Method for reducing content of fructan in rice and flour food by microwave curing

A technology of microwave ripening and fructan, which is applied in the field of food processing, can solve the problems of not being suitable for rice noodle food processing, affecting product texture, prolonging fermentation time, etc., achieving short production time, shortening production time, and accelerating ripening The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

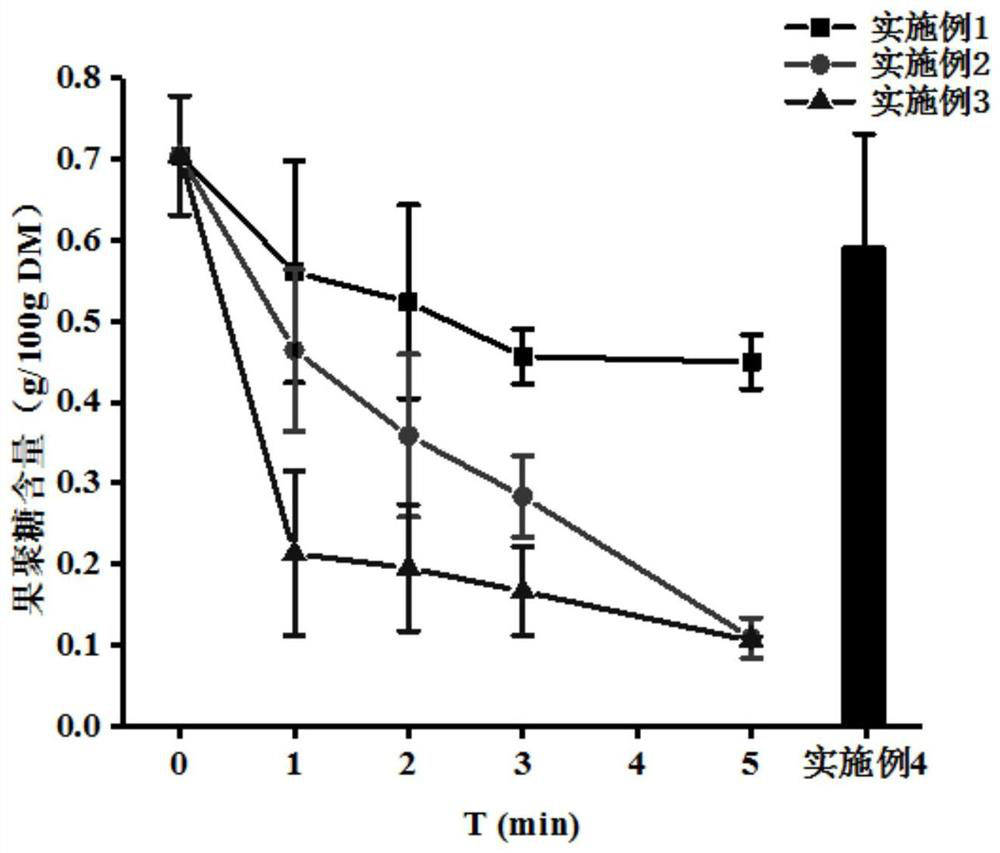

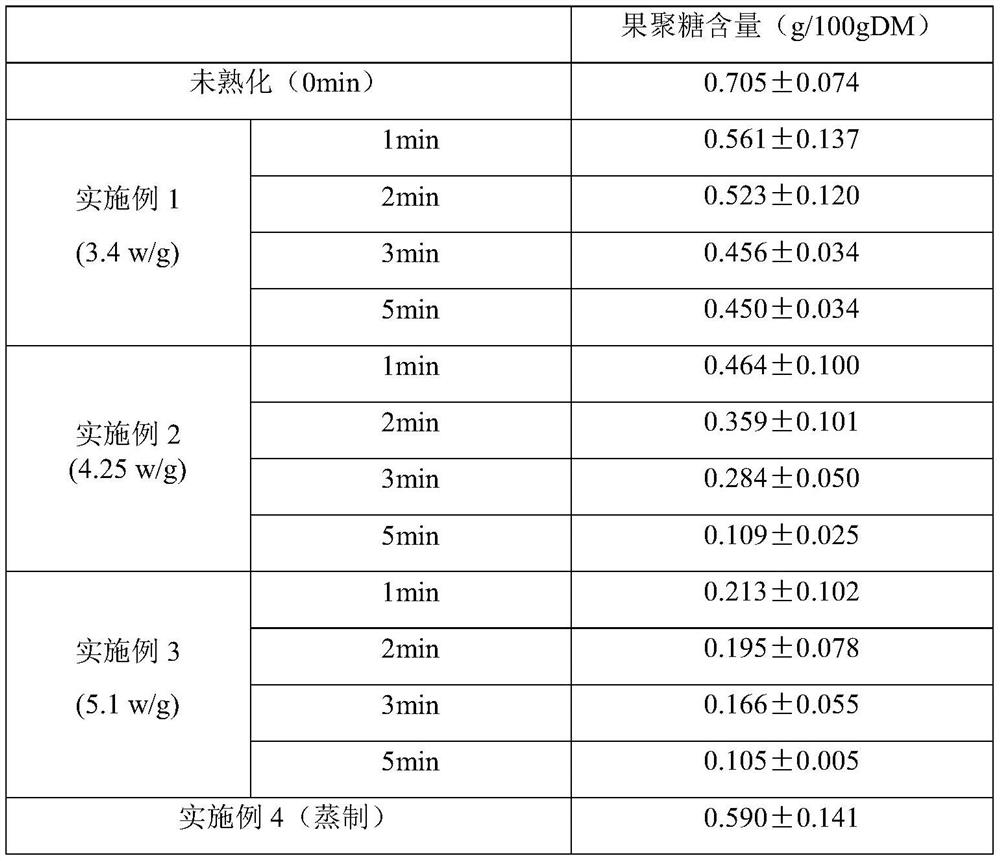

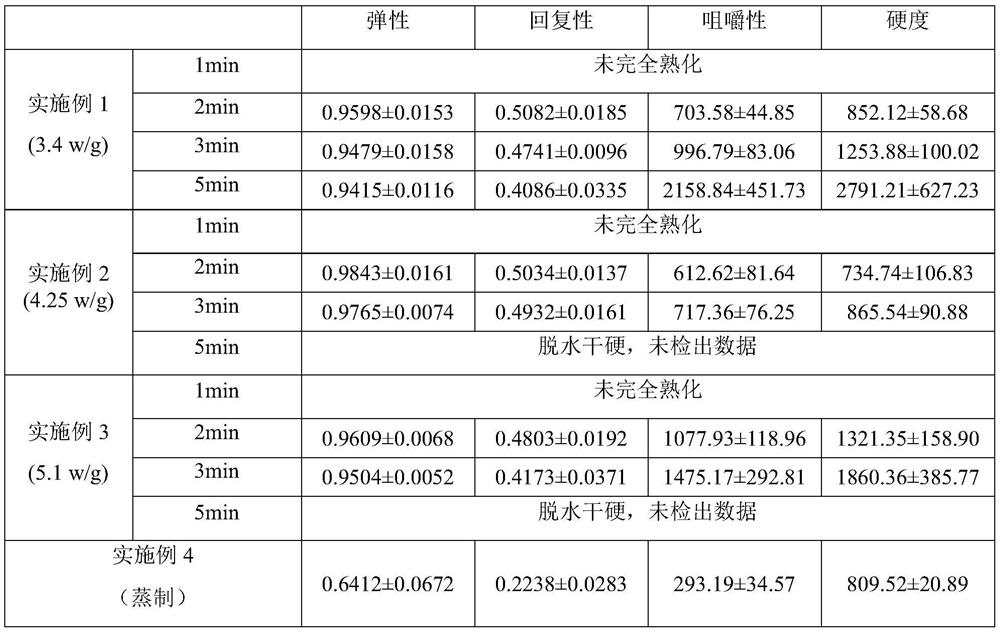

[0035] Example 1: The specific implementation steps of the microwave-cooked hair cake prepared by fermentation with commercially available Angel high-activity dry yeast (golden pack) starter are as follows:

[0036] (1) Prepare hair cake slurry:

[0037] Weigh 200 parts of wheat flour, 2.4 parts of active dry yeast, and 1 part of baking powder according to parts by weight, put them in the mixing tank and mix them evenly at low speed, then add 140 parts of warm water, and stir in the mixing tank at low speed until it becomes sticky , and then stirred at a high speed for 12 minutes to obtain a slurry for making cakes;

[0038] (2) Proofing and ripening of the cake slurry:

[0039] Weigh 100 g of the slurry for making hair cake obtained in step (1), place it in a mold, vibrate and exhaust it, and proof it for 40 minutes at a temperature of 37° C. and a humidity of 85%. Place the proofed cake slurry in a microwave tunnel heating device, set the microwave power to 3.4w / g, take di...

Embodiment 2

[0040] Example 2: Microwave-cooked hair cake prepared by fermentation with commercially available Angel high-activity dry yeast (golden pack) starter

[0041] The specific implementation steps are as follows:

