Room-temperature all-liquid-state lithium-sulfur battery and preparation method thereof

A liquid lithium and sulfur battery technology, which is applied in the manufacture of lithium batteries, electrolyte batteries, secondary batteries, etc., can solve the problems of inconvenient use of solid-state lithium-sulfur batteries, and achieve the goal of inhibiting the formation of lithium dendrites, alleviating volume expansion, and inhibiting shuttles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] On the other hand, the present invention also provides a method for preparing a room-temperature all-liquid lithium-sulfur battery, comprising the following steps:

[0038] Step S1: making a room temperature liquid alloy negative electrode;

[0039] Step S2: making a diaphragm;

[0040] Step S3: making a liquid polysulfide positive electrode;

[0041] Step S4: making a current collector;

[0042] Step S5: Inject the room temperature liquid alloy negative electrode and the liquid polysulfide positive electrode into the replaceable membrane H-type electrolytic cell, insert the foil electrode into the room temperature liquid alloy negative electrode, and put the current collector on the lead clip and immerse in the liquid polysulfide positive electrode. The diaphragm is sandwiched between the positive electrode pool and the negative electrode pool, and the H-type electrolytic cell is sealed as a whole to form the room temperature all-liquid lithium-sulfur battery.

[00...

Embodiment 1

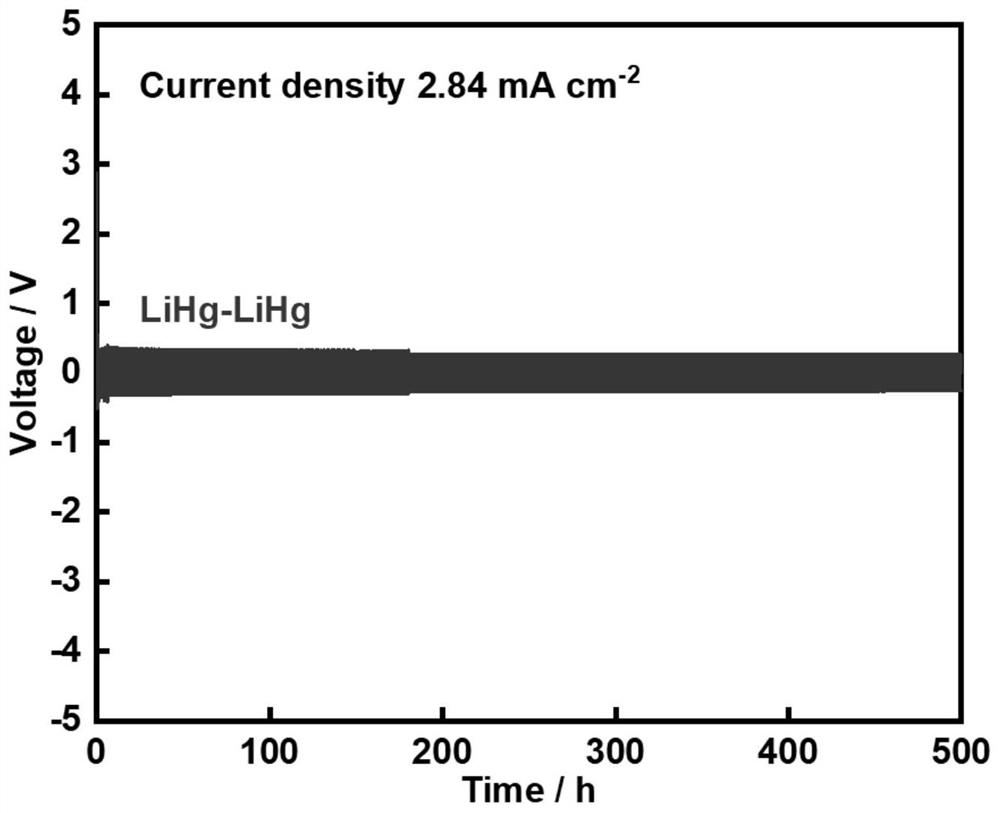

[0060] (1) Take 15 mg of metal lithium from which the oxide film has been removed, add it to 0.733 g of metal mercury, and let it stand for 24 hours to obtain a room temperature liquid alloy anode;

[0061] (2) Mix 1 g of boron nitride and 1 g of guanidine carbonate and ball mill for 48 h to obtain a uniformly mixed powder, add 20 mg of the mixed powder to 20 ml of NMP, and stir mechanically for 12 h to obtain a stable and uniform dispersion A; The ion battery diaphragm is used as filter paper, the dispersion A is filtered by suction, the NMP on the diaphragm is washed away with deionized water, and the lithium ion battery diaphragm with boron nitride coating can be obtained after the diaphragm is dried;

