Water-based intumescent fire retardant coating for indoor steel structure and preparation method thereof

A kind of technology of fireproof coating and intumescent type, which is applied in the field of water-based intumescent fireproof coating for indoor steel structures and its preparation, can solve the problem of poor adhesion, difficulty in balancing moisture resistance, water resistance and flame retardancy, and poor moisture resistance and water resistance. Good and other questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

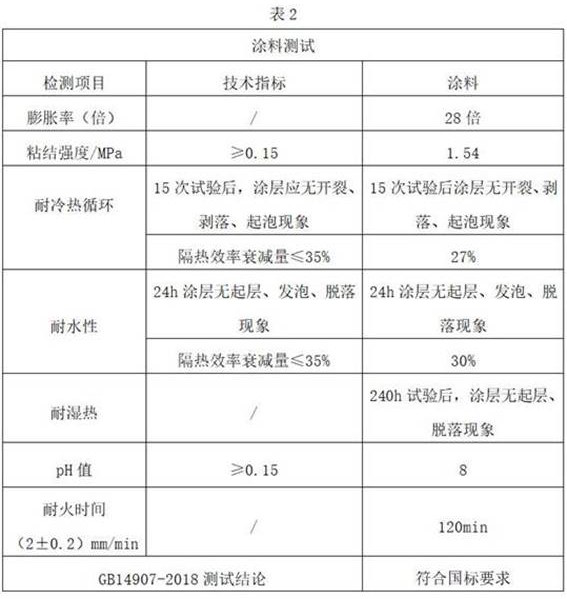

Embodiment 1

[0055]A water-based intumescent fireproof coating for indoor steel structures, comprising the following raw materials in weight percent: 15% film-forming emulsion, 1.2% dispersant, 0.9% thickener, 12% potassium methyl silicate modified pentaerythritol, 11% melamine, 14% ammonium polyphosphate modified by melamine, 12% aluminum hydroxide, 4% glass fiber, 0.6% wetting agent, 0.7% defoamer, 6% pigment (titanium dioxide), and the balance is distilled water.

[0056] Above-mentioned a kind of preparation method that is used for the water-based intumescent type fireproof coating of indoor steel structure, comprises the following steps:

[0057] Step A: add dispersant, wetting agent, and defoamer to distilled water, and stir at 500r / min for 5min;

[0058] Step B: adding glass fiber and stirring at 800r / min for 8min;

[0059] Step C: adding aluminum hydroxide and titanium dioxide and stirring at 1000r / min for 20min;

[0060] Step D: add ammonium polyphosphate, modified pentaerythrit...

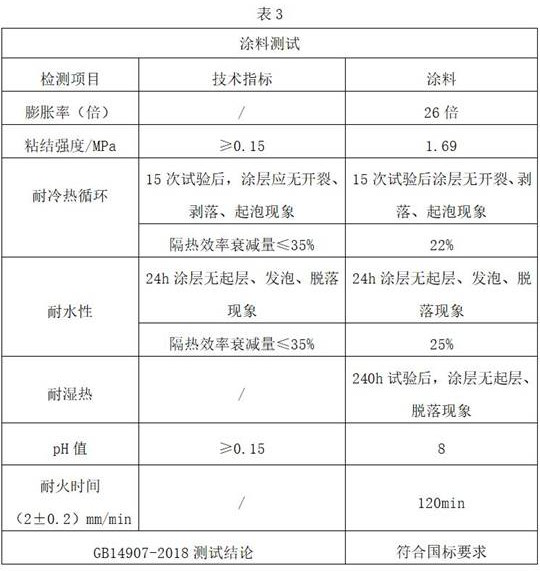

Embodiment 2

[0070] A water-based intumescent fireproof coating for indoor steel structures, comprising the following raw materials in weight percentage: 17% film-forming emulsion, 0.9% dispersant, 1.0% thickener, 10% potassium methyl silicate modified pentaerythritol, 11% melamine, 15% ammonium polyphosphate modified by melamine, 13% aluminum hydroxide, 3% glass fiber, 0.5% wetting agent, 0.6% defoamer, 7% pigment (titanium dioxide), and the balance is distilled water.

[0071] Above-mentioned a kind of preparation method that is used for the water-based intumescent type fireproof coating of indoor steel structure, comprises the following steps:

[0072] Step A: add dispersant, wetting agent and defoamer to distilled water and stir at 800r / min for 8min;

[0073] Step B: adding glass fiber and stirring at 1000r / min for 10min;

[0074] Step C: adding aluminum hydroxide and titanium dioxide and stirring at 1200r / min for 25min;

[0075] Step D: add ammonium polyphosphate, modified pentaeryt...

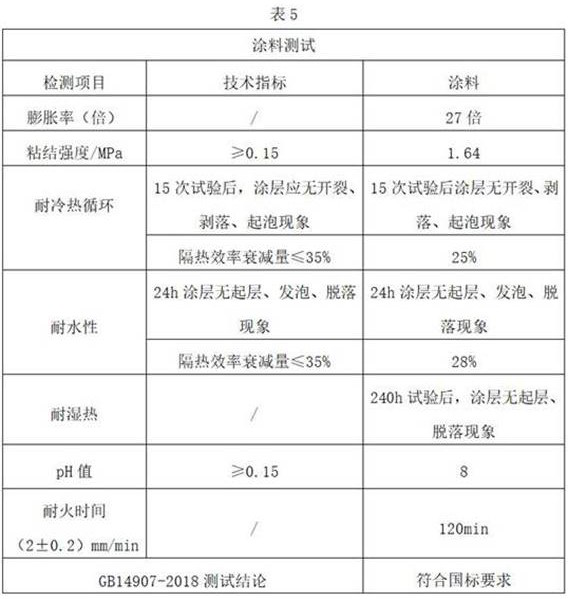

Embodiment 3

[0085] A water-based intumescent fireproof coating for indoor steel structures, comprising the following raw materials in weight percentage: 18% film-forming emulsion, 1.2% dispersant, 0.9% thickener, 9% potassium methyl silicate modified pentaerythritol, 10% melamine, 16% ammonium polyphosphate modified by melamine, 14% aluminum hydroxide, 3% glass fiber, 0.3% wetting agent, 0.8% defoamer, 6% pigment, and the balance is distilled water.

[0086] Above-mentioned a kind of preparation method that is used for the water-based intumescent type fireproof coating of indoor steel structure, comprises the following steps:

[0087] Step A: add dispersant, wetting agent and defoamer to the water and stir at 700r / min for 6min;

[0088] Step B: adding glass fiber and stirring at 900r / min for 9min;

[0089] Step C: adding aluminum hydroxide and titanium dioxide and stirring at 1100r / min for 22min;

[0090] Step D: add ammonium polyphosphate, modified pentaerythritol and melamine and cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com