[0042] (1) Prepare hair cake slurry:

[0043] Weigh 200 parts of wheat flour, 2.4 parts of active dry yeast, and 1 part of baking powder according to parts by weight, put them in a mixing tank and mix them evenly at a low speed, then add 140 parts of warm water, and stir in a mixing tank at a low speed until viscosity is formed. Then stir at high speed for 12 minutes to obtain a slurry for making cakes;

[0044] (2) Proofing and ripening of the cake slurry:

[0045]Weigh 100 g of the slurry for making hair cake obtained in step (1), place it in a mold, vibrate and exhaust it, and proof it for 40 minutes at a temperature of 37° C. and a humidity of 85%. Put the proofed cake slurry in a microwave tunnel heating device, set the microwave power to 4.25w / g, take different...

Embodiment 3

[0046] Example 3: Microwave-cooked hair cake prepared by fermentation with commercially available Angel high-activity dry yeast (golden pack) starter

[0047] The specific implementation steps are as follows:

[0048] (1) Prepare hair cake slurry:

[0049] Weigh 200 parts of wheat flour, 2.4 parts of active dry yeast, and 1 part of baking powder according to parts by weight, put them in a mixing tank and mix them evenly at a low speed, then add 140 parts of warm water, and stir in a mixing tank at a low speed until viscosity is formed. Then stir at high speed for 12 minutes to obtain a slurry for making cakes;

[0050] (2) Proofing and ripening of the cake slurry:

[0051] Weigh 100 g of the slurry for making hair cake obtained in step (1), place it in a mold, vibrate and exhaust it, and proof it for 40 minutes at a temperature of 37° C. and a humidity of 85%. Place the proofed cake slurry in a microwave tunnel heating device, set the microwave power to 5.1w / g, take differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com