Sunscreen emulsion capable of preventing ultraviolet rays and preparation method of sunscreen emulsion

A technology of sunscreen lotion and ultraviolet rays, which is applied in the preparation of amino compounds, carbon-based compounds, chemical instruments and methods, etc., and can solve problems such as allergies, general sunscreen effects, and sunburn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

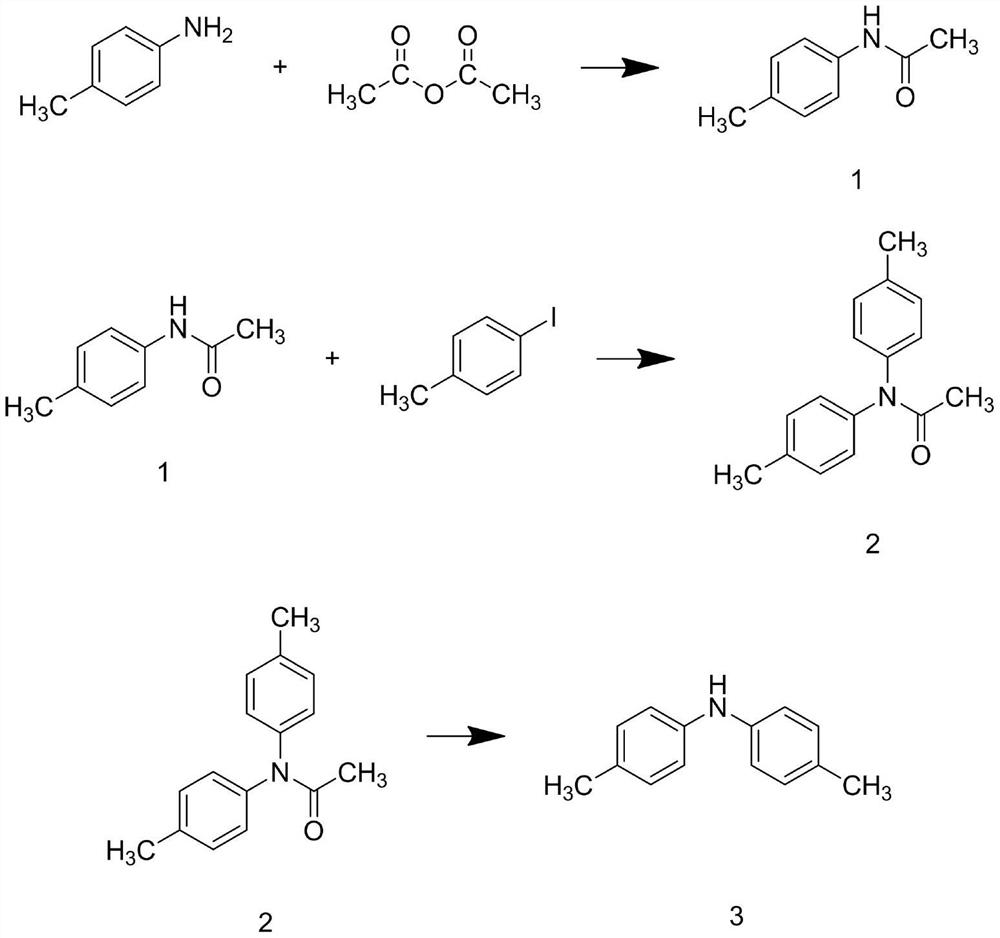

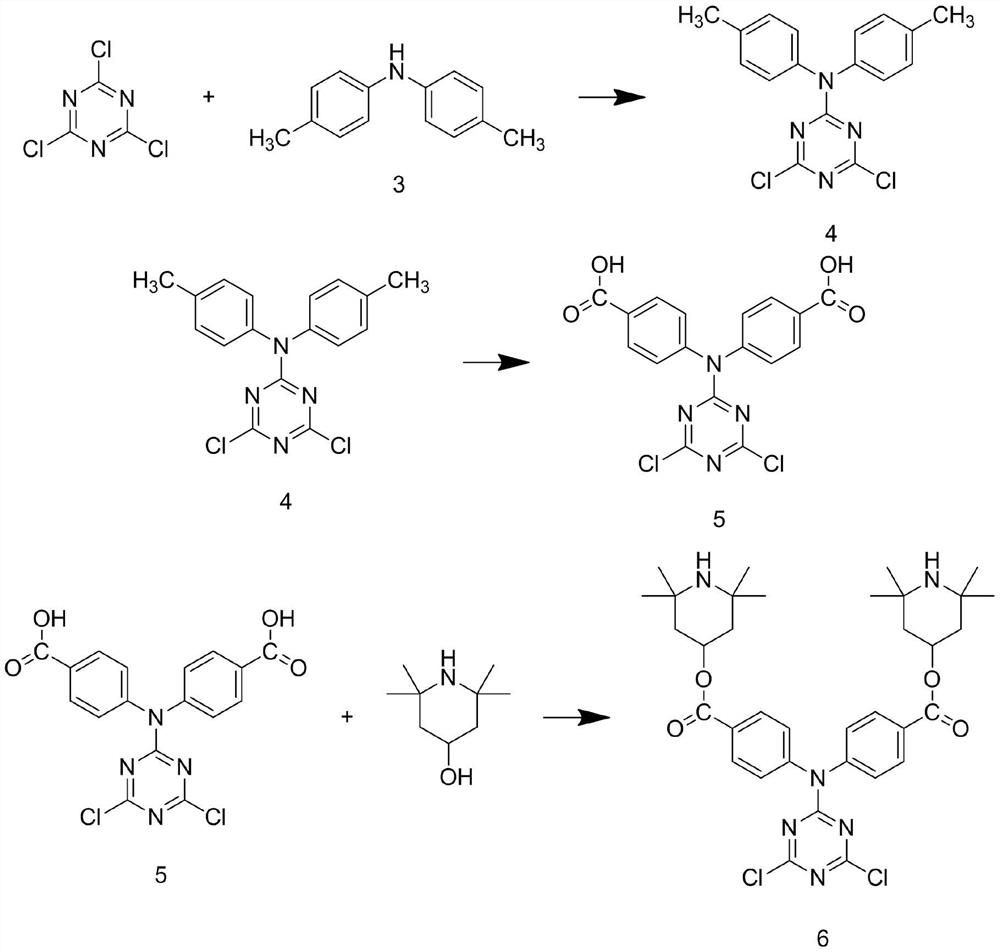

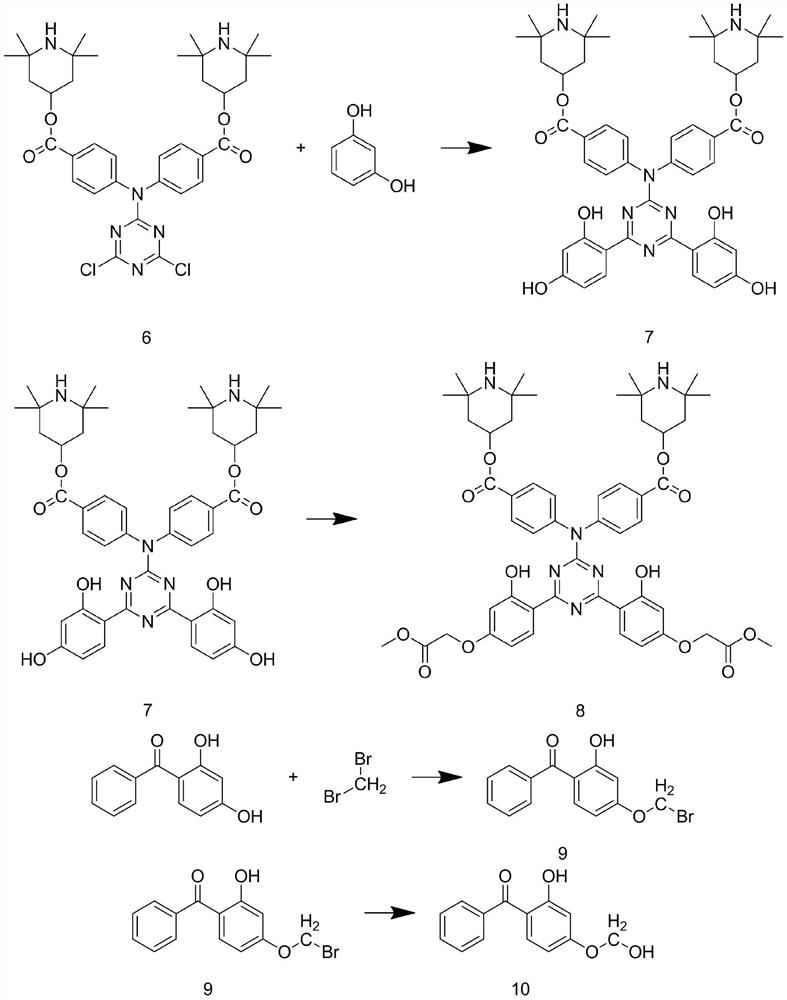

Method used

Image

Examples

Embodiment 1

[0041] A sunscreen lotion for preventing ultraviolet rays, comprising the following raw materials in parts by weight: 3 parts of stearic acid, 2 parts of octyl salicylate, 1 part of sunscreen microcapsules, 0.2 parts of fatty acid methyl ester, 4 parts of glycerin, 15 parts of deionized water, white oil 10 parts, 2 parts of titanium dioxide;

[0042] This sunscreen lotion is made by the following steps:

[0043] Step S1: Add stearic acid, octyl salicylate, sunscreen microcapsules, and fatty acid methyl ester into the stirring tank, and mix evenly to prepare the first mixture;

