TPEE composite material suitable for high-speed extrusion and preparation method thereof

A high-speed extrusion and composite material technology, applied in the field of polymer composite materials, can solve problems such as melt instability, high efficiency, and unsatisfactory production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention is applicable to the preparation method of the TPEE composite material of high-speed extrusion and comprises the steps:

[0055] (1) Put all raw material components into a high-speed mixer and mix uniformly by mass percentage to obtain a compound;

[0056] (2) Put the mixed material into a twin-screw extruder, the temperature of each section of the screw is 190-240°C, the screw speed is 350-420r / min, extrude and granulate, and obtain the PTEE composite material.

Embodiment 1-5

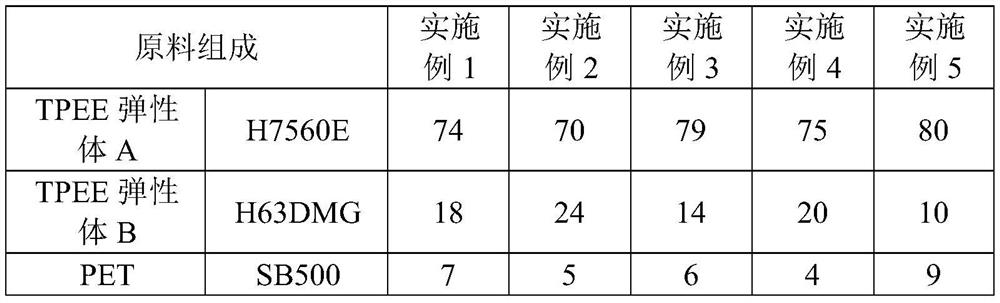

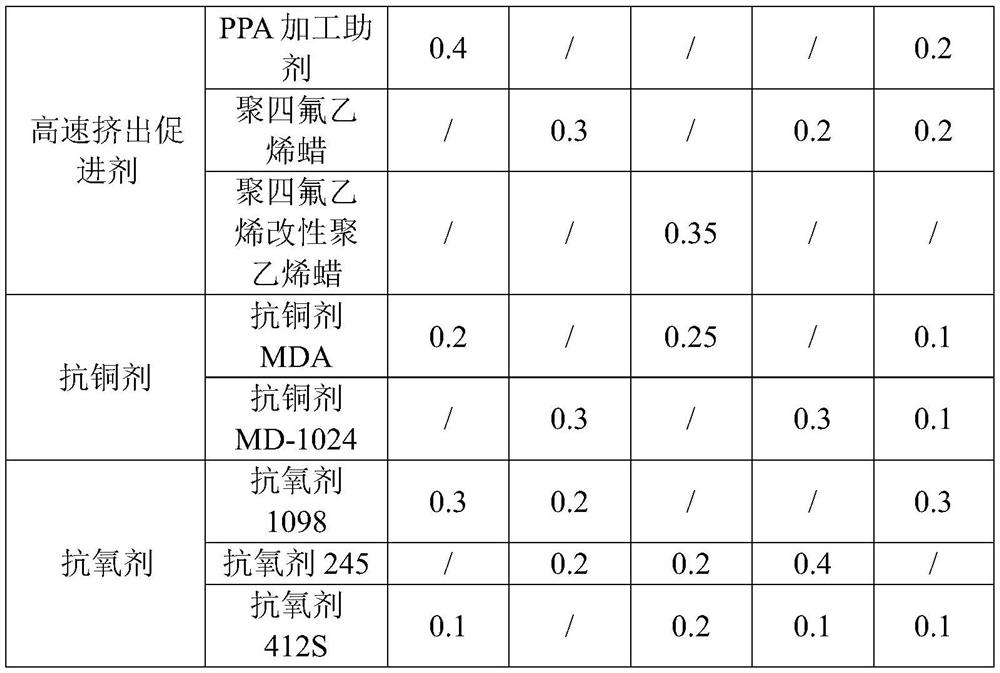

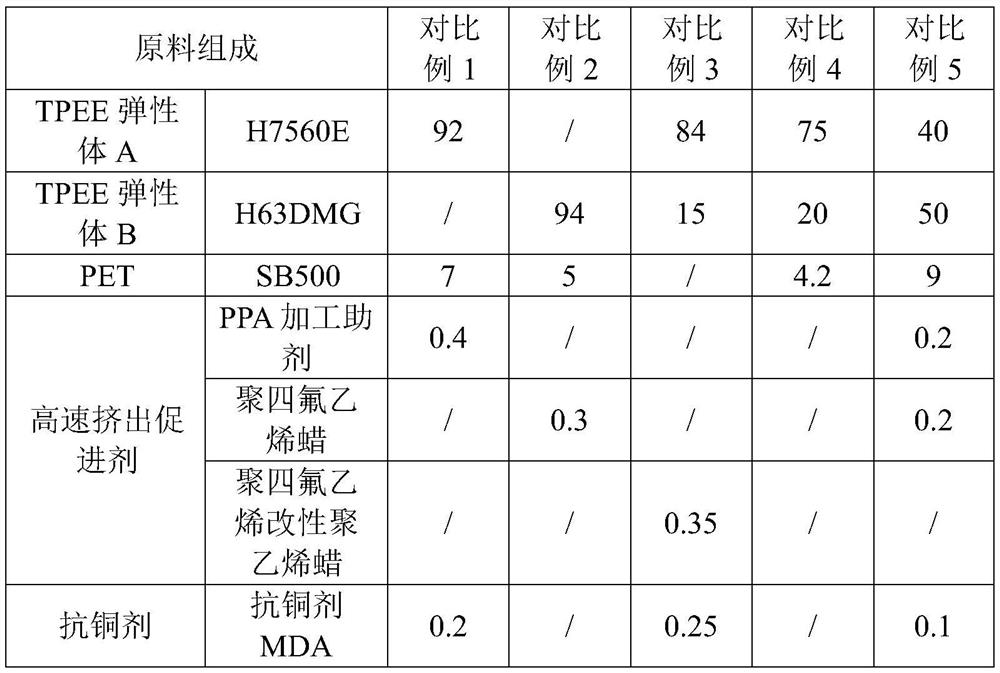

[0058] The mass percentages of the raw material components of the TPEE composite material suitable for high-speed extrusion provided by Examples 1-5 are shown in Table 1, wherein, TPEE elastomer A Sichuan is H7560E of Chenguang Chemical Research Institute; TPEE elastomer B is Jiangyin Hechuang H63DMG from Elastomer New Material Technology Co., Ltd.; PET is SB500 from Sinopec Yizheng Chemical Fiber Co., Ltd.; other additives are conventional materials on the market.

[0059] The TPEE composite material among the embodiment 1-5 is made by following method:

[0060] (1) Put all raw material components into a high-speed mixer and mix uniformly by mass percentage to obtain a compound;

[0061] (2) Put the mixture into a twin-screw extruder, set the temperature of each section of the screw to 238° C., and the screw speed to 400 r / min, extrude and granulate to obtain a PTEE composite material.

[0062] The TPEE composite raw material composition mass percent (%) of table 1 embodimen...

Embodiment 6

[0066] Embodiment 6 provides a TPEE composite material suitable for high-speed extrusion. The difference from Embodiment 1 is that the PPA processing aid is replaced by vinyl silicone oil, and the rest of the raw material composition and process conditions are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wire diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com