A kind of preparation method of biomass-based temperature control material and the temperature control material prepared

A biomass and porous material technology, applied in the field of new energy materials, can solve the problems of complex production process, high melting point and high cost, and achieve the effect of simple preparation process, wide source of raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

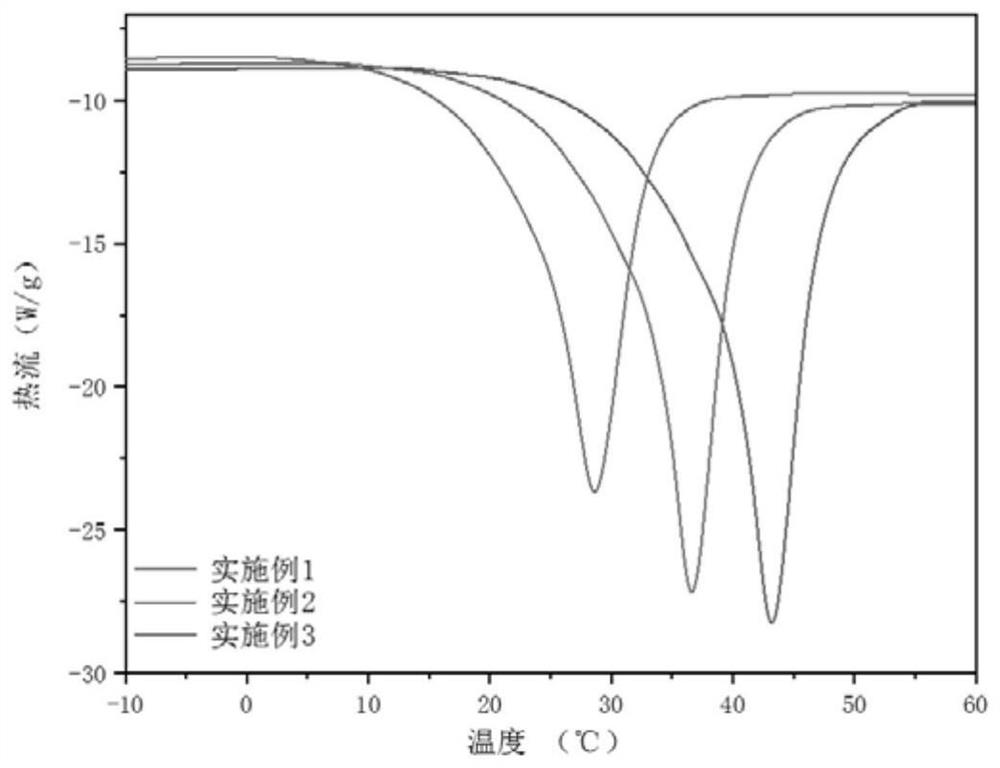

Embodiment 1

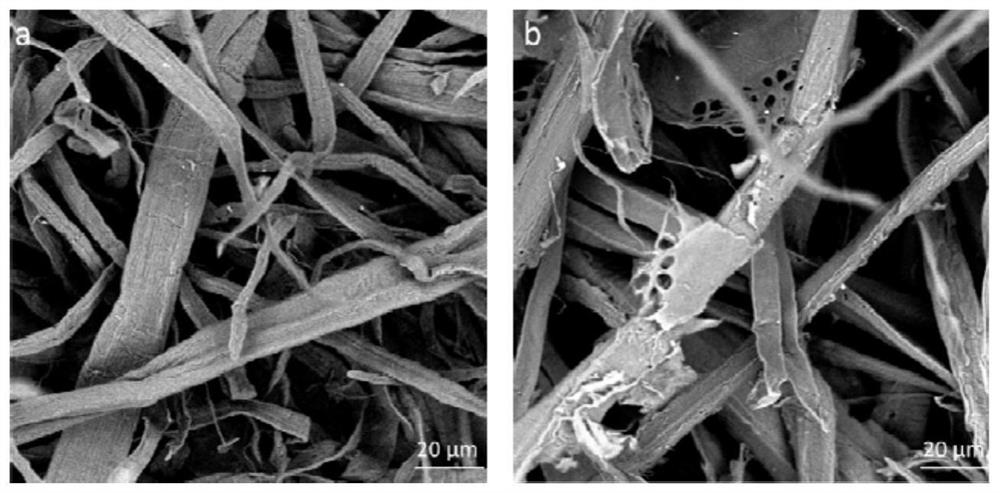

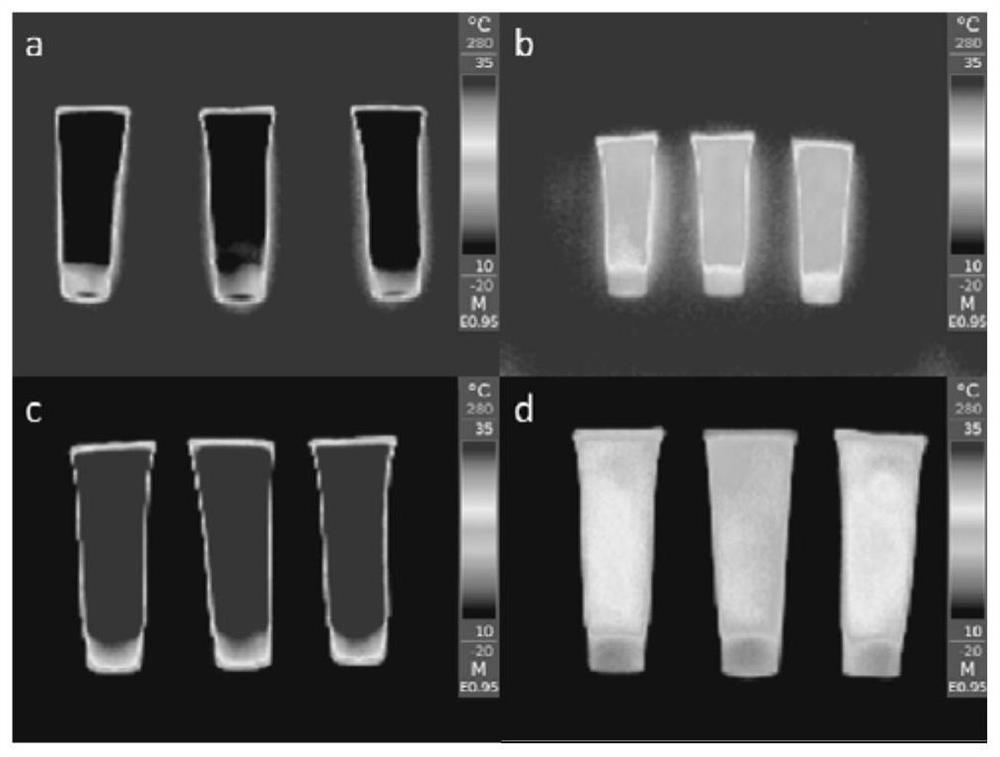

[0028] Add 5 parts of poplar pulp, 5 parts of sodium periodate, and 85 parts of water into the reaction kettle, stir at room temperature for 1 hour, and then fully wash to obtain poplar pulp oxidized by sodium periodate.

[0029] Add 5 parts of oxidized poplar pulp, 90 parts of coconut wax and 5 parts of linseed oil into the reaction kettle at 50°C, start stirring, set the stirring speed at 200 r / min, and convey the mixed slurry after stirring for 60 min Go to the filling machine for filling, and the quality of each product is 100 grams. According to the design amount of 5 kg per square meter, it is installed on the inner wall of the building. When the ambient temperature in a certain place is 10-35 ℃, the temperature control range: 18-30 ℃, the energy saving rate is 35%, and the service life is 5 years.

Embodiment 2

[0031] Add 5 parts of poplar pulp, 15 parts of potassium periodate, and 85 parts of water into the reaction kettle, stir at room temperature for 1 hour, and then fully wash to obtain poplar pulp oxidized by sodium periodate.

