Polyimide film as well as preparation method and application thereof

A technology of polyimide film and polyamic acid, which is applied in the field of polymer materials and high-frequency polyimide film, can solve the problem of poor water absorption, dielectric constant and dielectric loss limitation of polyimide, and reduce Imide group concentration and other issues, to achieve the effect of increasing flexibility and regularity, low dielectric properties, good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

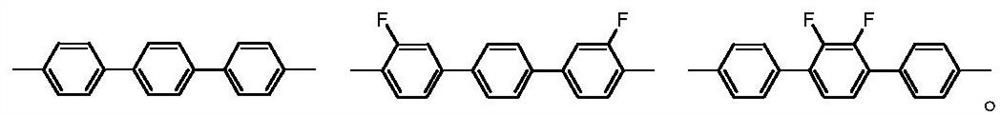

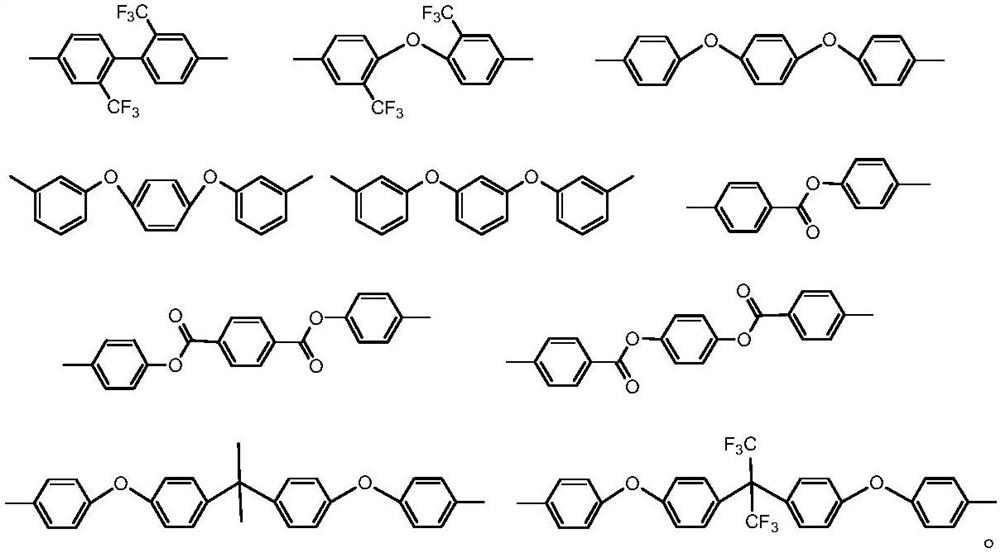

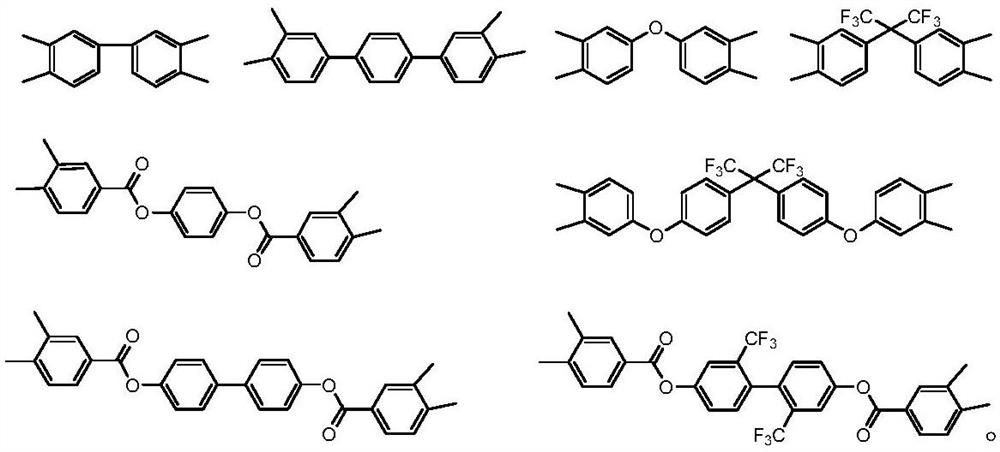

Method used

Image

Examples

Embodiment 1

[0078] Exhaust the reaction vessel with nitrogen in advance, after 30min, add 165.39g N,N-dimethylacetamide (DMAc, remove water with molecular sieve 24h in advance), then add 9.76g (37.5mmol) compound DATP and 2.16g (4.2mmol) compound HFBAPP, stirred at 25°C until completely dissolved; then gradually added 6.13g (20.8mmol) compound BPDA and 11.13g (20.8mmol) compound TABP, and stirred at room temperature for 12h to obtain 15wt% polyimide acid solution.

[0079] After the reaction is over, add acetic anhydride and isoquinoline in equimolar amounts of carboxylic acid groups respectively, add DMAc that has been dehydrated, and adjust to a solution of 10 to 13 wt %; the obtained polyimide acid solution is coated on the On the glass substrate, it was pre-dried at 80°C for 20 minutes, then transferred to the needle plate, and then transferred to the oven, and heat-treated at 150°C / 250°C / 300°C / 350°C for 30 minutes respectively, and thermal imidization was carried out, so as to produc...

Embodiment 2

[0081] Exhaust the reaction vessel with nitrogen in advance. After 30 minutes, add 143.40g of N,N-dimethylacetamide (DMAc, remove water with molecular sieve 24h in advance), and then add 0.98g (3.8mmol) of the compound DATP, 1.94g (3.8mmol) compound HFBAPP and 6.85g (30.0mmol) compound APAB, stirred at 25°C until completely dissolved; then gradually added 5.52g (18.8mmol) compound BPDA and 10.02g (18.8mmol) compound TABP, stirred at room temperature for 12h, Thus, a 15 wt% polyimide acid solution was obtained.

[0082] After the reaction, the obtained polyimide acid solution was coated on the glass substrate with a scraper, pre-dried at 80°C for 30 minutes, then transferred to the needle plate, and then transferred to the oven, respectively, at 150°C / 250°C Heat treatment at 300° C. / 350° C. for 30 minutes for thermal imidization, thereby preparing a polyimide film with a thickness of about 25 μm.

Embodiment 3~15 and comparative example 1~5

[0084] Replace the diamine and dianhydride with the ratios shown in the following Table 1 and Table 2 to carry out resin polymerization respectively, and keep warm at 25-100°C for 1h-12h polymerization to obtain polyamic acid with a solid content of 10-30% solution;

[0085] Then, in the same manner as in Example 1, a 25 μm thick polyimide film was prepared.

[0086] For the polyimide films obtained in Examples and Comparative Examples, the properties of the prepared polyimide films were measured according to the methods described below, and the results are summarized in Table 1 and Table 2.

[0087] (1) Mechanical properties (tensile strength, elongation at break and modulus of elasticity)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com