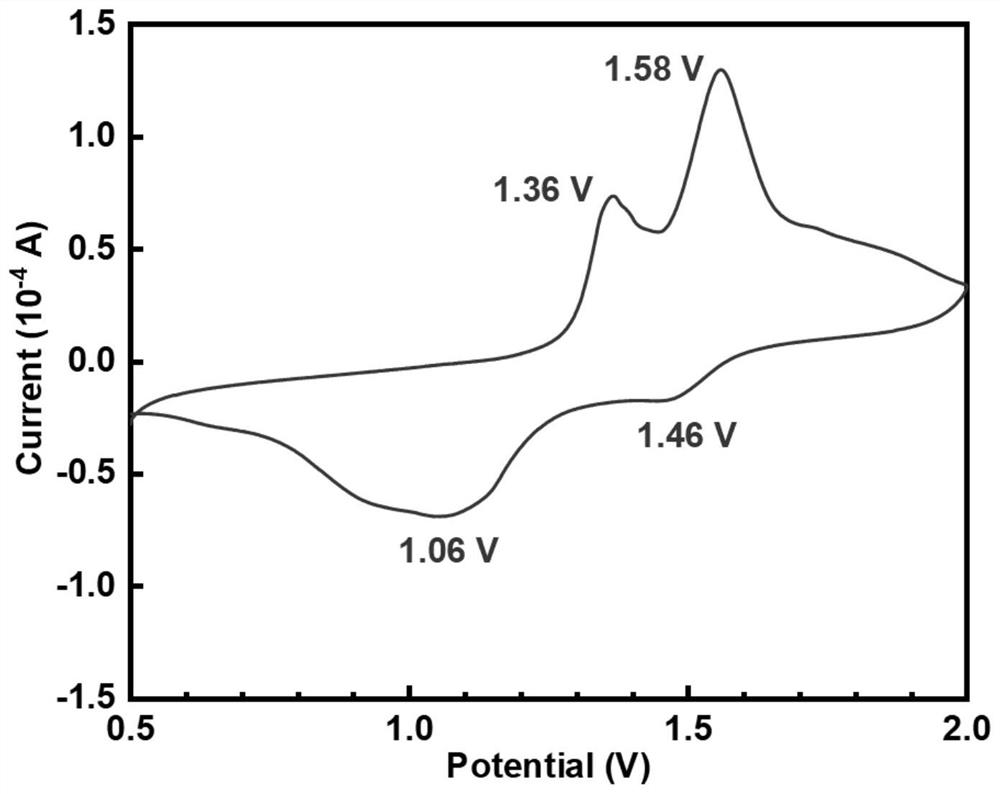

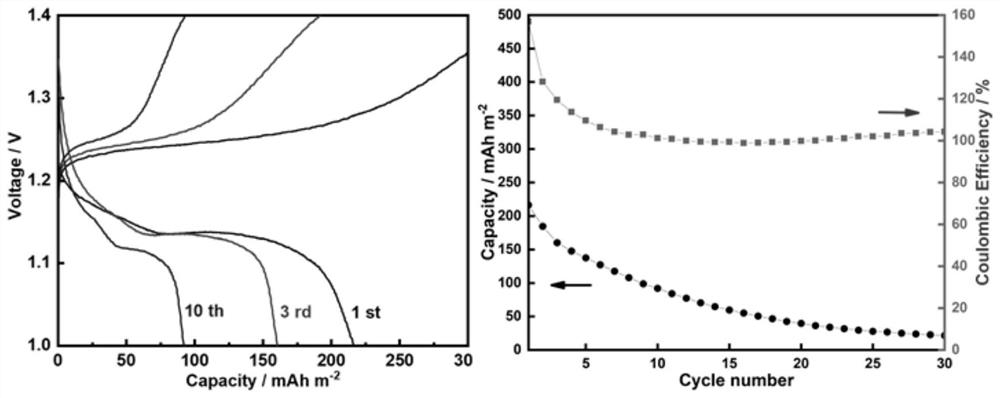

[0062] (3) Use an H-type electrolytic cell to assemble an ordinary lithium-sulfur battery, and short-circuit the positive and negative electrodes for discharge. The polysulfides will diffuse into the electrolyte, and the electrolyte will turn brown. The electrolyte was colle...

Embodiment 2

[0066] (1) Take 90 mg of metal lithium from which the oxide film has been removed, add it to 4.398 g of metal mercury, and let it stand for 24 hours to obtain a room temperature liquid alloy anode;

[0067] (2) Mix 2 g of boron nitride and 2 g of guanidine carbonate and ball mill for 48 h to obtain a uniformly mixed powder. Add 50 mg of the mixed powder to 50 ml of NMP and stir mechanically for 12 h to obtain a stable and uniform dispersion A; The ion battery separator is used as filter paper, the dispersion A is filtered by suction, the NMP is washed away with deionized water, and the lithium ion battery separator with boron nitride coating can be obtained after drying the separator;

[0068] (3) Use an H-type electrolytic cell to assemble an ordinary lithium-sulfur battery, and short-circuit the positive and negative electrodes for discharge. The polysulfides will diffuse into the electrolyte, and the electrolyte will turn brown. The electrolyte was collected, 20 mg of eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com