Preparation method of concentrated pig ossein and application thereof

A technology of pig bone and pig bone, which is applied in the direction of food science, etc., can solve the problems of complex preparation process and waste of resources, and achieve the effects of high decomposition rate, reduced oxidation, and milky white color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a kind of preparation method of concentrated porcine bone extract, comprises the following steps:

[0019] The pig bone raw material is subjected to subcritical water hydrolysis, and the hydrolyzed solution is filtered and concentrated to obtain concentrated porcine bone; the subcritical water hydrolysis is carried out in an oxygen-free environment.

[0020] In the present invention, the pig bone raw material is preferably pig leg bone, skull or scapula; the pig bone raw material is preferably crushed into bone dregs before subcritical water treatment; the diameter of the bony dregs is preferably 1-3 cm. In the present invention, the pork bone raw material is preferably soaked and washed before crushing, and the accompanying meat is removed to remove excess blood stains and floating foam, thereby reducing the protein and fat contained in the meat, and ensuring that the color of the bone broth is pure and without burnt Muddy. In the present invent...

Embodiment 1

[0027] (1) Pretreatment and crushing

[0028] Wash 250g of fresh pork leg bones, remove any attached meat as much as possible, then use a bone crusher to crush the pork leg bones into bone residues with a diameter of 1 cm, rinse and soak them in clean water until there are no blood stains and foam in the bone residues .

[0029] (2) Subcritical water treatment

[0030] Put the pig leg bone slag into a subcritical device reaction tank, add 500g of pure water and mix well, replace the air in the reaction tank with nitrogen, keep the pressure at 0.5Mpa, and the reaction temperature at 110°C for 1 hour , to obtain pork leg bone hydrolyzate.

[0031] (3) filter

[0032] The obtained pig leg bone hydrolyzate is filtered with a plate and frame ultrafiltration machine with a filter membrane pore size of 0.4 μm to remove unhydrolyzed pig bone residues to obtain pig bone broth.

[0033] (4) concentrated

[0034] Use a rotary evaporator to concentrate the original pork bone broth at...

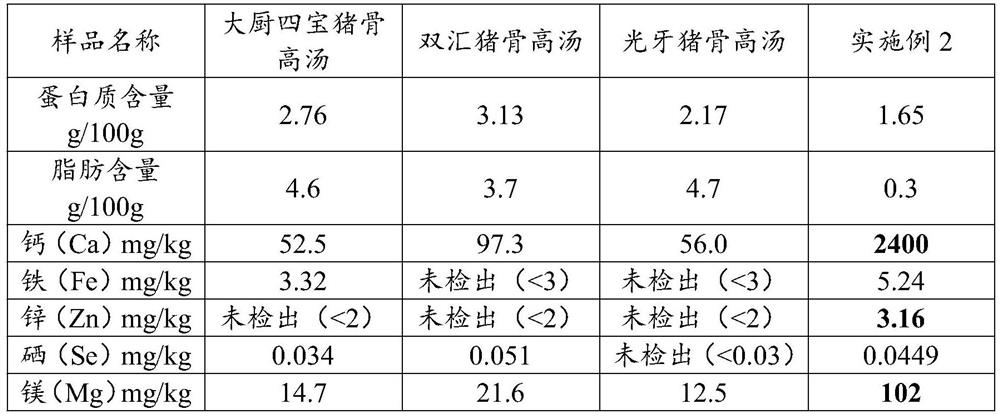

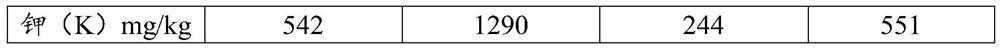

Embodiment 2

[0036] (1) Pretreatment and crushing

[0037] Wash 250g of fresh pork leg bones, remove any attached meat as much as possible, then use a bone crusher to crush the pork leg bones into bone residues with a diameter of 3 cm, rinse and soak them in clean water until there are no blood stains and foam in the bone residues .

[0038] (2) Subcritical water treatment

[0039] Put the pig leg bone slag into a subcritical device reaction tank, add 750g of pure water and mix well, replace the air in the reaction tank with nitrogen, keep the pressure at 1Mpa, and the reaction temperature at 120°C for 1 hour. Obtain pork leg bone hydrolyzate.

[0040] (3) filter

[0041] The obtained pig leg bone hydrolyzate is filtered with a plate and frame ultrafiltration machine with a filter membrane pore size of 0.5 μm to remove unhydrolyzed pig bone residues to obtain pig bone broth.

[0042] (4) concentrated

[0043] Use a rotary evaporator to concentrate the original pork bone broth at a tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com