Continuous preparation method of chloroformate

A technology of chloroformate and hydrogen chloride, which is applied in the preparation of phosgene or haloformate, organic chemistry, etc., can solve the problems of low single-pot production efficiency, high cost of waste gas treatment, high investment in fixed assets, and improve equipment utilization Efficiency, reducing the process of solvent removal and solvent recovery, and reducing the effect of auxiliary production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

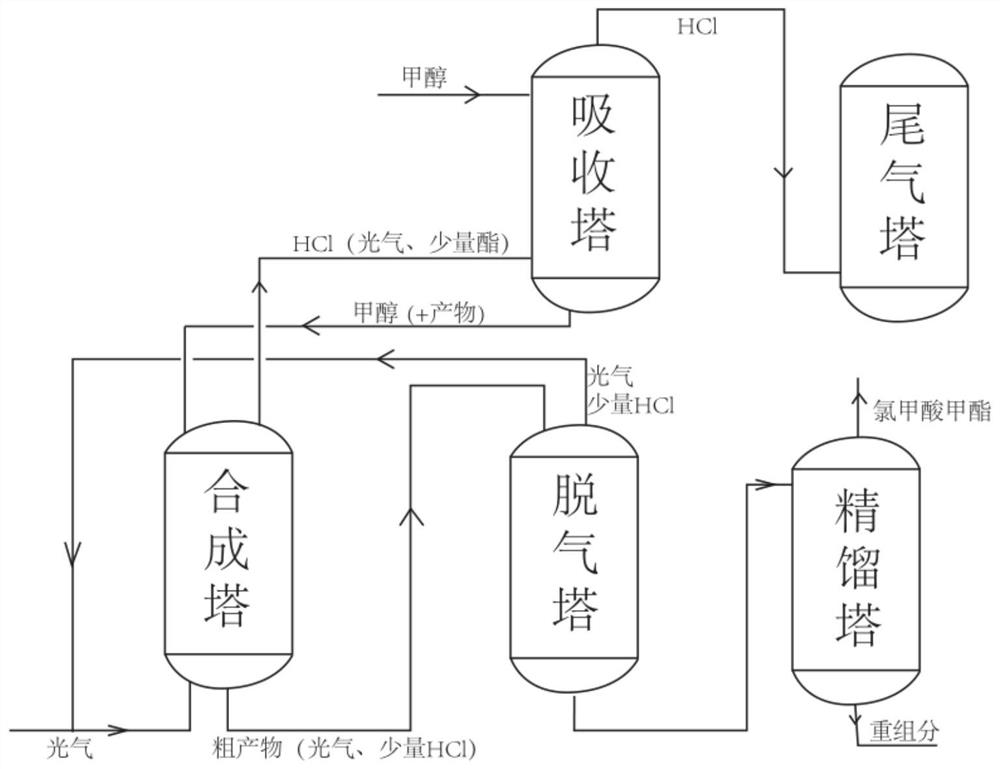

[0043] The process flow chart of the present invention's preparation methyl chloroformate is as figure 1 As shown, it specifically includes the following steps:

[0044] 1) The reactants methanol and phosgene are placed in the synthesis tower at a molar ratio of 1:1.1 for reaction, wherein methanol enters through the absorption tower at the top of the synthesis tower, and phosgene enters from the bottom of the synthesis tower, and the reaction temperature is 25 ℃, the two form a countercurrent in the synthesis tower and fully contact with each other to form the crude product methyl chloroformate and by-product hydrogen chloride;

[0045] 2) The crude product methyl chloroformate formed in the synthetic tower flows out from the bottom of the tower into the degassing tower. Carry out the removal of phosgene, and the released phosgene is combined with the raw material phosgene into the synthesis tower through pipelines to complete the recovery of phosgene; a small amount of hydr...

Embodiment 2

[0049]The method for preparing ethyl chloroformate of the present invention specifically comprises the following steps:

[0050] 1) The reactants ethanol and phosgene are placed in the synthesis tower at a molar ratio of 1:1.15 for reaction, wherein ethanol enters through the absorption tower at the top of the synthesis tower, phosgene enters from the bottom of the synthesis tower, and the reaction temperature is: At 20°C, the two form a countercurrent in the synthesis tower and fully contact with each other to form the crude product ethyl chloroformate and the by-product hydrogen chloride;

[0051] 2) The crude product ethyl chloroformate formed in the synthesis tower flows out from the bottom of the tower into the degassing tower. The top of the degassing tower is 40°C / the temperature of the bottom of the tower is 60°C, and the pressure at the top of the tower is -0.08MPa. Carry out the removal of phosgene, and the released phosgene is combined with the raw material phosgene...

Embodiment 3

[0053] The method for preparing benzyl chloroformate of the present invention specifically comprises the following steps:

[0054] 1) Put the reactants benzyl alcohol and phosgene in the synthesis tower at a molar ratio of 1:1.05, where the benzyl alcohol enters the top of the synthesis tower through the absorption tower, and the phosgene enters from the bottom of the synthesis tower. The temperature is: 15°C, the two form a countercurrent in the synthesis tower and fully contact with each other to form the crude product benzyl chloroformate and the by-product hydrogen chloride;

[0055] 2) The crude product benzyl chloroformate formed in the synthesis tower flows out from the bottom of the tower into the degassing tower. The removal of phosgene is carried out in the degassing tower, and the released phosgene is combined with the raw material phosgene into the synthesis tower to complete the recovery of phosgene; a small amount of hydrogen chloride gas in the degassing tower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com