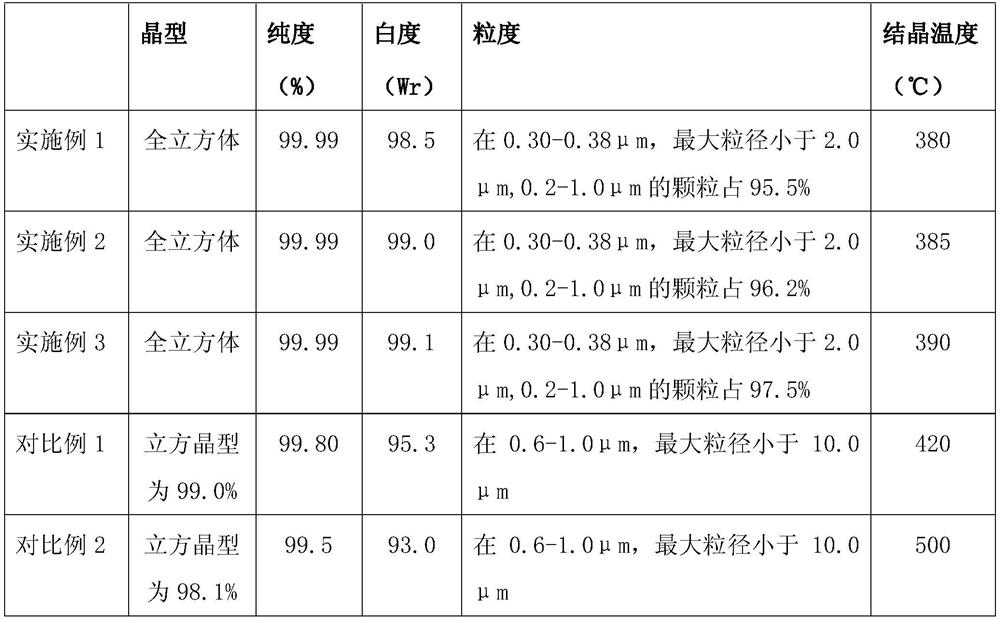

Examples

Embodiment 1

[0021] The oxygen-enriched production process of catalyst grade antimony trioxide comprises the following steps:

[0022] 1) Using natural gas as fuel, blowing oxygen-enriched air with 35% oxygen content into the combustion system as a combustion aid to supply heat to the antimony white furnace, the pressure of the oxygen-enriched air with 35% oxygen content is controlled at 10kPa, and the flow rate is 110m 3 / min, the temperature in the reaction zone of the antimony white furnace is raised to 700°C;

[0023] 2) When the temperature in the furnace reaction zone of the antimony white furnace rises to 700°C, put high-purity antimony with an antimony content of more than 99.9% into the furnace reaction zone of the antimony white furnace to melt it, and spray 35% oxygen content on the surface of the antimony liquid Oxygen-enriched air, the pressure of oxygen-enriched air with 35% oxygen content is controlled at 10kPa, and the flow rate is 80m 3 / min, make the antimony oxidation v...

Embodiment 2

[0027] The oxygen-enriched production process of catalyst grade antimony trioxide comprises the following steps:

[0028] 1) Using natural gas as fuel, blowing oxygen-enriched air with 25% oxygen content into the combustion system as a combustion aid to supply heat to the antimony white furnace, the pressure of the oxygen-enriched air with 25% oxygen content is controlled at 15kPa, and the flow rate is 120m 3 / min, the temperature in the reaction zone of the antimony white furnace is raised to 710°C;

[0029] 2) When the temperature in the furnace reaction zone of the antimony white furnace rises to 710°C, put high-purity antimony with an antimony content of more than 99.9% into the furnace reaction zone of the antimony white furnace to melt it, and spray 25% oxygen on the surface of the antimony liquid Oxygen-enriched air, the pressure of oxygen-enriched air with 25% oxygen content is controlled at 15kPa, and the flow rate is 20m 3 / min, make the antimony oxidation volatiliz...

Embodiment 3

[0033] The oxygen-enriched production process of catalyst grade antimony trioxide comprises the following steps:

[0034] 1) Using natural gas as fuel, blowing oxygen-enriched air with 30% oxygen content into the combustion system as a combustion aid to supply heat to the antimony white furnace, the pressure of the oxygen-enriched air with 30% oxygen content is controlled at 12kPa, and the flow rate is 130m 3 / min, the temperature in the reaction zone of the antimony white furnace is raised to 705°C;

[0035] 2) When the temperature in the furnace reaction zone of the antimony white furnace rises to 705°C, put high-purity antimony with an antimony content of more than 99.9% into the furnace reaction zone of the antimony white furnace to melt it, and spray 30% oxygen content on the surface of the antimony liquid Oxygen-enriched air, the pressure of oxygen-enriched air with 30% oxygen content is controlled at 12kPa, and the flow rate is 60m 3 / min, make the antimony oxidation v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com