Blue-green algae mud pressure filtrate treatment method

A treatment method, the technology of cyanobacteria mud, applied in the direction of sludge treatment, water/sludge/sewage treatment, sedimentation treatment, etc., can solve the huge fluctuations in water quality and water volume of the filter press, high organic content of the filter press, and the treatment effect of the denitrification process low cost, efficient treatment, and reduced biological inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

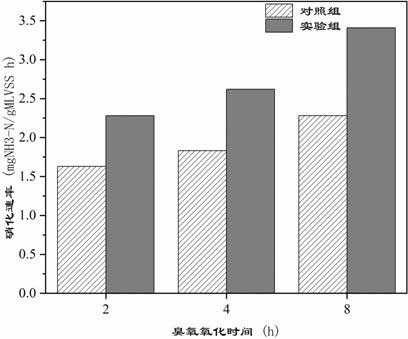

Examples

Embodiment 1

[0032] The cyanobacteria mud press filter in the following examples is prepared by the following method:

[0033] S1, cyanobacteria are salvaged to the algae water separation station for preliminary dehydration to obtain cyanobacteria mud with a moisture content of 85-95%;

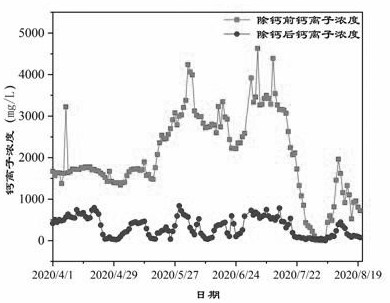

[0034] S2, the cyanobacteria mud with a water content of 85-95% is conditioned by adding medicaments, the medicaments include 30% calcium oxide and 5% ferric chloride on a dry basis of the cyanobacteria mud, and then enter the plate and frame filter press for dehydration to obtain Blue-green algae mud press filtrate and blue-green algae mud with a water content of 70%.

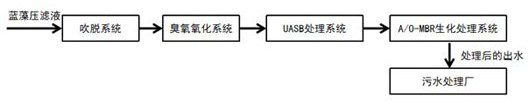

[0035] like image 3 Shown, a kind of blue-green algae mud pressing filtrate processing method comprises the following steps of carrying out successively:

[0036] S3: The cyanobacteria mud press filtrate is treated by the blow-off process, and the blow-off rate is 30 L / m 3 · min, stripping time 3 h;

[0037] S4: Add soluble carbonate ...

Embodiment 2

[0042] This example is an experiment of stripping and removing ammonia nitrogen. The stripping device has a height-to-diameter ratio of 6 / 1 and a volume of 2.3 L (liquid volume 2 L). An air pump is used to conduct a continuous flow stripping experiment with a residence time of 0.5 h. The experimental conditions as follows:

[0043] S1: Directly use cyanobacteria filtrate water to carry out continuous flow blow-off experiment, and the blow-off rate is 0, 5, 10, 20, 30, 45, L / m 3 Min;

[0044] S2: pH, initial ammonia nitrogen concentration, etc. all use the corresponding indicators of the actual press filtrate, and this experiment uses normal temperature air stripping;

[0045] S3: After the reactor runs stably, take samples at 0, 2.0, 2.5, and 3.0 hours respectively, and measure the ammonia nitrogen concentration index;

[0046] It can be seen from Table 1 below that the stripping rate in this experiment was 30 L / m 3 min, when the initial ammonia nitrogen concentration is 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com