Chitosan-gallic acid graft copolymer as well as preparation method and application thereof

A technology of graft copolymer and gallic acid, which is applied in the field of chitosan-gallic acid graft copolymer, can solve the problems of complex operation, unsatisfactory grafting rate, and environmental pollution, and achieve high grafting rate and excellent antibacterial , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

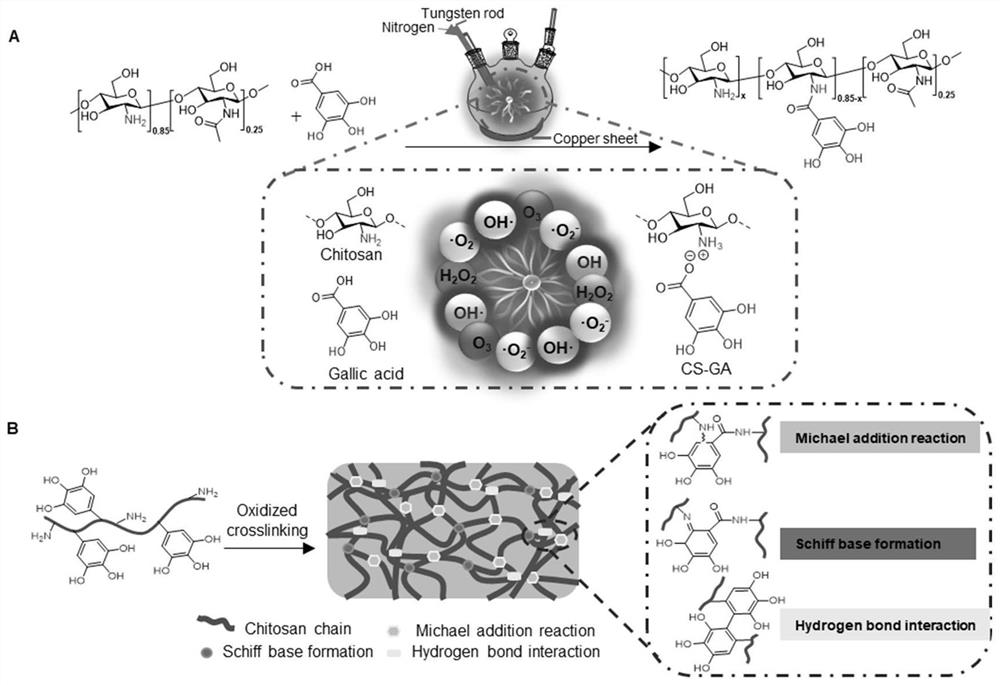

[0039] A preparation method of chitosan (CS) surface grafted gallic acid (GA):

[0040](1) Weigh 1g of chitosan and 1.05g of gallic acid (PAR=1.0) in a 250mL three-necked bottle, stir and dissolve with 100mL of 1% hydrochloric acid / water solution (v / v), adjust with 0.1mol / L sodium hydroxide solution The pH is 3. Nitrogen (3L / min), with copper as the cathode, fix the copper at the bottom of the there-necked bottle, use the tungsten rod as the anode, soak the tungsten rod to the position 1cm below the liquid surface, after the power is turned on, the discharge voltage is 9kV , 0.5A discharge current for 20min discharge (without stirring). After the discharge was completed, the reaction bottle was transferred to a constant temperature oil bath at 85° C. to continue the polymerization reaction for 3 h.

[0041] (2) Ultrapure water dialysis (MWCO: 14000 Da) for 48 hours to remove gallic acid not grafted onto chitosan, and freeze-drying to obtain gallic acid / chitosan graft copolym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com