Vehicle connecting rod blank machining process

An automobile connecting rod and blank processing technology, which is applied in the field of auto parts, can solve the problems of high energy consumption, complicated process, and unsatisfactory performance of connecting rod blanks, and achieves the effects of good dispersion, more toughness and less voids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

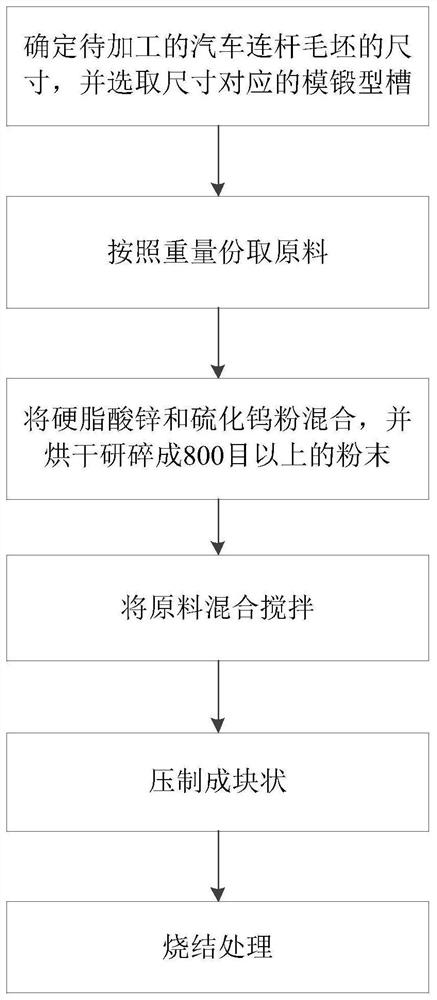

Method used

Image

Examples

Embodiment 1

[0030] 1) Determine the size of the automobile connecting rod blank to be processed, and select the die forging groove corresponding to the size. The die forging size of the automobile connecting rod blank is: the height of the small head hole is 65mm, the minimum height is 25mm, and the thickness is 8mm , the thickness of the wedge-shaped end face is 7.5mm;

[0031] 2) Take raw materials according to parts by weight: 200 parts of cast steel powder, 15 parts of manganese powder, 10 parts of copper powder, 5 parts of chromium powder, 3 parts of cobalt powder, 3 parts of molybdenum powder, 3 parts of silicon carbide powder, 3 parts of aluminum nitride powder 2 parts, 2 parts of barium titanate powder, 3 parts of zinc stearate, 3 parts of tungsten sulfide powder, wherein, the mass fraction of each component in the cast steel powder is as follows: C: 0.9-1.1%, Mn: 0.8-1.0 %, Si: 0.4-0.6%, the balance is Fe, the cast steel powder, manganese powder, copper powder, chromium powder, c...

Embodiment 2

[0038] 1) Determine the size of the automobile connecting rod blank to be processed, and select the die forging groove corresponding to the size. The die forging size of the automobile connecting rod blank is: the height of the small head hole is 65mm, the minimum height is 25mm, and the thickness is 8mm , the thickness of the wedge-shaped end face is 7.5mm;

[0039] 2) Take raw materials according to parts by weight: 150 parts of cast steel powder, 10 parts of manganese powder, 5 parts of copper powder, 3 parts of chromium powder, 2 parts of cobalt powder, 2 parts of molybdenum powder, 2 parts of silicon carbide powder, 2 parts of aluminum nitride powder 1 part, 1 part of barium titanate powder, 2 parts of zinc stearate, 2 parts of tungsten sulfide powder, wherein, the mass fraction of each component in the cast steel powder is as follows: C: 0.9-1.1%, Mn: 0.8-1.0 %, Si: 0.4-0.6%, the balance is Fe, the cast steel powder, manganese powder, copper powder, chromium powder, coba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com