Polarization-independent electro-optical modulator based on two-dimensional grating coupling

An electro-optic modulator and two-dimensional grating technology, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of single channel, increase the cost of chip packaging, and cannot realize the modulation of light intensity, etc., achieve high coupling efficiency and improve microwave loss, effect of good impedance matching design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

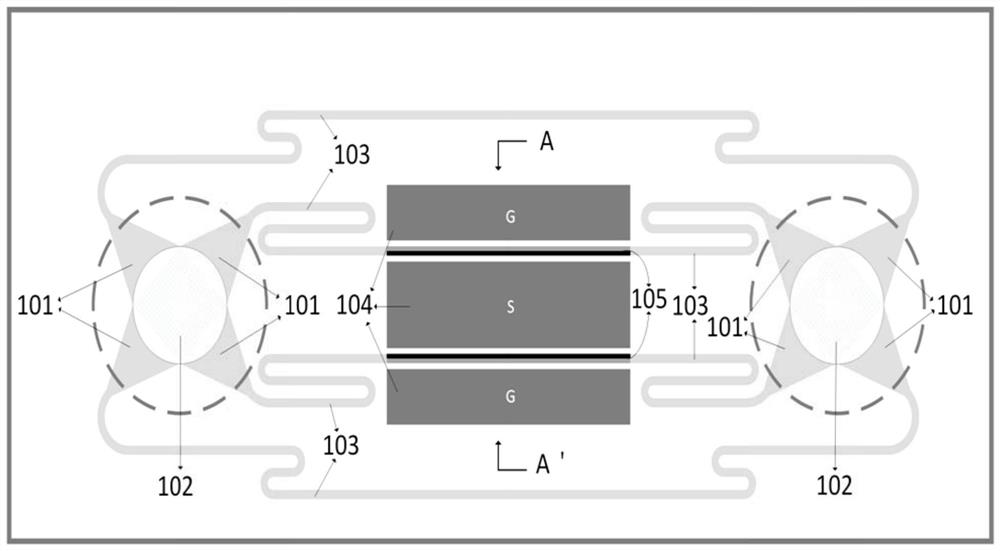

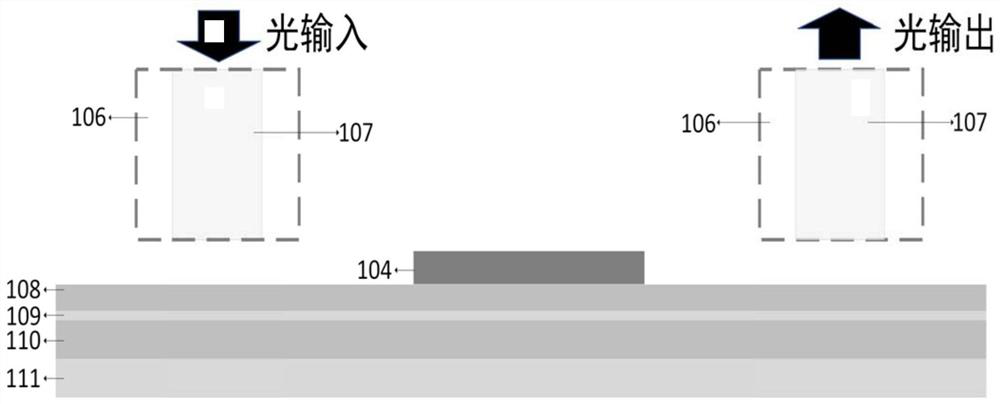

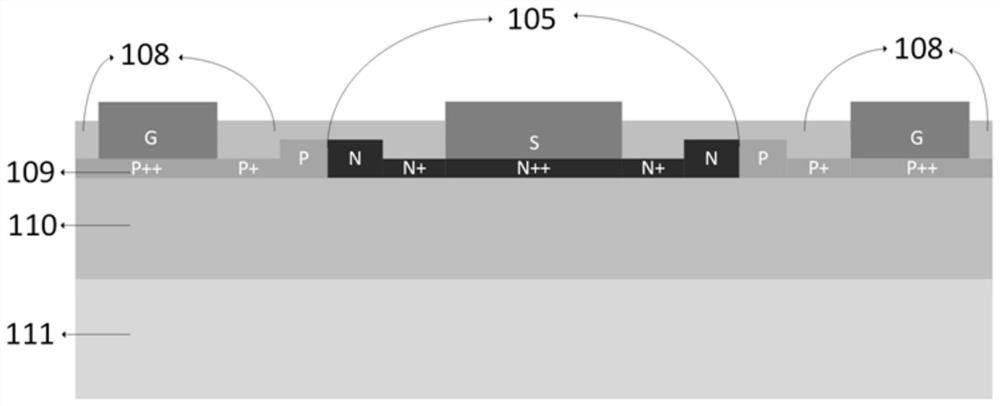

[0031] This embodiment provides a polarization-independent electro-optic modulator based on two-dimensional grating coupling, such as Figure 1-4 , including substrate 111, lower cladding layer 110, silicon device layer 109, upper cladding layer 108 from bottom to top, and eight mode spot converters 101 and four silicon substrates formed by etching on silicon device layer 109 Optical waveguide 103, two four-channel input\output two-dimensional grating couplers 102, two silicon-based PN junction optical waveguide phase shifters 105, and a GSG single-drive coplanar waveguide traveling wave electrode 104.

[0032] Among t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com