A kind of mofs material that adsorbs and separates rhenium or technetium and its preparation method and application

An adsorption separation and reaction technology, applied in chemical instruments and methods, other chemical processes, organic chemistry, etc., can solve the problems of slow adsorption kinetics, poor adsorption selectivity, and low adsorption capacity, and achieve good stability and high adsorption performance. , strong selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

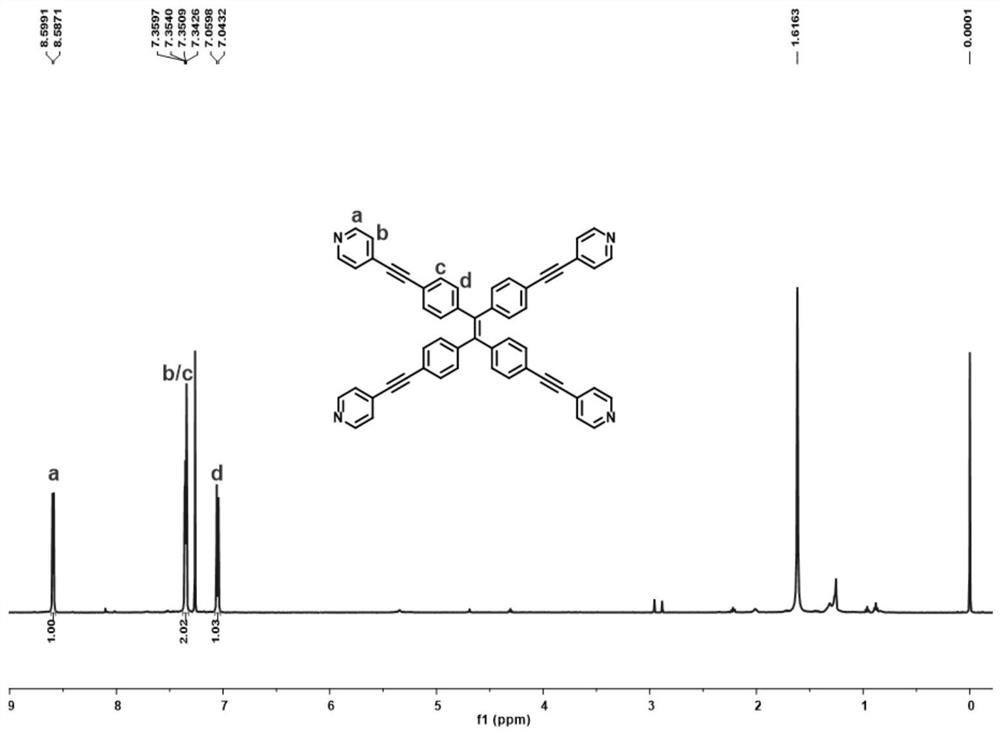

Embodiment 1

[0045] (1) Weigh 1.2g of tetrabromotetraphenylethylene, 8.7mg of cuprous iodide, and 64.7mg of bis(triphenylphosphine)palladium dichloride in 70mL of mixed solvent (THF / Et 3 N, 1 / 1) to start stirring, and feed argon gas at 60°C to start bubbling to remove the oxygen in the reaction system, add 1.7g trimethylethynyl silicon to it after 1h for reaction; after 12h, the reaction is complete, and the The reaction solution was removed by distillation under pressure, followed by dichloromethane extraction, anhydrous Na 2 SO 4 Drying, distilling off the solvent under reduced pressure, and then separating and purifying by column chromatography yielded 1.2 g of intermediate A with a yield of 90.2%; the reaction equation is as follows:

[0046]

[0047] (2) The obtained intermediate A was dissolved with 50 mL of dichloromethane, and 30 mL of methanol solution containing 0.54 g of sodium hydroxide was added thereto, stirred overnight, followed by extraction with dichloromethane, anhyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com