Phosphorus and nitrogen co-doped iron monatomic carbon material as well as preparation method and application thereof

An atomic carbon and co-doping technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of limiting the large-scale use of noble metal single-atom catalysts, the reduction of catalyst activity and stability, and the high cost of noble metals. Achieve the effects of good battery power density, improved catalytic activity and stability, and improved catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

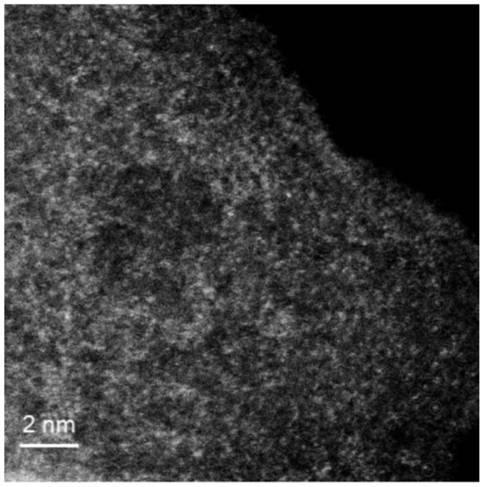

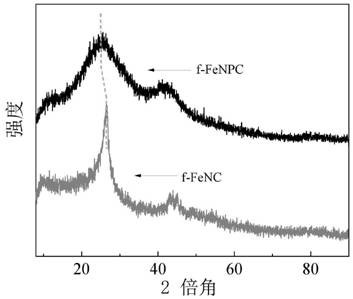

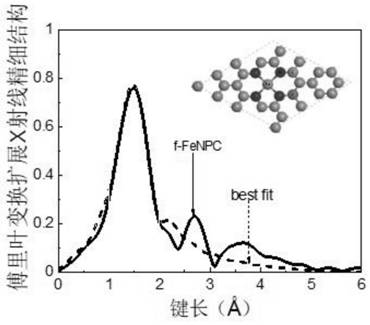

[0050] refer to figure 1 The flow chart of the preparation process is shown to illustrate the method of the present invention in detail.

[0051]Firstly, using formamide as nitrogen source and carbon source, adding the selected iron salt and zinc salt into formamide, and adding red phosphorus, sonicating until dissolved, and obtaining the hydrothermal reaction mother liquid. Wherein the iron salt is selected from anhydrous ferric chloride, and the zinc salt is selected from anhydrous zinc chloride, this is mainly because the self-polymerization of formamide cannot take place in the presence of water.

[0052] The purpose of adding zinc salt is to prevent metal elements from agglomerating. The added amount of the iron salt and the zinc salt is added in a ratio of 1 / 10 under the condition that a large amount of metal aggregates are not synthesized. Wherein said phosphorus powder selects red phosphorus, and its addition amount is equal to the molar concentration of iron salt. ...

Embodiment 2

[0056] This embodiment 2 provides a specific preparation method of nitrogen and phosphorus co-doped iron single-atom carbon material:

[0057] a: Take 30mL of formamide, add 0.04g of anhydrous ferric chloride, 0.204g of anhydrous zinc chloride and 0.0046g of red phosphorus into it, stir thoroughly and ultrasonically until dissolved.

[0058] b: transfer the solution obtained in a to a closed hydrothermal reactor, raise the temperature to 180° C., and react for 12 hours. After cooling, wash with water and ethanol three times respectively, and dry to obtain a solid material that successfully incorporates phosphorus and contains iron and zinc atoms.

[0059] c: Put the solid product obtained in b into a porcelain boat, and raise the temperature to 900°C at a rate of 5°C / min. At this temperature, react for 2 hours, and the zinc atoms will sublimate. After natural cooling, put the product at 80°C with The concentrated sulfuric acid oil bath was used for 6 hours to remove the iron ...

Embodiment 3

[0084] The nitrogen and phosphorus co-doped iron single-atom carbon material prepared in Example 2 was used for the preparation of a rotating disk electrode. The preparation method was as follows: take 5 mg of the catalyst material prepared in Example 2 and disperse it in 490 μ L DMF, add 10 μ L polytetrafluoroethylene Vinyl fluoride solution (20%, Aladdin's reagent), mix well, ultrasonic 30min. 10 μL of the prepared active material solution was evenly dropped on the glassy carbon electrode. The active material solution was dripped and dried before testing.

[0085] In addition, the nitrogen-doped iron single-atom carbon material prepared in Comparative Example 1 was used to prepare a rotating disk electrode, and the preparation method was as above.

[0086] Performance testing: test the CV and LSV polarization curves in 0.1M perchloric acid and 0.1M phosphoric acid solutions with the two electrodes prepared in Example 3 above and commercially available platinum carbon electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com