Binder for resin composite material and preparation method of binder

A technology of resin composite materials and adhesives, applied in the direction of grafted polymer adhesives, adhesives, adhesive types, etc., can solve the problems of easy peeling and delamination, poor bonding strength, etc., and achieve the effect of improving adsorption performance , increase flexibility, improve the effect of molecular weight and adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

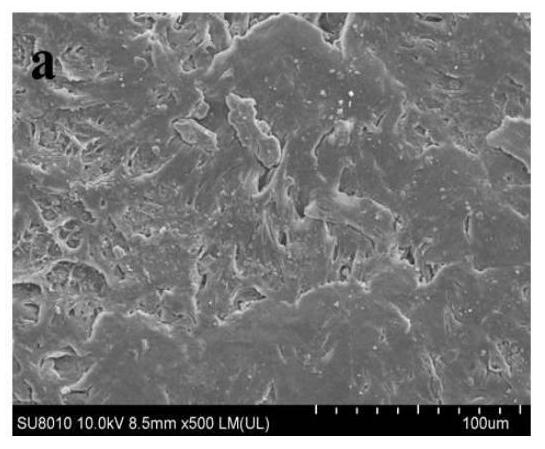

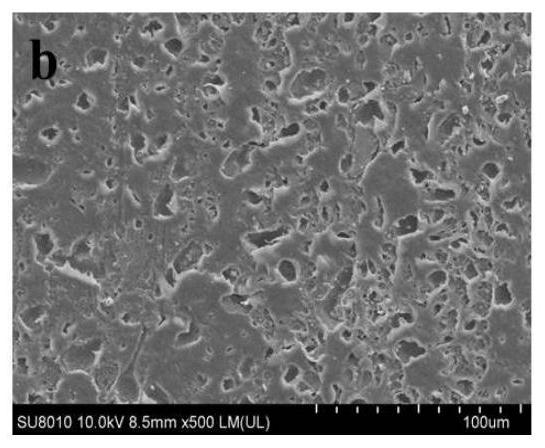

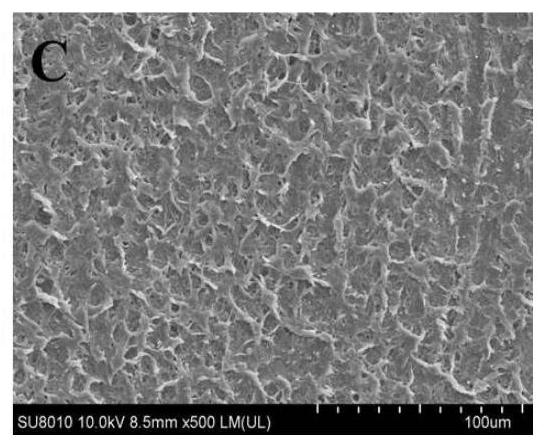

Image

Examples

preparation example Construction

[0032] The preparation method of the binder for the resin composite material comprises the following steps:

[0033] Step 1: Add 20.8-22.7 parts of phenolic alcohol head and 0.8-1.6 parts of catalyst into a high-pressure reactor equipped with a stirrer and a thermometer. After nitrogen replacement for 3 times, start vacuuming to gauge pressure -0.15MPa, and then heat up to 130- Dehydration starts at 135°C for 1-2 hours, and the constant temperature is around 125°C. Start to feed the cyclic monomer into the reactor, and feed 291.6-311.4 parts of the cyclic monomer into the reactor, and control the pressure to be less than 0.45MPa. After the passage, keep the temperature at 125-140°C for aging to negative pressure, cool down and discharge, The prepared polyether was obtained.

[0034]Step 2: Add the finished polyether into the reaction kettle, and heat up to 65-80°C by using a water bath. Prepare 6.1-8.3 parts of reducing agent, 4.7-6.5 parts of chain transfer agent, 137.8-145...

Embodiment 1

[0036] A binder for resin composite materials, which is formed by polymerizing the following components, the total mass of raw materials is 1000 parts, and each component includes: 21.5 parts of 2-methoxy-6-(2-propenyl)-phenol , 305 parts of propylene oxide, 1.2 parts of boron trifluoride, 140 parts of poly-1,2-propylene glycol, 7.0 parts of a composition of sodium dithionite and sodium metabisulfite with a mass ratio of 1:1, 6.2 parts of ammonium persulfate, mercaptopropyl 3.3 parts of acid, 26.5 parts of 3-(methacryloyloxy)propyltrimethoxysilane, 9.5 parts of diethanolamine, and the rest is water, with a total mass of 1000 parts.

[0037] The preparation method of the binder for the resin composite material comprises the following steps:

[0038] Step 1: Add 21.5 parts of 2-methoxy-6-(2-propenyl)-phenol and 1.2 parts of boron trifluoride into a high-pressure reactor equipped with a stirrer and a thermometer, and start vacuuming after nitrogen replacement for 3 times To the ...

Embodiment 2-6

[0040] Examples 2-6: According to the method of the present invention, according to the raw material composition and step parameters in Tables 1 and 2, binders for resin composite materials were prepared.

[0041] Table 1

[0042]

[0043]

[0044] Table 2

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com