[0044] Step S2: After mixing the glycerin and deionized water, keep the temperature at 80° C. for 10 minutes to prepare the second mixture;

[0045] Step S3: adding white oil and titanium dioxide into the stirring tank, and mixing evenly to obtain the third mixture;

[0046] Step S4: After the first mixture and the third mixture are uniformly mixed, the second mixture is added, and the mixture is cont...

Embodiment 2

[0054] A sunscreen lotion for preventing ultraviolet rays, comprising the following raw materials in parts by weight: 4 parts of stearic acid, 2.5 parts of octyl salicylate, 1.3 parts of sunscreen microcapsules, 0.3 parts of fatty acid methyl ester, 5 parts of glycerin, 18 parts of deionized water, white oil 13 parts, 2.5 parts of titanium dioxide;

[0055] This sunscreen lotion is made by the following steps:

[0056] Step S1: Add stearic acid, octyl salicylate, sunscreen microcapsules, and fatty acid methyl ester into the stirring tank, and mix evenly to prepare the first mixture;

[0057] Step S2: After mixing the glycerin and deionized water, keep the temperature at 80° C. for 15 minutes to prepare the second mixture;

[0058] Step S3: adding white oil and titanium dioxide into the stirring tank, and mixing evenly to obtain the third mixture;

[0059] Step S4: After the first mixture and the third mixture are uniformly mixed, the second mixture is added, and the mixture ...

Embodiment 3

[0067] A sunscreen lotion for preventing ultraviolet rays, comprising the following raw materials in parts by weight: 5 parts of stearic acid, 3 parts of octyl salicylate, 1.5 parts of sunscreen microcapsules, 0.5 parts of fatty acid methyl ester, 6 parts of glycerin, 20 parts of deionized water, white oil 15 parts, 3 parts of titanium dioxide;

[0068] This sunscreen lotion is made by the following steps:

[0069] Step S1: Add stearic acid, octyl salicylate, sunscreen microcapsules, and fatty acid methyl ester into the stirring tank, and mix evenly to prepare the first mixture;

[0070] Step S2: After mixing the glycerin and deionized water, keep the temperature at 90° C. for 15 minutes to prepare the second mixture;

[0071] Step S3: adding white oil and titanium dioxide into the stirring tank, and mixing evenly to obtain the third mixture;

[0072] Step S4: After the first mixture and the third mixture are uniformly mixed, the second mixture is added, and the mixture is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com