Preparation device for fluorine-containing polymer fully drawn yarns

A technology of fully drawn yarn and preparation device, which is applied in the directions of drawing spinning, melting of filament raw materials, and complete sets of equipment for producing artificial yarns, can solve the problems of increased environmental burden, poor fluidity, and high melt viscosity, etc. Achieve the effect of strengthening heat setting, improving dimensional stability and reducing heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

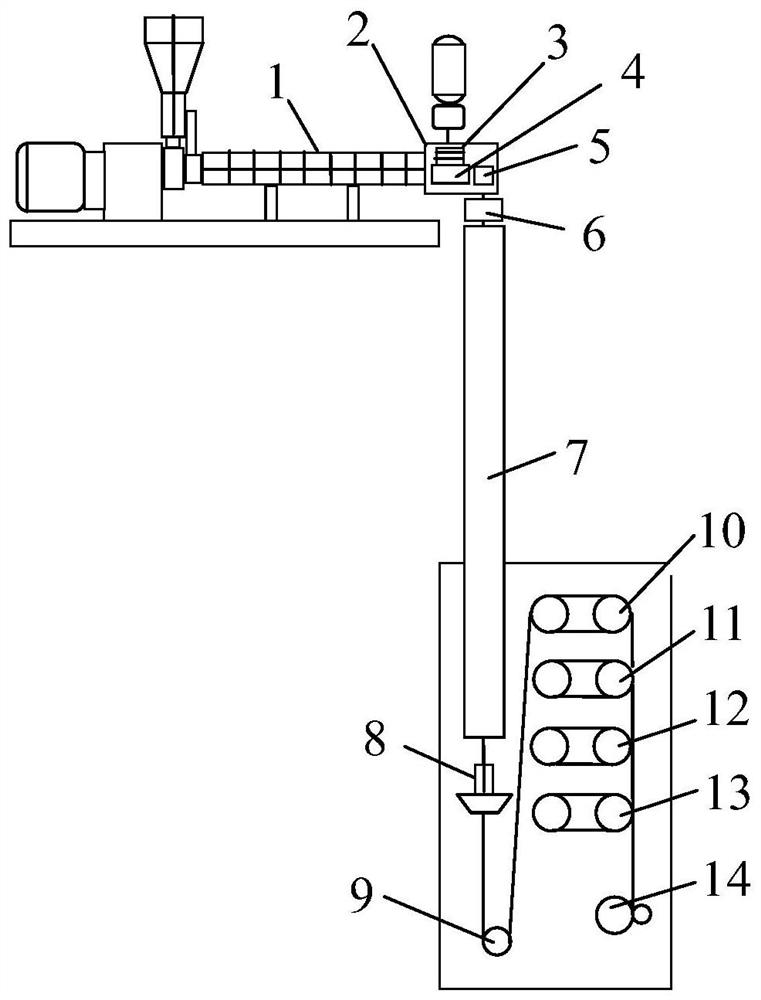

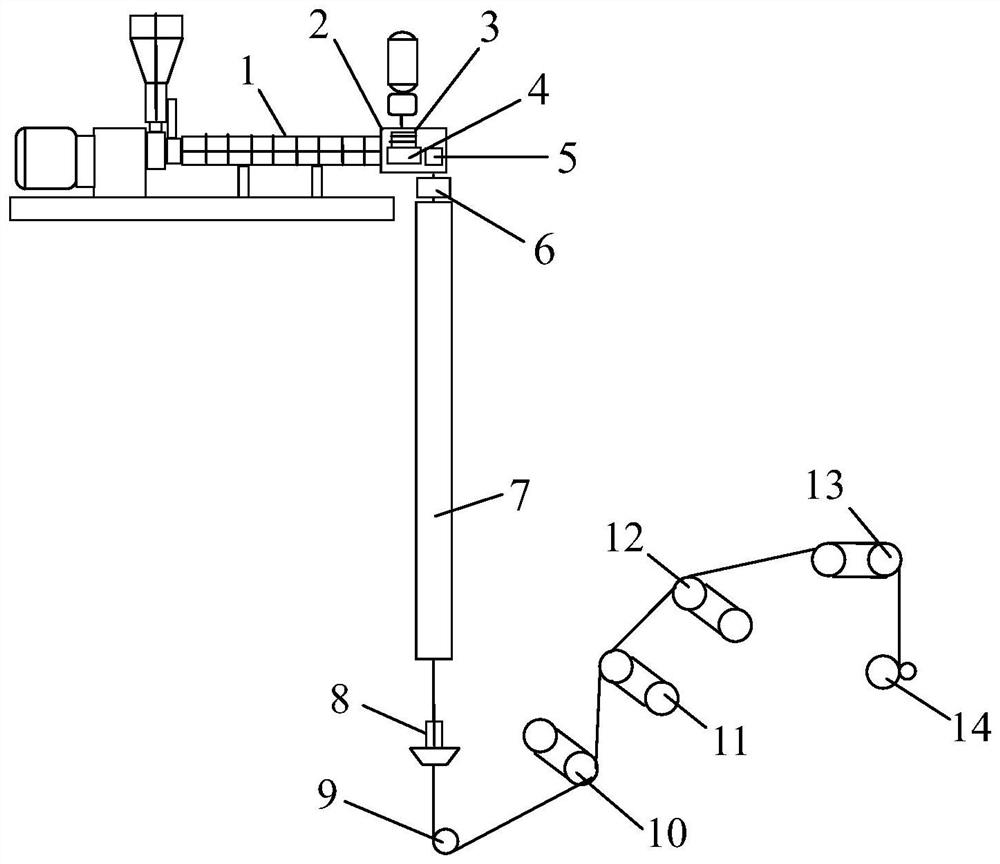

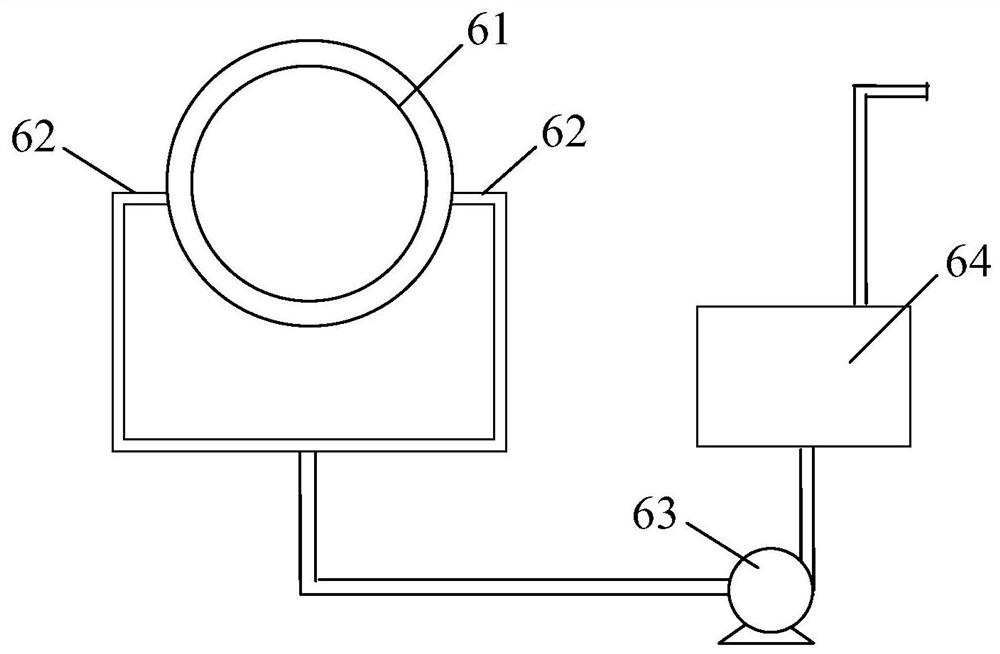

[0033] The polyperfluoroethylene propylene resin chip is used as a raw material, and the polyperfluoroethylene propylene fiber is prepared on the device. Feed the FEP resin chips into the hopper of the screw extruder 1, melt in the screw extruder 1, pass through the pump base 3, the metering pump 4, the pump base 3, and the melt pipeline, and extrude from the spinneret 5 The melt stream is formed; the melt stream passes through the suction device 6, the spinning shaft 7, and the upper oiler 8 vertically downwards, passes through the godet 9 in a tangential direction, and is wound on the first stretching roller 10 to form a primary The fiber is stretched, relaxed, heat-set, and wound to obtain the finished fiber. The corrosive gas produced is treated and discharged through the suction device 6.

[0034] The screw extruder 1 heating zone is divided into three zones, the temperature of the feeding zone is 240-260°C, the temperature of the compression zone is 360-380°C, the tempe...

Embodiment 2

[0037] The polyperfluoroethylene propylene resin chip is used as a raw material, and the polyperfluoroethylene propylene fiber is prepared on the device. The spinning process is the same as in Example 1.