[0032] Add 10 parts of oxidized poplar pulp, 80 parts of coconut wax and 10 parts of linseed oil into the reaction kettle at 50°C, start stirring, set the stirring speed at 200 r / min, and transfer the mixed slurry after stirring for 60 min Go to the filling machine for filling, and the quality of each product is 100 grams. According to the design amount of 5 kg per square meter, it is installed on the inner wall of the building. When the ambient temperature in a certain place is 10-35°C, the temperature control range is 16-28°C, the energy saving rate is 30%, and the service life is 10 years.

Embodiment 3

[0034] Add 5 parts of poplar pulp, 10 parts of sodium periodate, and 85 parts of water into the reaction kettle, stir at room temperature for 1 hour, and then fully wash to obtain poplar pulp oxidized by sodium periodate.

[0035] Add 20 parts of oxidized poplar pulp, 70 parts of coconut wax and 10 parts of linseed oil into the reaction kettle at 50°C, start stirring, set the stirring speed at 200 r / min, and transfer the mixed slurry after stirring for 60 min Go to the filling machine for filling, and the quality of each product is 100 grams. According to the design amount of 5 kg per square meter, it is installed on the inner wall of the building. When the ambient temperature in a certain place is 10-35°C, the temperature control range is 16-28°C, the energy saving rate is 30%, and the service life is 15 years.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com