Core-shell structure titanium-nickel medical implant based on elastic modulus regulation and control, 4D printing forming method and application

An elastic modulus, core-shell structure technology, applied in applications, pharmaceutical formulations, joint implants, etc., can solve the problems of insufficient systematic and in-depth titanium-nickel alloy components, imperfect research on customized structural design and function realization, etc. Satisfy personalized design requirements, improve molding accuracy, and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

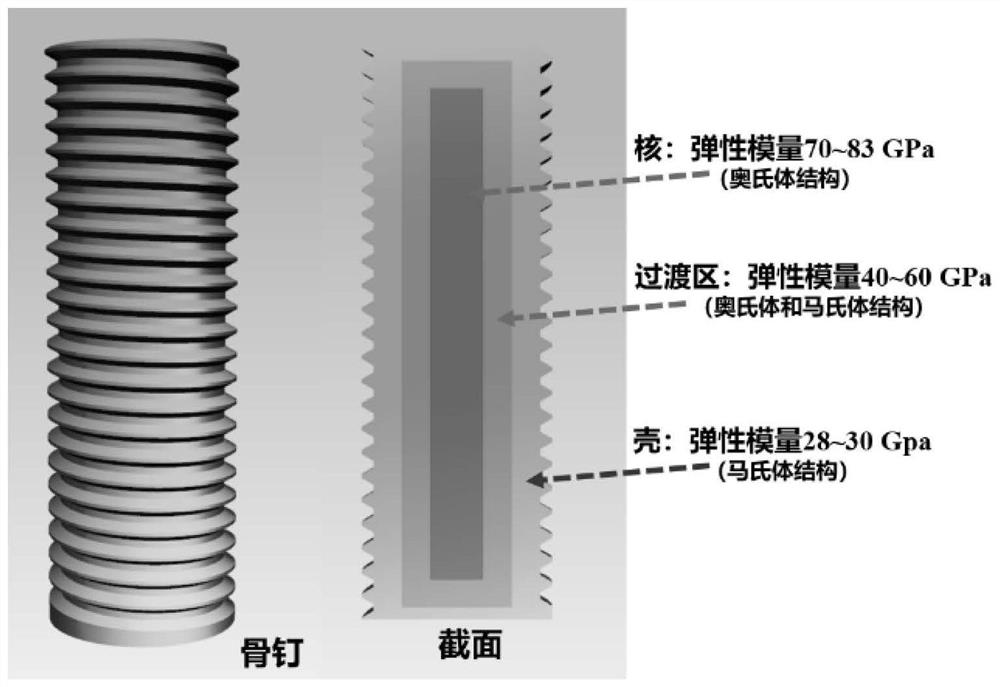

[0039] Embodiment 1 (core-shell structure nickel-titanium alloy bone nail with controllable modulus of elasticity)