[0038] Among them, the screw heating zone is divided into three zones, the temperature of the feeding zone is 250°C, the temperature of the compression zone is 370°C, and the temperature of the metering zone is 375°C; the temperature of the spinneret 5 is 375°C; the speed of the metering pump 4 is 8r / min; 8. The rotating speed is 10r / min; the temperature of the spinning tunnel 7 is 70°C; the temperature of the first stretching roll 10 is 160°C, and the speed is 100m / min; the temperature of the second stretching roll 11 is 165°C, and the speed is 220m / min; The temperature of the third stretching roll 12 is 180°C and the speed is 210m / min; the temperature of the relaxation heat setting roll 13 is 175°C and the speed is 190m / min; the speed of the winding machine 14 is 185m / min;...

Embodiment 3

[0041] Using polyvinylidene fluoride resin chips as raw materials, polyvinylidene fluoride fibers are prepared on the device. The spinning process is the same as in Example 1.

[0042] The screw heating zone is divided into three zones, the temperature of the feeding zone is 160-180°C, the temperature of the compression zone is 235-255°C, the temperature of the metering zone is 240-260°C; the temperature of the spinneret 5 is 240-260°C; the metering pump 4 The rotating speed is 10-12r / min; the rotating speed of the upper oil tanker 8 is 10-12r / min; the temperature of the spinning shaft 7 is 50-60°C; the temperature of the first drawing roller 10 is 95-110°C, and the speed is 150-170m / min The temperature of the second stretching roll 11 is 110~130°C, and the speed is 410~430m / min; the temperature of the third stretching roll 12 is 115~135°C, and the speed is 420~440m / min; 110-130°C, the speed is 360-380m / min; the speed of the winding machine 14 is 345-365m / min; the speed of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com