Diffusion process of low-pressure diffusion matching laser SE

A diffusion process and laser technology, applied in the field of solar cells, can solve the problems of poor diffusion process quality, aggravating the gap between silicon wafer doping concentration and edge, reducing photoelectric conversion efficiency and electrical performance yield and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

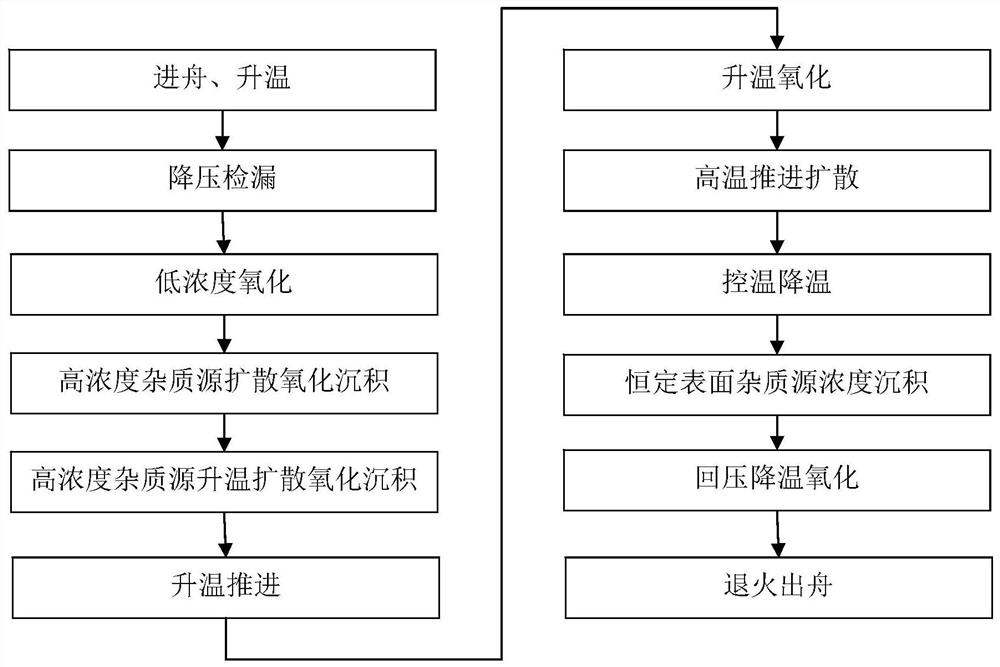

[0050] A low-voltage diffusion matching laser SE diffusion process, the diffusion process of the three groups of embodiment numbers of numbers SY001-003, such as figure 1 shown, including the following steps:

[0051] (1) Entering the boat and heating up: Insert the cleaned silicon wafer into the quartz boat and send it into the furnace tube of the diffusion equipment. During this process, nitrogen protection is introduced to preheat and heat up. The temperature is controlled to rise to 760 ° C ~ 800 ° C °C, the corresponding diffusion parameters of each example number refer to the following table 1-1.

[0052] Table 1-1 Process parameters corresponding to different numbers of diffusion processes

[0053]

[0054] (2) Step-down leak detection: start the vacuum pump, pump the pressure from normal pressure to low-pressure vacuum, and perform a leak detection test, wherein the pressure control is less than or equal to 100mbar, and the leak rate requirement is <2mbar / min; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com