A kind of preparation method of ionic liquid modified graphene composite polyaniline hollow microspheres

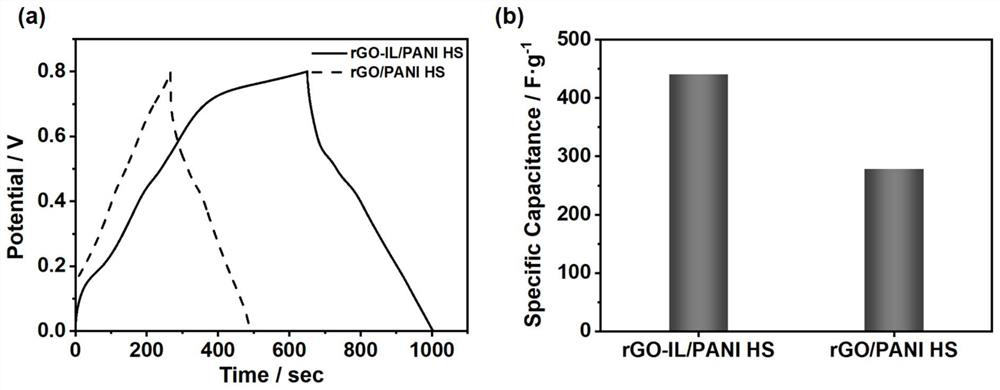

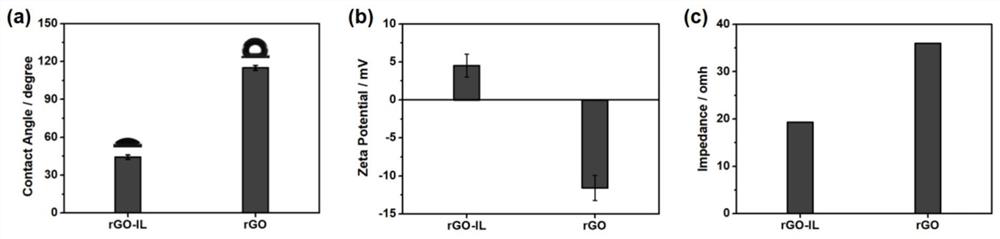

A graphene composite, ionic liquid technology, applied in the field of graphene composite materials, can solve problems such as unsatisfactory electrical conductivity, inability to stabilize Pickering emulsion well, etc., and achieves adjustable droplet size, good ionic conductivity, and design Good effect of uniformity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

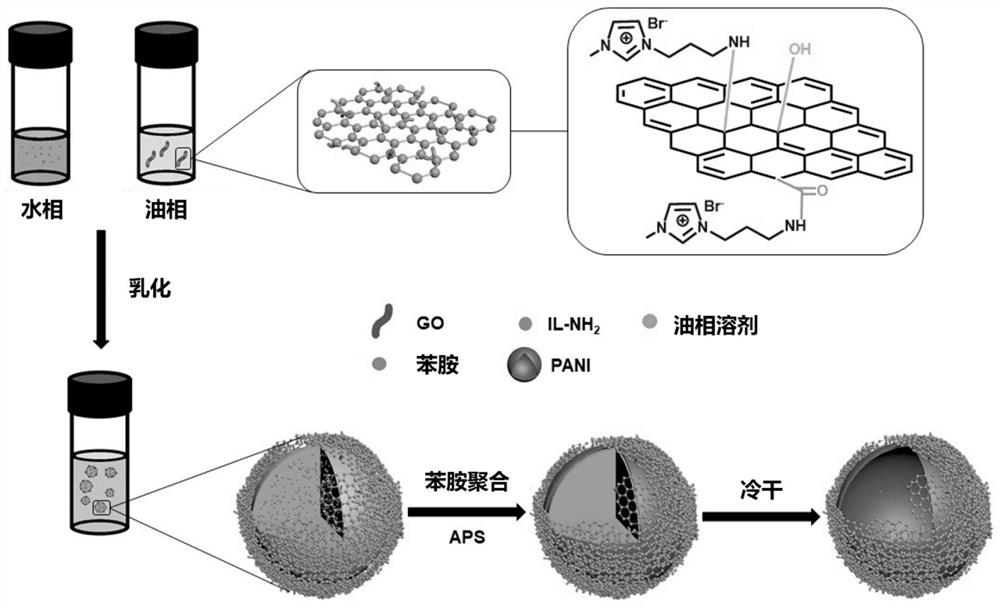

[0031] An ionic liquid modified graphene composite polyaniline hollow microspheres, the preparation method comprising the steps of:

[0032] (1) Preparation of ionic liquid modified reductant oxide oxide

[0033] 90 mg of oxide oxide oxide was dispersed in 300 ml of water to form 0.3 mg / ml of oxide water dispersion, and then 540 mg ionic liquid 1-amine-3-methylimidazole and 225 / 135 / 180 mg catalyst NaOH, The modified reaction was carried out at 85 ° C for 20 h to give the ionic liquid modified grease; after the addition of 90 mg of reducing agent borohydride was added, the reaction was reacted at 95 ° C for 6 h, which was filtered, and the ionic liquid modified reductant oxide, RGO-IL;

[0034] (2) Preparation of water-filled Pickering lotion

[0035] RGO-IL obtained by step (1) was dispersed in water, forming 1 mg / ml of RgO-IL aqueous dispersion, as aqueous phase, as an oil phase containing 2 vol% aniline monomer, and both according to oil ratio 1 : 1 mix, use homogeneous ma...

Embodiment 2

[0039] An ionic liquid modified graphene composite polyaniline hollow microspheres, the preparation method comprising the steps of:

[0040] (1) Preparation of ionic liquid modified reductant oxide oxide

[0041]The 90mg 225mL graphene oxide dispersed in water to form a 0.4mg / graphene oxide mL of an aqueous dispersion, was added 90mg amine ionic liquid 1-ethyl-3-methylimidazolium bromide and 135mg of triethylamine catalyst, at 75 28H ℃ modification reaction carried out, to give the ionic liquid modified graphene oxide; 120mg reducing agent after addition of sodium bisulfite, the reaction 10H, suction filtered, washed with ion-obtained liquid modified reduced graphene oxide at 85 ℃, i.e. rGO-IL;

[0042] (2) Preparation of oil-in-water Pickering emulsion

[0043] The step (1) rGO-IL resulting dispersed in water to form an aqueous dispersion rGO-IL 5mg / mL, the water phase, containing 10vol% ethyl aniline monomer as an oil phase, according to both the oil and water ratio of 1: 5 ...

Embodiment 3

[0047] A method of preparing ionic liquid polyaniline-modified graphene composite hollow microspheres, said process comprising the steps of:

[0048] (1) Preparation of ionic liquid modified reduced graphene oxide

[0049] The 90mg 180mL graphene oxide dispersed in water to form an aqueous dispersion of graphene oxide 0.5mg / mL, and the ionic liquid was added 360mg of 1- (3-aminopropyl) -3-methylimidazolium bromide and 180mg catalyst KOH, carried out at 80 ℃ 24h modification reaction, ionic liquid modified graphene oxide; 180mg after addition of a reducing agent of hydrazine hydrate, the reaction 8h at 90 ℃, by suction filtration, washed with ionic liquid reduced graphene oxide-modified, i.e., rGO-IL;

[0050] (2) Preparation of oil-in-water Pickering emulsion

[0051] The step (1) is prepared rGO-IL dispersed in water to form an aqueous dispersion rGO-IL 3mg / mL, the water phase, containing toluene 8vol% aniline monomer as an oil phase, according to both the ratio of water 1 : ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com