Pure-phase spinel Co3O4 multistage nanosheet, soft template preparation method thereof and application thereof in supercapacitor

A technology of supercapacitors and nanosheets, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, cobalt oxide/cobalt hydroxide, etc. Green development of the surrounding environment and other issues, to achieve good industrial application prospects, large-scale production applications, and low costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

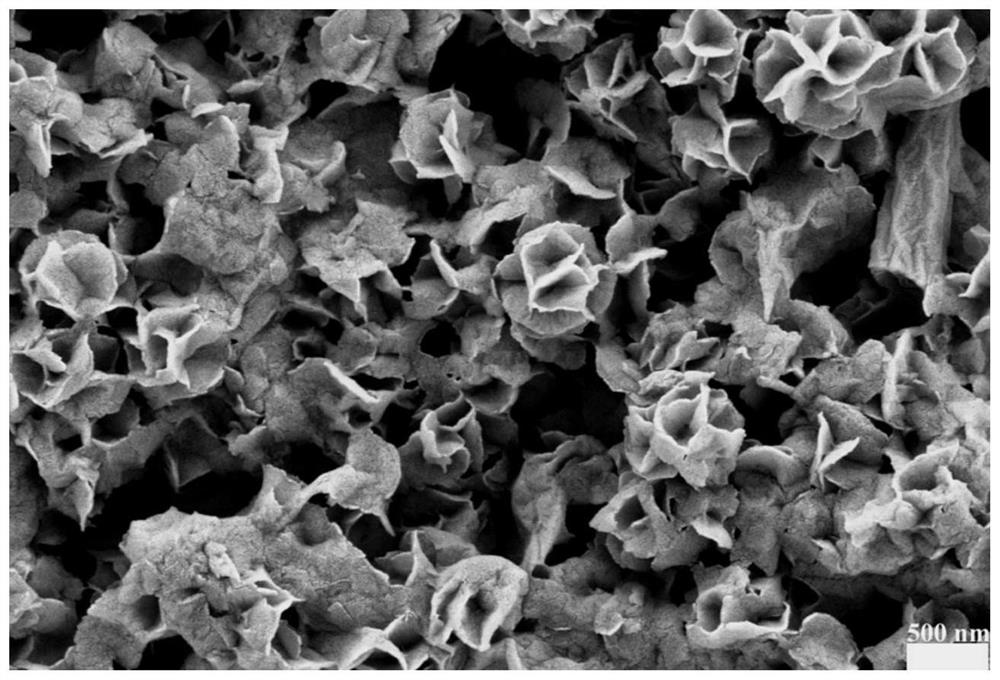

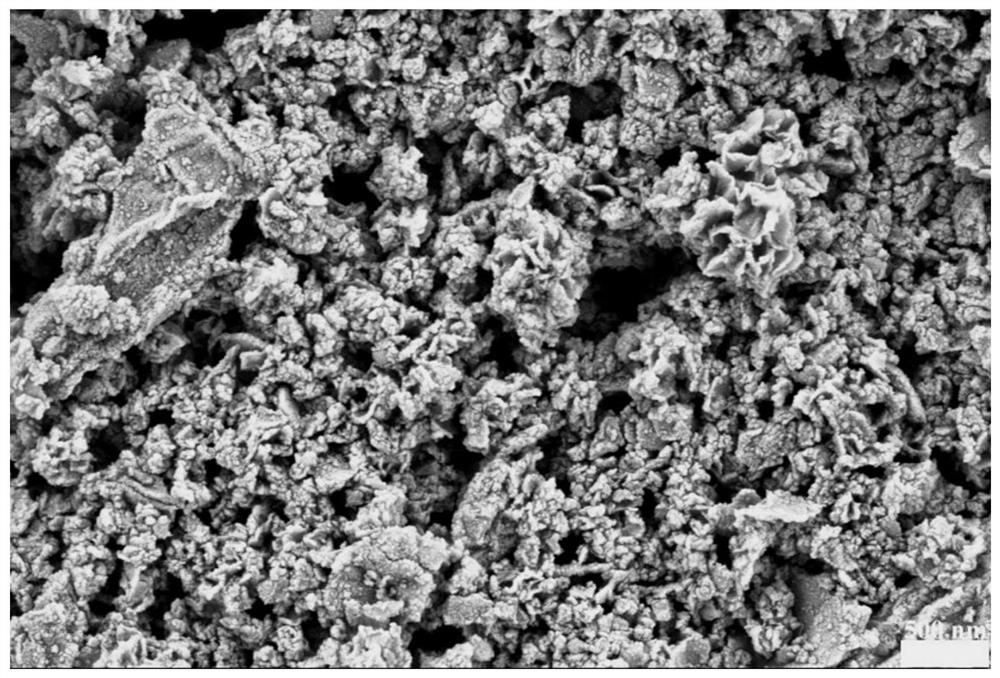

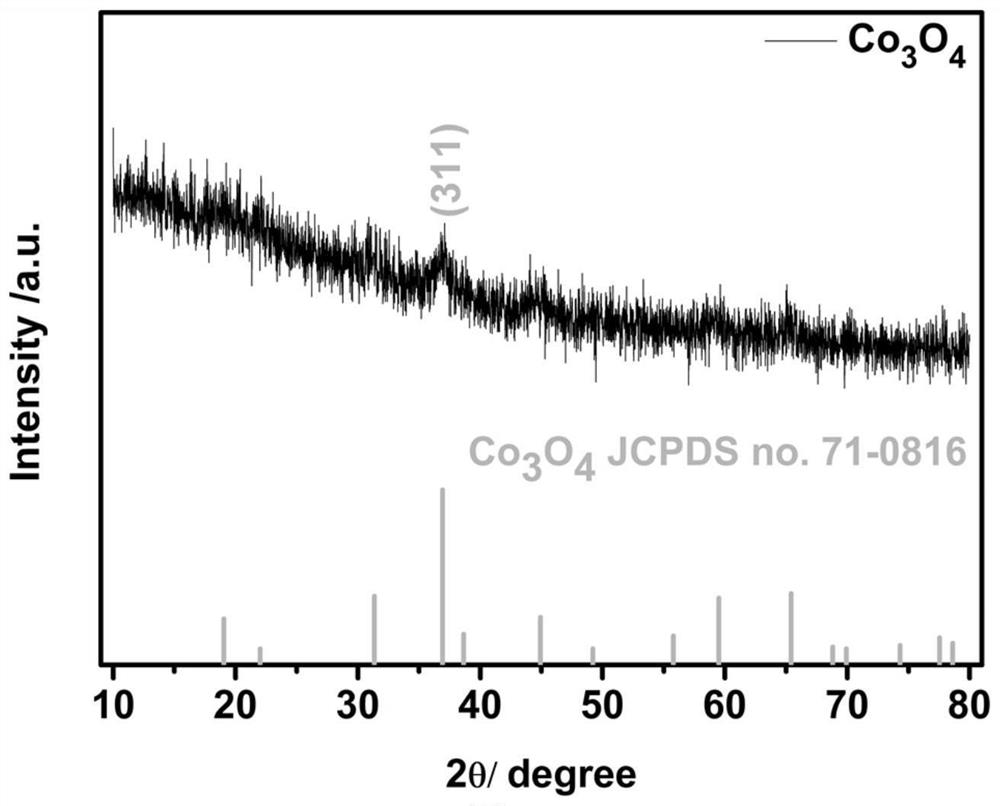

[0046] A kind of pure phase spinel Co of the present embodiment 3 o 4 A method for preparing a multi-level nanosheet soft template, the method specifically includes the following steps:

[0047] (1)Co 3 o 4 Preparation of Hierarchical Nanosheet Precursors

[0048] 0.5710g cobalt chloride hexahydrate (CoCl 2 ·6H 2 (2), 0.5043g urea, 3.4606g sodium dodecyl sulfate (SDS) add in the 500mL one-necked flask successively, pour 240mL deionized water into described flask again, flask is placed in oil bath, temperature is controlled at 120°C, reflux, stir and heat for 4 hours, the solution turns from pink to light blue, filter while hot after the reaction is complete, vacuum filter with a 0.22μm filter membrane, and then wash with hot water and hot ethanol to obtain a blue disc shaped solid, and dried in an oven at 60°C for 24 hours to obtain nanoflowers assembled in sheet form.

[0049] (2)Co 3 o 4 Preparation of Hierarchical Nanosheets

[0050] The Co obtained in step (1) 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com