Antibacterial viscose fiber added with rare earth oxide and preparation method of antibacterial viscose fiber

A rare earth oxide and viscose fiber technology, applied in the direction of man-made filaments made of viscose, can solve the problems of mismatch, rare earth elements do not have antibacterial effect, etc., and achieve difficult agglomeration, good spinnability, and good dispersion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of the antibacterial viscose fiber that adds rare earth oxide, comprises the following steps:

[0025] Firstly, the rare earth nano-antibacterial suspension is prepared: the rare earth antibacterial powder with good antibacterial effect is processed by a sand mill with temperature control, and the rare earth antibacterial suspension is prepared.

[0026] (1) Take by weight 20 parts of rare earth antibacterial powder (cerium oxide: mass ratio of rare earth oxide=95:5), dispersant (polycarboxylate ammonium salt dispersant: the quality of nonionic polymer dispersant Ratio = 1:1) 6 parts, 50 parts of water, 1 part of 1mol / L sodium hydroxide solution, first add all the water and 2 parts of dispersant to the circulation tank of the sand mill, and wait until the dispersant is fully mixed in water .

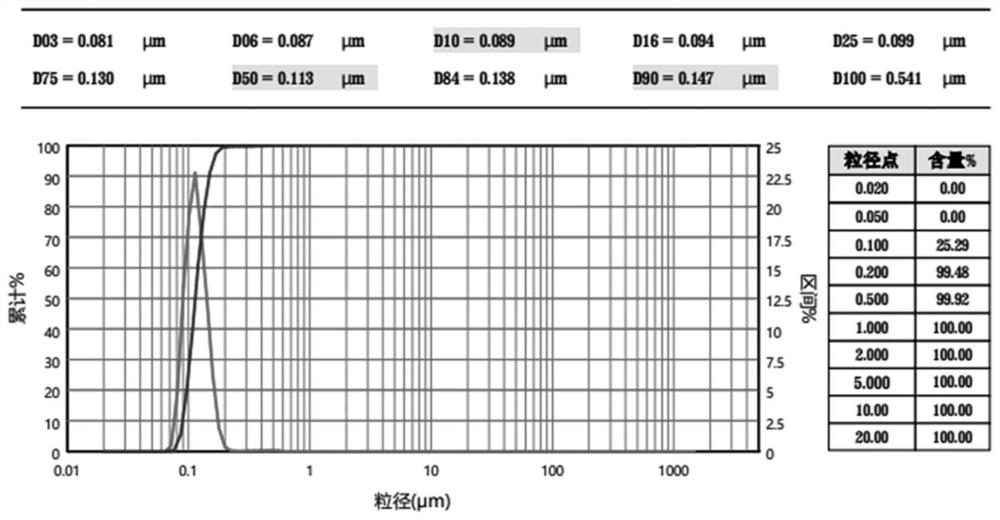

[0027] (2) Use 0.1mm zirconia balls for sand milling, the cavity temperature of the sand mill is controlled at 20°C-22°C, and the speed of the sand m...

Embodiment 2

[0031] A kind of preparation method of the antibacterial viscose fiber that adds rare earth oxide, comprises the following steps:

[0032] Firstly, the rare earth nano-antibacterial suspension is prepared: the rare earth antibacterial powder with good antibacterial effect is processed by a sand mill with temperature control, and the rare earth antibacterial suspension is prepared.

[0033] (1) Weigh 25 parts of rare earth antibacterial powder (cerium oxide: rare earth oxide: copper oxide mass ratio=93:5:2), dispersant (water-based acrylic polymer: containing rare earth affinity group) by weight The mass ratio of polymer block copolymer=4:1) 8 parts, 55 parts of water, 2 parts of 1mol / L sodium hydroxide solution, first add all the water and 2 parts of dispersant to the circulation cylinder of the sand mill, Thoroughly mix the dispersant in water.

[0034] (2) Use 0.1mm zirconia balls for sand milling, the chamber temperature of the sand mill is controlled at 22°C-24°C, and the...

Embodiment 3

[0037] A kind of preparation method of the antibacterial viscose fiber that adds rare earth oxide, comprises the following steps:

[0038] Firstly, the rare earth nano-antibacterial suspension is prepared: the rare earth antibacterial powder with good antibacterial effect is processed by a sand mill with temperature control, and the rare earth antibacterial suspension is prepared.

[0039](1) Take by weight 30 parts of rare earth antibacterial powder (cerium oxide), 12 parts of dispersant (maleic acid styrene-based dispersant: mass ratio=1:1 of ultra-macromolecular polymer dispersant containing carboxyl group), 55 parts of water, 3 parts of 1mol / L sodium hydroxide solution, first add all the water and 3 parts of dispersant to the circulation cylinder of the sand mill, and mix the dispersant fully in the water.

[0040] (2) Use 0.1mm zirconia balls for sand milling, the chamber temperature of the sand mill is controlled at 23°C-25°C, and the speed of the sand mill is controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com