Preparation method of isomaltitol

A technology of isomalt and isomaltulose, which is applied in the field of isomalt preparation, can solve the problems of difficult separation, waste, and increasing the amount of evaporation and concentration steam, so as to improve the product yield and simplify the production process , the effect of saving steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present embodiment is a kind of preparation method of isomalt, comprises the following steps:

[0036] (1) Isomaltulose is prepared by converting sucrose: the sucrose is prepared into a sucrose solution, the concentration of the sucrose solution is 45%, the pH value is adjusted to 6.5, the sucrose solution is added to the immobilized thallus with sucrose isomerase, and the immobilized The weight of the bacterium is 10% of the weight of the sucrose solution, the temperature is 28°C, and sterile compressed air is passed through, and the sucrose is converted into isomaltulose under the condition of a pressure of 0.05Mpa to obtain an isomaltulose solution;

[0037] The composition of the isomaltulose solution is: 79.5% isomaltulose, 14.7% trehalulose, 3.2% fructose, and 0.9% glucose.

[0038] (2) decolorizing, ion-exchanging and evaporating the isomaltulose liquid obtained in step (1) to obtain the purified isomaltulose liquid;

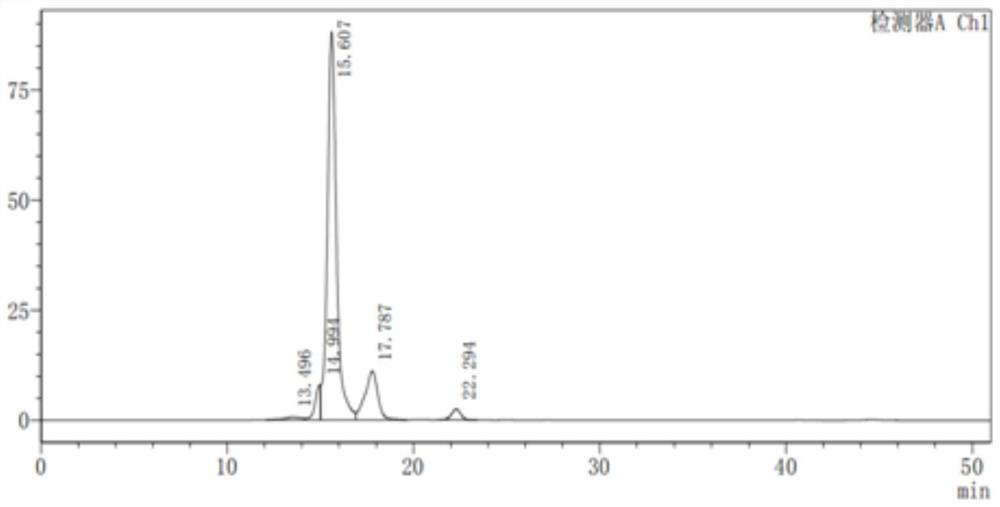

[0039] The composition of the isomaltul...

Embodiment 2

[0059] The present embodiment is a kind of preparation method of isomalt, comprises the following steps:

[0060] (1) Isomaltulose is prepared by converting sucrose: the sucrose is formulated into a sucrose solution, the concentration of the sucrose solution is 55%, the pH value is adjusted to 8.0, the sucrose solution is added to the immobilized thallus with sucrose isomerase, and the immobilized The weight of the bacterium is 12% of the weight of the sucrose solution, the temperature is 31°C, and sterile compressed air is passed through, and the sucrose is converted into isomaltulose under the condition of a pressure of 0.06Mpa to obtain an isomaltulose liquid;

[0061] The composition of the isomaltulose liquid is: isomaltulose 73.2%, trehalulose 17.4%, fructose 3.8%, glucose 1.7%.

[0062] (2) decolorizing, ion-exchanging and evaporating the isomaltulose liquid obtained in step (1) to obtain the purified isomaltulose liquid;

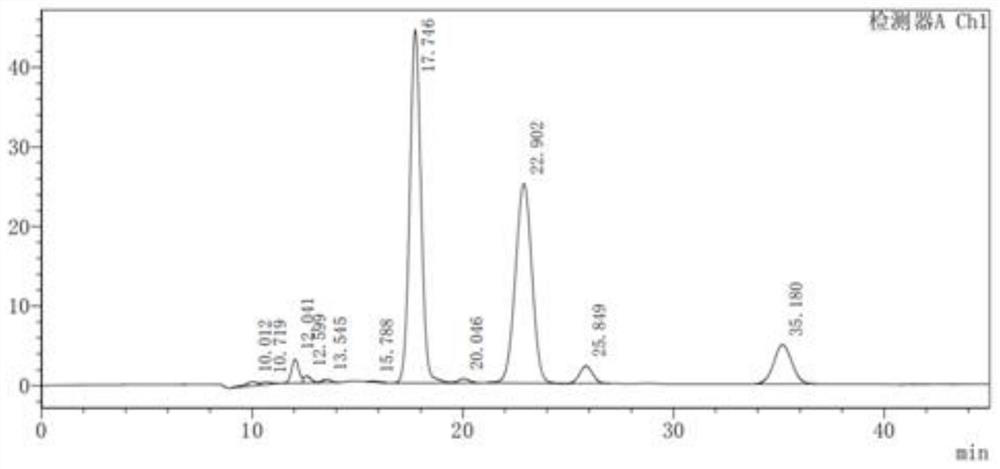

[0063] The composition of the isomaltulose pu...

Embodiment 3

[0078] The present embodiment is a kind of preparation method of isomalt, comprises the following steps:

[0079] (1) Preparation of isomaltulose by sucrose conversion: sucrose is prepared into sucrose solution, the concentration of sucrose solution is 20%, the pH value is adjusted to 5.0, the sucrose solution is added to the immobilized thallus with sucrose isomerase, and The weight of the bacteria is 8% of the weight of the sucrose solution, the temperature is 31° C., and sterile compressed air is passed through, and the sucrose is converted into isomaltulose under the condition of a pressure of 0.06Mpa to obtain an isomaltulose liquid;

[0080] The composition of the isomaltulose solution is: 78.5% isomaltulose, 16.7% trehalulose, 2.9% fructose, and 1.1% glucose.

[0081] (2) decolorizing, ion-exchanging and evaporating the isomaltulose liquid obtained in step (1) to obtain the purified isomaltulose liquid;

[0082] The composition of the isomaltulose purification liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com