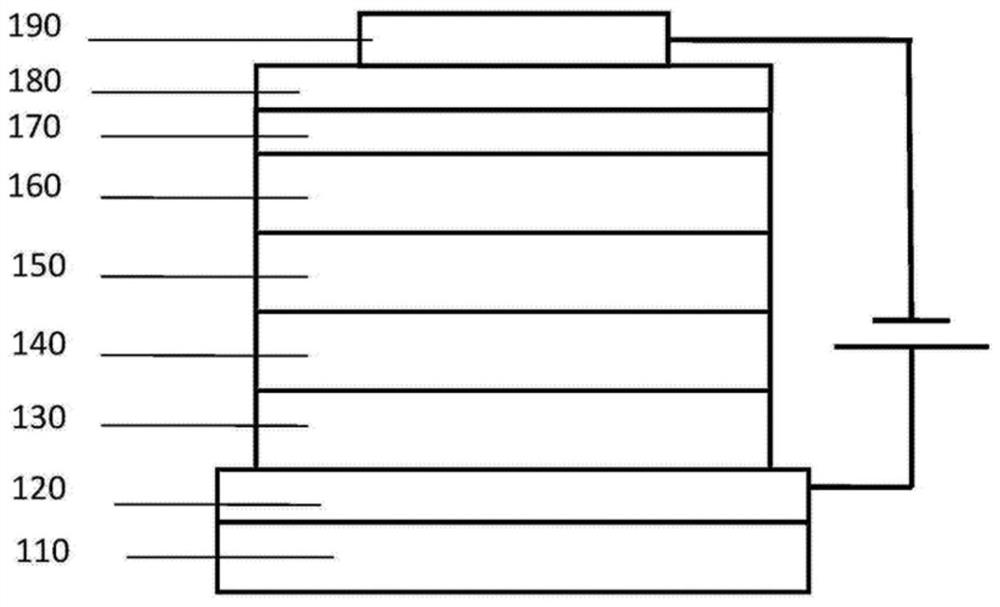

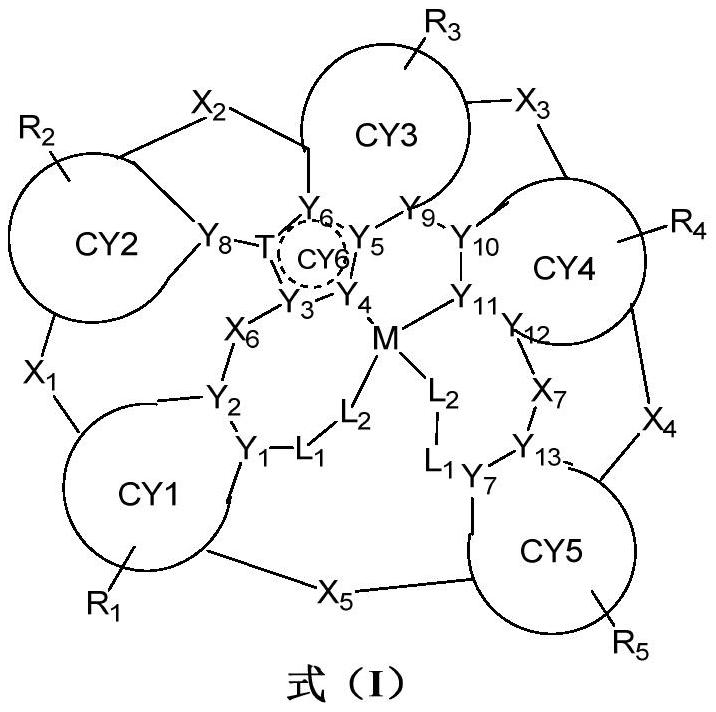

Organometallic complex and organic photoelectric element containing same

An organometallic and complex technology, applied in platinum group organic compounds, platinum group organic compounds, electrical components, etc., can solve the problems of expensive iridium metal and insufficient crustal content, and achieve excellent luminescence performance, reduced lighting voltage, high Effect of Luminous Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

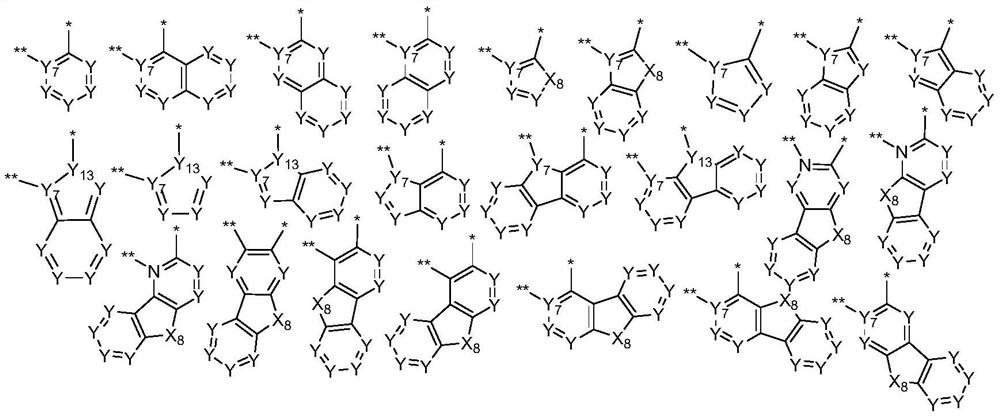

Method used

Image

Examples

Embodiment 1

[0110] Embodiment 1: the synthesis of compound 1

[0111]

[0112] (1) Under a nitrogen atmosphere, S-1 (10 mmol) and S-2 (11 mmol) were completely dissolved in tetrahydrofuran / water (2:1, 80 ml) in a round bottom flask, and potassium carbonate ( 5 g), tetrakis(triphenylphosphine) palladium acetate (0.1 g), and the mixture was heated to reflux for 10-12 hours. After cooling down to room temperature, add acetic acid (2 ml) and stir for 1 hour, separate the upper tetrahydrofuran layer, filter it with diatomaceous earth, concentrate the solvent in vacuo, and use petroleum ether:ethyl acetate (20:1~2:1) as The eluent was purified and separated on a silica gel column to obtain S-3 (yield 82%), LC-MS, 692.4.

[0113] (2) Under nitrogen atmosphere, S-1 (10 mmol), nickel chloride (10 mmol), and acetic acid (8 ml) were heated under reflux in a round bottom flask for 3 days. After cooling down to room temperature, a yellow solid was obtained by filtration, and purified and separate...

Embodiment 2

[0114] Embodiment 2: the synthesis of compound 2

[0115]

[0116] The synthesis steps of compound 2 are similar to compound 1, and the yield of the final metal complex is 76%. LC-MS: theoretical 941.37, measured: 941.3; elemental analysis C: 66.31; H: 5.46; N: 2.97; measured: C :66.26; H:5.48; N:3.02.

Embodiment 3

[0117] Embodiment 3: the synthesis of compound 3

[0118]

[0119]The synthesis steps of compound 3 are similar to those of compound 1, and the yield of the final metal complex is 75%. LC-MS: theoretical 944.36, measured: 944.4; elemental analysis C: 66.09; H: 5.44; N: 4.45; measured: C :66.12; H:5.48; N:4.56.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com