Application of tripolyphosphate mixed transition metal sodium salt in preparation of lithium ion battery or zinc ion battery

A lithium-ion battery, zinc-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unsuitable high-current charge and discharge, low ionic conductivity, poor electronic and ionic conductivity, etc. Working voltage, high performance working voltage, effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] CH 3 COONa, Mn(CH 3 COO) 2 and NH 4 h 2 PO 4 Weigh according to the stoichiometric ratio (molar ratio) of Na:Mn:P=3:2:3, and add citric acid monohydrate as a chelating agent with twice the amount of Mn element, add deionized water to dissolve, 80°C Constant temperature magnetic stirring and drying to obtain wet gel;

[0056] Then dry in an oven at 150°C for 12 hours to obtain dry gel; grind to obtain powder;

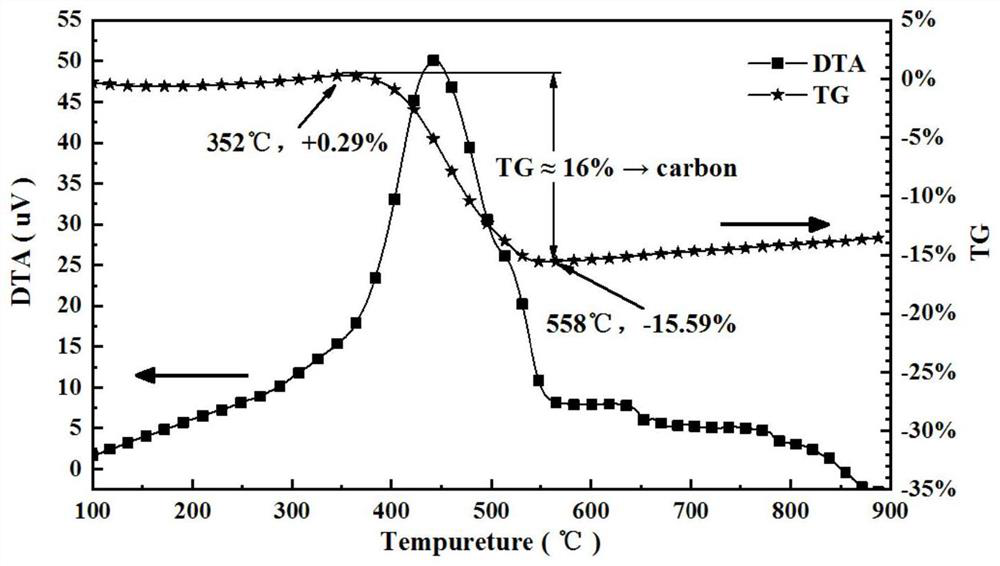

[0057] Then pre-fire the above product at 350°C for 5h in a 5% hydrogen-argon mixed gas, and then grind it after natural cooling. After grinding evenly, a powder material is obtained; after grinding again evenly, burn it in a 5% hydrogen-argon mixed atmosphere at 600°C for 8h , to obtain carbon-coated tripolyphosphate mixed transition metal sodium salt (manganese) (Na 3 mn 2 P 3 o 11 ).

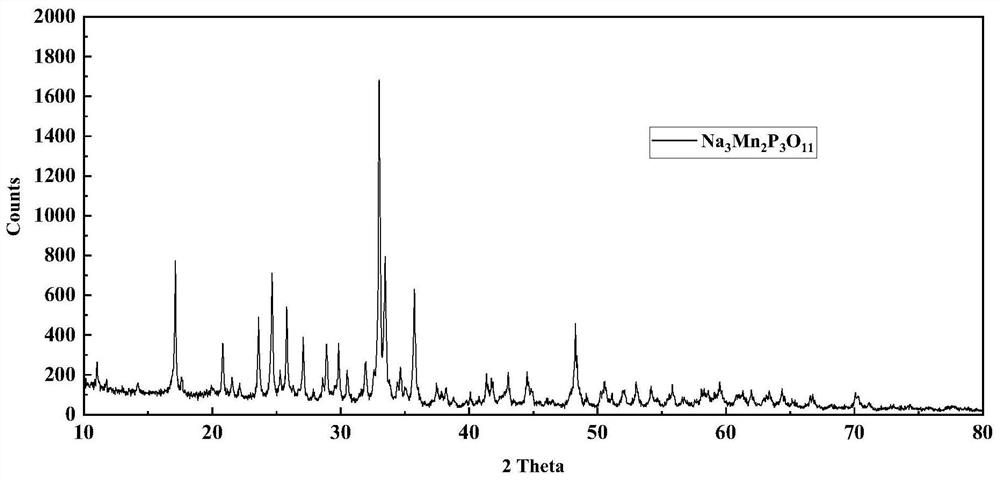

[0058] The XRD spectrum of the product obtained in this example was collected on a Bruker D8 ADVANCE powder crystal diffractometer, with Cu-Kα (λ=0.154nm) as the light...

Embodiment 2

[0065] CH 3 COONa, CH 3 COOK, Mn(CH 3 COO) 2 and NH 4 h 2 PO 4 Weigh it according to the stoichiometric ratio (molar ratio) of Na:K:Mn:P=2.8:0.2:2:3, and add citric acid monohydrate of twice the amount of Mn element as a chelating agent, add deionized water to dissolve , 80 ℃ constant temperature magnetic stirring drying to obtain wet gel;

[0066] Then dry in an oven at 150°C for 12 hours to obtain dry gel; grind to obtain powder;

[0067] Then pre-fire the above product at 350°C for 5h in a 5% hydrogen-argon mixed gas, and then grind it after natural cooling. After grinding evenly, a powder material is obtained; after grinding again evenly, burn it in a 5% hydrogen-argon mixed atmosphere at 600°C for 8h , to obtain carbon-coated tripolyphosphate mixed transition metal sodium salt (potassium manganese) (Na 2.8 K 0.2 mn 2 P 3 o 11 ).

[0068] The XRD spectrum of the product obtained in this example was collected on a Bruker D8 ADVANCE powder crystal diffractometer...

Embodiment 3

[0072] CH 3 COONa, FeSO 4 , Mn(CH 3 COO) 2 and NH 4 h 2 PO 4 Take by weighing the stoichiometric ratio (mol ratio) of Na:Fe:Mn:P=3:0.4:1.6:3, and add twice the monohydrate citric acid of the molar sum of Mn and Fe element as chelating agent, Add deionized water to dissolve, and dry at 80°C with constant magnetic stirring to obtain a wet gel;

[0073] Then dry in an oven at 150°C for 12 hours to obtain dry gel; grind to obtain powder;

[0074] Then pre-fire the above product at 350°C for 5h in a 5% hydrogen-argon mixed gas, and then grind it after natural cooling. After grinding evenly, a powder material is obtained; after grinding again evenly, burn it in a 5% hydrogen-argon mixed atmosphere at 600°C for 8h , to obtain carbon-coated tripolyphosphate mixed transition metal sodium salt (ferromanganese) (Na 3 mn 1.6 Fe 0.4 P 3 o 11 ).

[0075] The XRD spectrum of the product obtained in this example was collected on a Bruker D8 ADVANCE powder crystal diffractometer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com