Titanium carbide reinforced cast iron material and casting manufacturing method thereof

A titanium carbide and cast iron technology, which is applied in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of complex manufacturing methods of connecting arms, difficult space for improvement, low yield and other problems, so as to improve crushing efficiency, reduce costs, improve The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This example focuses on titanium carbide reinforced cast iron materials.

[0046] The applicant found that, on the basis of the existing technology, by improving the powder formation, compounding and / or addition process, and optimizing the composition and proportion of the powder, iron-based composite materials and their products with higher mechanical properties can be obtained.

[0047]Specifically, the applicant found in practice and research that when the number of moles of C is less than the number of moles of Ti, especially if the ratio of the number of moles of C to the number of Ti is kept between 0.7-0.94, C and Ti is all combined to form TiC without residual free C, which can achieve higher strength and toughness; the melting point of carbon powder is higher, while the melting point of iron powder and / or titanium powder is relatively low. When the diameter of carbon powder is smaller than that of iron powder And / or when the diameter of the titanium powder is m...

Embodiment 2

[0069] In this embodiment, the casting is mainly described, and the titanium carbide-reinforced cast iron material in Embodiment 1 is mainly used to prepare it.

[0070] In the prior art, a hollow part is formed through the first connecting arm, the central part and the second connecting arm of the casting. This structure achieves good strength and weight reduction effects, but since the hollow part penetrates through the first connecting The entire length of the central part and the second connecting arm is difficult to accurately locate when arranging the corresponding mold core in the mold, and it is relatively difficult to take it out, which is easy to damage the casting.

Embodiment approach

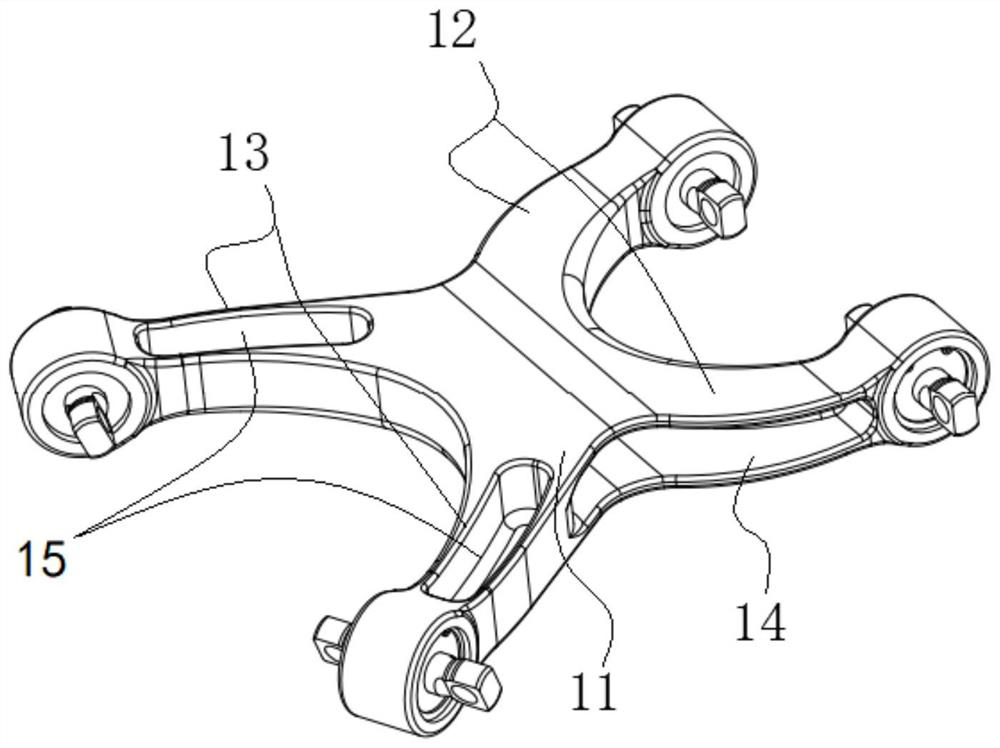

[0071] For this reason, a casting with a new structure is proposed to solve the above problems. According to a preferred embodiment of the present invention, such as figure 1 As shown, the casting includes:

[0072] Central Section 11:

[0073] Two first connecting arms 13 extend to one side from the central part 11 and are arranged symmetrically with respect to a first axis of the central part 11, the first axis extending along the length direction of the casting, the first connecting arms The end of 13 is provided with a first mounting hole; and

[0074] Two second connecting arms 12 extend from the central part 11 to the other side and are arranged symmetrically with respect to the first axis, and the ends of the second connecting arms 12 are provided with second mounting holes;

[0075] Wherein, the upper or lower surface of the first connecting arm 13 is provided with a first weight-reducing groove 15, and the central part 11 is provided with a through hole extending a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com