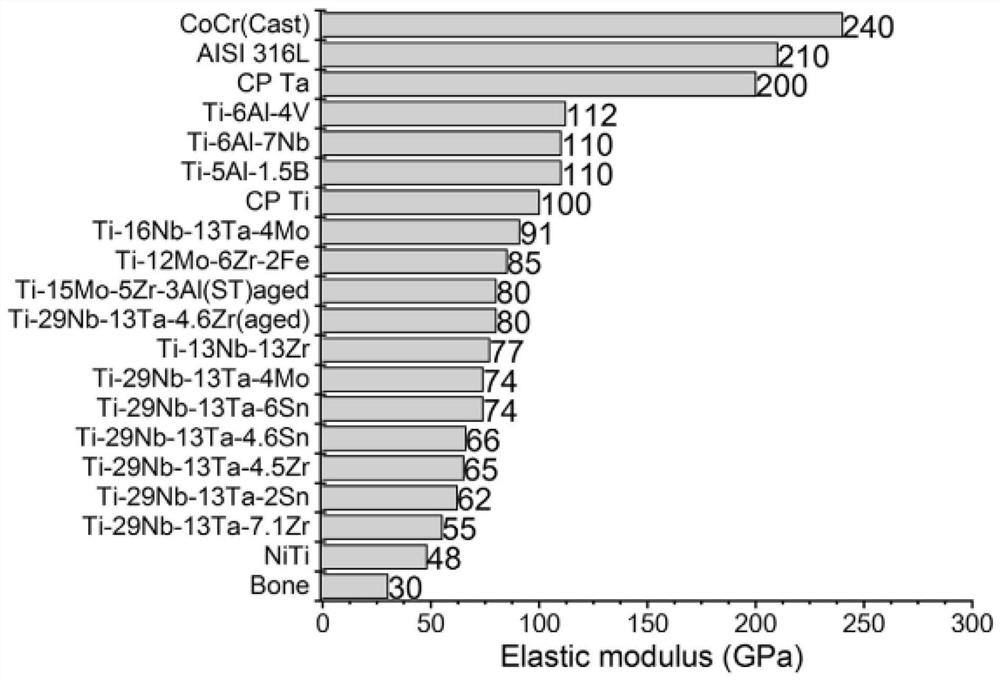

[0040] (1) Design a core-shell structure titanium-nickel alloy bone nail configuration with controllable elastic modulus: According to the force analysis of the implant's service environment and the CT scan results of clinical patients, the outline of the bone nail is obtained and reconstructed by reverse engineering using Geomagic software The model of the bone screw was implanted, the design configuration was optimized, and the stress state of each part of the implant was analyzed by using the finite element simulation software ANSYS. The shell structure is a martensite phase, the core is an austenite structure, and the middle layer except the core shell is a dual-phase structure in which austenite and martensite coexist, so that the bone nail does not produce plastic deformation under cyclic tension and compression. The thickness of the shell structure is 0.5...

Embodiment 2

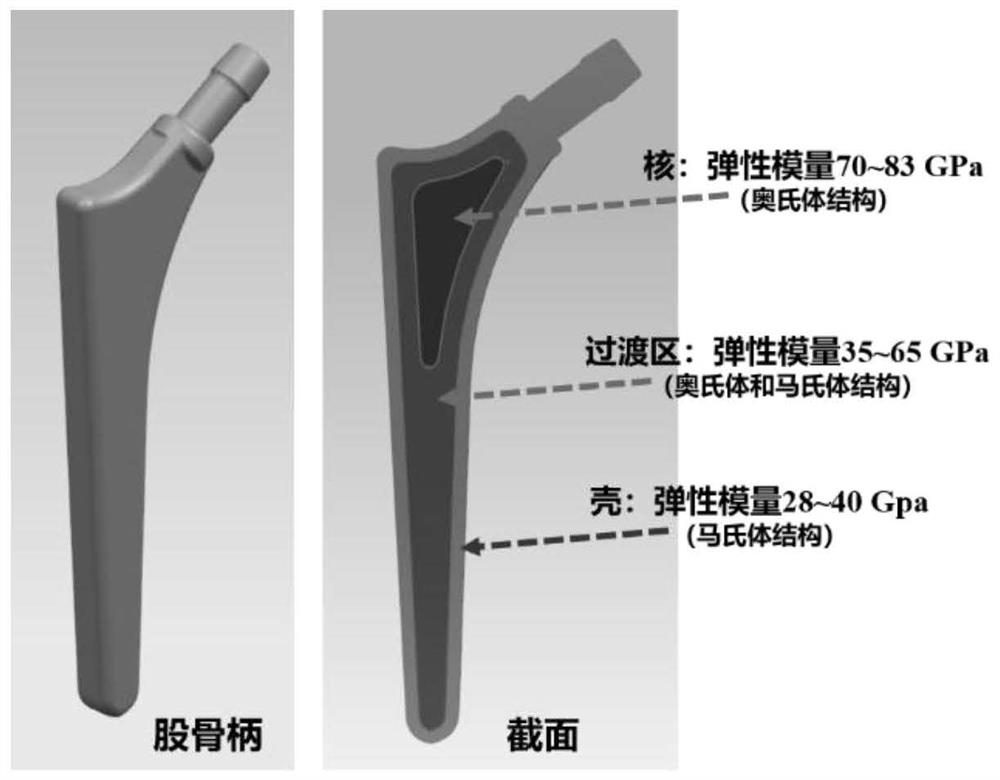

[0044] Embodiment 2 (core-shell structure nickel-titanium alloy femoral stem with controllable modulus of elasticity)

[0045] (1) Design a core-shell titanium-nickel alloy femoral stem configuration with a controllable elastic modulus: According to the force analysis of the implant’s working environment and the CT scan results of clinical patients, the contour of the femoral stem was obtained, and reverse engineering was performed using MIMICS software Rebuild the model of the implanted femoral stem, optimize the design configuration, and use the finite element simulation software ABAQUS to analyze the stress state of each part of the implant. The surface of the femoral stem is in contact with the human bone and bears compressive stress, so the shell part has a low elastic modulus (28-40GPa) martensite phase has a high volume ratio of 50-60%, and a thickness of 0.5-5mm, so that after the end of a single stress, the martensite will not produce plastic deformation when the stres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com